You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

flat welds

- Thread starter flange jockey

- Start date

puddles those roots are realy coming together good,,flange what gap is on the picture with the bullets?and how you getting on with 7018s...im doing a lot of work tig rooting and fill,cap with 18s at the minute so il try post some pics.

fnc

7018 can be a real pain to root with unless you are using them regularly, I always found 7016 a much easier Low Hy to root with. 7018 has a much thicker flux coating than the 7016 which tends to make them difficult to access the root faces unless you really push them in. 7018 is also more fluid than the 7016 so root consistency is not easy for someone new to them. I believe that the difference between 7016 and 7018 is that 7018 has iron powder added to the flux to increase recovery, this would explain the thicker flux and increased fluidity. If I had a choice on a full stick LowHy butt I would use 7016 for the root and 7018 for fill and cap, favourite rooting rod was always Phillips 56S, which I think is Filarc now?

flange jockey

Member

- Messages

- 173

jes jay where did you dig this one up from, i havn,t caught much from puddles lately but i know from other sites he has posted some great looking welds.good to hear you are keeping busy, things here have slowed down a bit. i explained to the lads here when i first visited i have always been, lets say vague around rods etc. if a low hi root has been required in the past i have welded with the rods supplied for the said job or test. now through reading these boards i have a better understanding of what i have used in the past, i know from the feel that i have welded with 7018 before, on various jobs.while im at it , anyone familiar with philips kv5 is it 7018? just like busa i find 7016 a better option on roots and funny enough ,the one i have most experience with is filarc, i think i posted a pic before. as mentioned the thicker flux gives you the impression your not getting far enough into the root face with 7018 it takes a bit of getting used to

i havn,t caught much from puddles lately but i know from other sites he has posted some great looking welds.good to hear you are keeping busy, things here have slowed down a bit. i explained to the lads here when i first visited i have always been, lets say vague around rods etc. if a low hi root has been required in the past i have welded with the rods supplied for the said job or test. now through reading these boards i have a better understanding of what i have used in the past, i know from the feel that i have welded with 7018 before, on various jobs.while im at it , anyone familiar with philips kv5 is it 7018? just like busa i find 7016 a better option on roots and funny enough ,the one i have most experience with is filarc, i think i posted a pic before. as mentioned the thicker flux gives you the impression your not getting far enough into the root face with 7018 it takes a bit of getting used to . that gap on the bullets was 4mm jay, would you let the guy who tacked it near the rootface

. that gap on the bullets was 4mm jay, would you let the guy who tacked it near the rootface . get those pics up. f/j

. get those pics up. f/j

i havn,t caught much from puddles lately but i know from other sites he has posted some great looking welds.good to hear you are keeping busy, things here have slowed down a bit. i explained to the lads here when i first visited i have always been, lets say vague around rods etc. if a low hi root has been required in the past i have welded with the rods supplied for the said job or test. now through reading these boards i have a better understanding of what i have used in the past, i know from the feel that i have welded with 7018 before, on various jobs.while im at it , anyone familiar with philips kv5 is it 7018? just like busa i find 7016 a better option on roots and funny enough ,the one i have most experience with is filarc, i think i posted a pic before. as mentioned the thicker flux gives you the impression your not getting far enough into the root face with 7018 it takes a bit of getting used to

i havn,t caught much from puddles lately but i know from other sites he has posted some great looking welds.good to hear you are keeping busy, things here have slowed down a bit. i explained to the lads here when i first visited i have always been, lets say vague around rods etc. if a low hi root has been required in the past i have welded with the rods supplied for the said job or test. now through reading these boards i have a better understanding of what i have used in the past, i know from the feel that i have welded with 7018 before, on various jobs.while im at it , anyone familiar with philips kv5 is it 7018? just like busa i find 7016 a better option on roots and funny enough ,the one i have most experience with is filarc, i think i posted a pic before. as mentioned the thicker flux gives you the impression your not getting far enough into the root face with 7018 it takes a bit of getting used to . that gap on the bullets was 4mm jay, would you let the guy who tacked it near the rootface

. that gap on the bullets was 4mm jay, would you let the guy who tacked it near the rootface . get those pics up. f/j

. get those pics up. f/jflange jockey

Member

- Messages

- 173

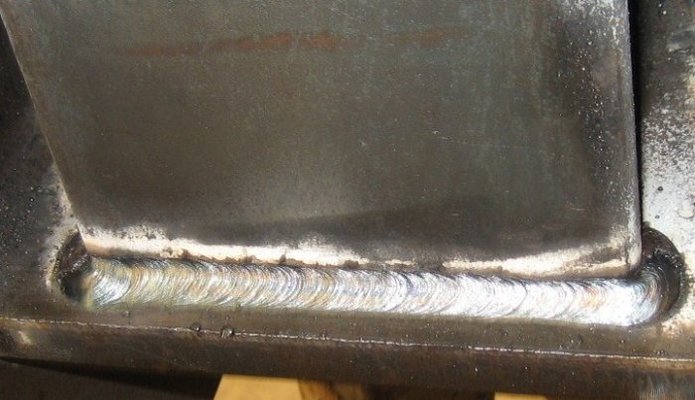

funny looking back on this one how impatient some of you guys were to talk about pipe.  heres some flat plate work from recently, 4mm 150 amps. f/j

heres some flat plate work from recently, 4mm 150 amps. f/j

heres some flat plate work from recently, 4mm 150 amps. f/j

heres some flat plate work from recently, 4mm 150 amps. f/j- Messages

- 17,663

Fabulous as always F/J

One question I don't recall has been asked is what machines do you use?

I'm guessing several but there must be one or two you use most often?

It's only a curiosity question, I'll bet you could lay a perfect bead down with a Cosmo.

One question I don't recall has been asked is what machines do you use?

I'm guessing several but there must be one or two you use most often?

It's only a curiosity question, I'll bet you could lay a perfect bead down with a Cosmo.

weldingscotty803

what you staring at??????????

- Messages

- 1,170

fj, when your dound flat plate like the above, do you drag the rod on the workpiece or 1-2mm above? if you know what i mean.

good to see some pics again, peeeeeeeeeeeeeeeelllllllllllllllllllllllllllllllleeeeeeeeeeeeeeeerrrrrrrrrrrr, sorry

good to see some pics again, peeeeeeeeeeeeeeeelllllllllllllllllllllllllllllllleeeeeeeeeeeeeeeerrrrrrrrrrrr, sorry

flange jockey

Member

- Messages

- 173

cheers wooz, ill try to find a few pics and keep you posted on that mate, W/E we have 4 of those in the shop, they would be the ones i would use most. scotty the rod tip is pointing very slightly back and floating in the pool, its like gravity feed with you in control of the speed of travel, you only need to hold the gear very lightly. heres a couple more. f/j

anyone familiar with philips kv5 is it 7018?

Never come across a Philips KV5 f/j but Esab did a KV5, with 1 1/4% Chrome for low alloyed steels, E8015 or E8015-B was the AWS Number.