Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

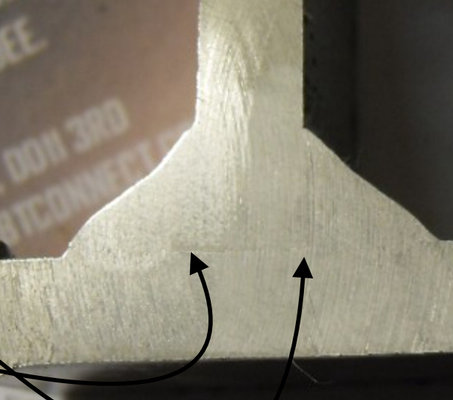

Not as much root as I would have liked though but at east it does show that using the polishing mop to buff it is not the best as it rounds the edges and doesn't show the section correctly. With milling the face it preserves all of that.

Going to have to go get some more pickling paste, suppose I have it for about 10years so it has done not too bad ;d

Going to have to go get some more pickling paste, suppose I have it for about 10years so it has done not too bad ;d

, taking time out to post on here is appreciated.arther

, taking time out to post on here is appreciated.arther