Richard.

Member

- Messages

- 18,043

- Location

- Cambridgeshire

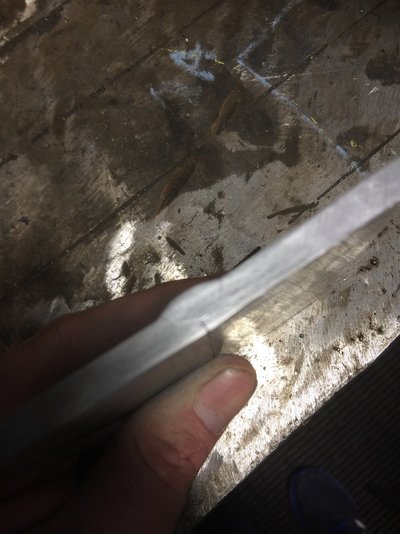

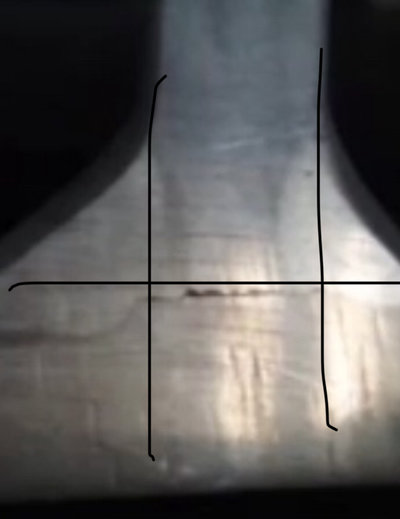

Set up 2 machines to suit a lump of 4-6mm Alu with current not been comparable and the mig will take that I can tell you now especially if you can set yourself a hot start to avoid that cold lump on strike up.

I think to get that sound weld on 4-6 mm Alu the mig is going to be putting out a lump more current than the tig will be mind. I remember you saying you weld 4mm at 120. This is very low to me I’d be 150ish but even then the mig won’t be doing much around that. On the 6mm I’d be around 200 joint depending. I think with a mig I’d be another 20-40 amps on top of that to get a sound joint. Again though coupon size and joint makes this all variable as you know. I’ll have a blast too with our migs and tigs and see if I get something similar.

Yes I’d be around your balance and frequency settings too at those current levels. 80% en and 80hz roughly would be my preference.

I think to get that sound weld on 4-6 mm Alu the mig is going to be putting out a lump more current than the tig will be mind. I remember you saying you weld 4mm at 120. This is very low to me I’d be 150ish but even then the mig won’t be doing much around that. On the 6mm I’d be around 200 joint depending. I think with a mig I’d be another 20-40 amps on top of that to get a sound joint. Again though coupon size and joint makes this all variable as you know. I’ll have a blast too with our migs and tigs and see if I get something similar.

Yes I’d be around your balance and frequency settings too at those current levels. 80% en and 80hz roughly would be my preference.