Hi Paul, did you ever get any further with this? I bought this welder a couple years ago. Hardly used it and just out of warranty the feed stopped working. Annoying as I just can't justify spending out more money on a new MIG for the amount I use it

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kende no wire feed

- Thread starter PaulC7

- Start date

DanielW

Member

- Messages

- 2,250

- Location

- Merseyside Straightjacket user

Back of the PCB on the white plug rail,this looks like a bad soldered joint? scrape back the tracking and link/solder it with a thickish piece of wire from track to lug.

this is the blue wire to motor and if the tracking has a dry joint at the lug? then there will be no feed.

this is the blue wire to motor and if the tracking has a dry joint at the lug? then there will be no feed.

DanielW

Member

- Messages

- 2,250

- Location

- Merseyside Straightjacket user

Hi Paul, did you ever get any further with this? I bought this welder a couple years ago. Hardly used it and just out of warranty the feed stopped working. Annoying as I just can't justify spending out more money on a new MIG for the amount I use it

Check for dry joints under a good magnfier or scrape back the trackings and resolder.

NotANormalCoder

Retired fixer of welders

- Messages

- 315

- Location

- Surbiton - Surrey -UK

A word of caution - some of these Chinese boards use a weird latching relay to drive the main (contactor) relay. Make sure that you get the right type!

I have no idea why they do this, it only increases the component count. I have rewired some boards a while back to accept a 'standard' non-latching relay but I can't remember how I did it.

Dave

I have no idea why they do this, it only increases the component count. I have rewired some boards a while back to accept a 'standard' non-latching relay but I can't remember how I did it.

Dave

Hi DaveA word of caution - some of these Chinese boards use a weird latching relay to drive the main (contactor) relay. Make sure that you get the right type!

I have no idea why they do this, it only increases the component count. I have rewired some boards a while back to accept a 'standard' non-latching relay but I can't remember how I did it.

Dave

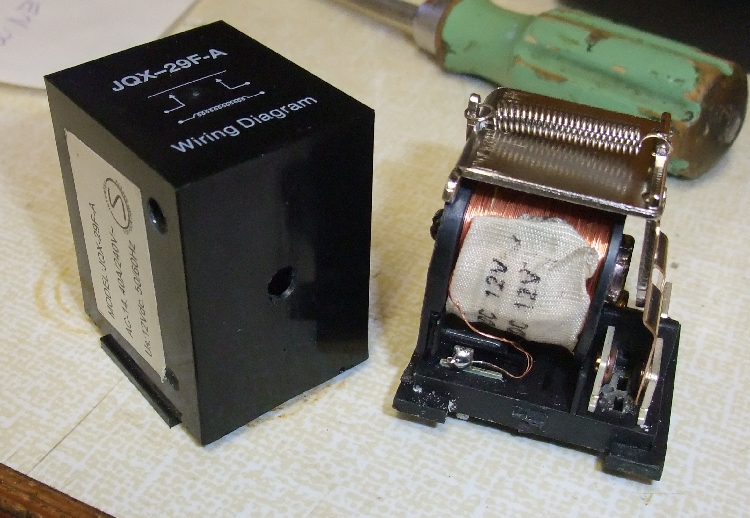

Do you have any idea were I can get this relay or an equivelent (JQX-29F-A) its a 4 pin Lable says AC-14.40a?240v Us:12vdc. 50/60Hz

DanielW

Member

- Messages

- 2,250

- Location

- Merseyside Straightjacket user

Do you have the relay out? if so can post pics of the pins and the legend print you have specified.

This is in china but it looks the same rating? but depends on pin layout,I suspect that if you did find an equivalent you'd still have rewire the relay up to appropriate pins.

http://www.ebay.co.uk/itm/JQX-38F-D...2530&tpos=bottom&ttype=coupon&talgo=undefined

This is in china but it looks the same rating? but depends on pin layout,I suspect that if you did find an equivalent you'd still have rewire the relay up to appropriate pins.

http://www.ebay.co.uk/itm/JQX-38F-D...2530&tpos=bottom&ttype=coupon&talgo=undefined

DanielW

Member

- Messages

- 2,250

- Location

- Merseyside Straightjacket user

The above is 11pins but it comes with a base thats has screw down post,pretty ideal really as you can wire it from PCB to relay but the catch is whether its rating/power is the same?

I have Kende 150,gonna take snaps shots of the PCB and components just in case mine goes west.

I have Kende 150,gonna take snaps shots of the PCB and components just in case mine goes west.

NotANormalCoder

Retired fixer of welders

- Messages

- 315

- Location

- Surbiton - Surrey -UK

A little googlin' suggests that this is one of many odd relays that Chineses manufacturers use. I'd look at the range of heavy automotive relays from RS (www.rswww.com) as they generally have 12vDC coils. Single pole, single throw 30A should be enough for a 240v welder. As above, nail it to the case and run wires from the board. 2.5mm2 for the contacts and any old light wire for the coil.

Otherwise, waste a ton of time on AliBaba or similar.

Dave

Otherwise, waste a ton of time on AliBaba or similar.

Dave

mike 109444

Member

- Messages

- 4,859

Hi Mikey and welcome

Can you post a pic of inside machine and then maybe can point you to what to check. Could be the cutout device mounted on the main transformer as it is there to sense the transformer getting to hot and would go OPEN, then cool and close. It may fail in the open position.

Can you post a pic of inside machine and then maybe can point you to what to check. Could be the cutout device mounted on the main transformer as it is there to sense the transformer getting to hot and would go OPEN, then cool and close. It may fail in the open position.

DanielW

Member

- Messages

- 2,250

- Location

- Merseyside Straightjacket user

no answer to this???

Probably because you're not helping by posting a good pic of the PCB components and the tracking side of the PCB. plus internal shots of the welder.

Mike 109444 did ask.

mike 109444

Member

- Messages

- 4,859

As you HAVE wire feed but no ARC you have a very different fault. If you meter between the ground clamp and the welding tip (back off wire feed speed! do you get ANY DC voltage. Yo should get between 14 to 30 VDC but if you get 0v or close to that then you may have a broken cable between the output of the main transformer, diode pack, ground clamp socket on front, or weld power feed by the wire feed motor (could even be the torch) Is it a Euro torch?

mike 109444

Member

- Messages

- 4,859

If you are referring to post number 1 then anyone's guess...

If you check it out in much the same way then post results. (remember to disconnect the motor if you test it with a separate 12v power supply/battery).

and POST PICS!!!!

and welcome BTW

If you check it out in much the same way then post results. (remember to disconnect the motor if you test it with a separate 12v power supply/battery).

and POST PICS!!!!

and welcome BTW

Hello Guys, I am a newbie in this forum.

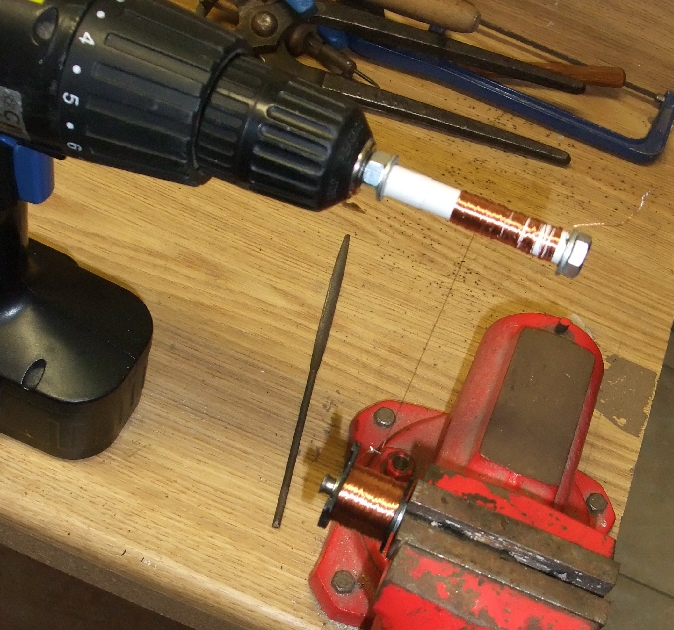

The problem is inside of the relay JQX-29F-A. This at least worked for me. The wire is open circuit in the coil of the relay.

When searching for this relay, I have found that no one provides them right now.

But the relay is easy to disassemble and rewind.

When unwinding the wire I have found water in the middle of the coil winding. The wire was kind of rusted at several points and at these points it was interrupted.

I think humidity soaks inside of the relay due to temperature change and can not get out. I made some holes in the plastic cover in order to keep humidity out.

Hopefully dust will not come in.

I hope this will work for you as well.

Good luck Martin

The problem is inside of the relay JQX-29F-A. This at least worked for me. The wire is open circuit in the coil of the relay.

When searching for this relay, I have found that no one provides them right now.

But the relay is easy to disassemble and rewind.

When unwinding the wire I have found water in the middle of the coil winding. The wire was kind of rusted at several points and at these points it was interrupted.

I think humidity soaks inside of the relay due to temperature change and can not get out. I made some holes in the plastic cover in order to keep humidity out.

Hopefully dust will not come in.

I hope this will work for you as well.

Good luck Martin

Hello Guys, I am a newbie in this forum.

The problem is inside of the relay JQX-29F-A. This at least worked for me. The wire is open circuit in the coil of the relay.

When searching for this relay, I have found that no one provides them right now.

But the relay is easy to disassemble and rewind.

When unwinding the wire I have found water in the middle of the coil winding. The wire was kind of rusted at several points and at these points it was interrupted.

I think humidity soaks inside of the relay due to temperature change and can not get out. I made some holes in the plastic cover in order to keep humidity out.

Hopefully dust will not come in.

I hope this will work for you as well.

Good luck Martin

hi im new here just happen to buy ozito mwr 135 . mine is same it clicks no feed no spark i open these big relay and lots of moisture insode and the coil is open . other than rewind whats the other option?