PaulC7

Member

- Messages

- 139

- Location

- Liverpool, England

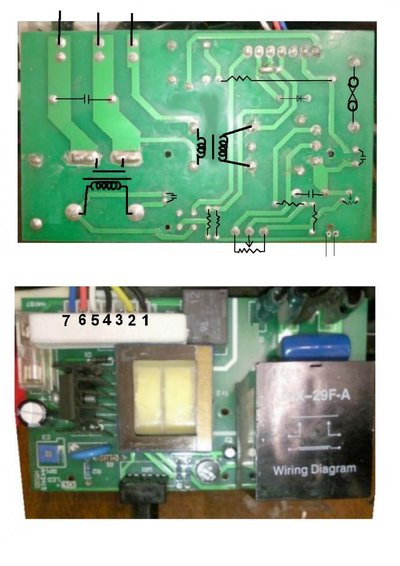

Got a Kende 105/f for nothing as it has a wire feed problem even though its not been used much.

Turns on an fan kicks in and when pulling trigger a clicking from a small black box can be heard.

Had a good look inside, all wires are fine, all connections are good, but noticed the wire feed motor wasnt running... so connected 12v battery to motor and all worked fine but a componant glew red and started smoking heavily.

Took off the part which i was told is a resistor... RX1-10 0.5 +5% an bought a 10w w/w 0.56r

After fitting and putting everything back together the problem isnt solved.

Im not an electrical person by any means so any help sorting out the problem would be great thanks.

Turns on an fan kicks in and when pulling trigger a clicking from a small black box can be heard.

Had a good look inside, all wires are fine, all connections are good, but noticed the wire feed motor wasnt running... so connected 12v battery to motor and all worked fine but a componant glew red and started smoking heavily.

Took off the part which i was told is a resistor... RX1-10 0.5 +5% an bought a 10w w/w 0.56r

After fitting and putting everything back together the problem isnt solved.

Im not an electrical person by any means so any help sorting out the problem would be great thanks.

]

]