You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

(1972) BMW 2002 Tii

- Thread starter B1N9S

- Start date

B1N9S

Member

- Messages

- 322

- Location

- Conwy, UK

Done some more on the bulkhead repairs. Fabbed a repair panel for the big hole I made !!! Needs some more work, but quite chuffed with it at the moment.

All the rot removed. There is still some in the footwell, where the master cylinder has leaked, but I will do the repair in two pieces, so I can retain the position of the steering column housing/bracket.

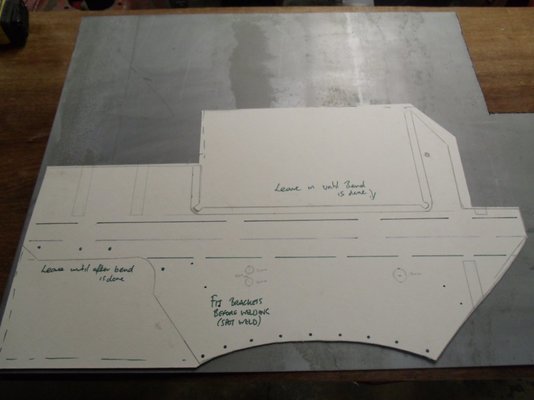

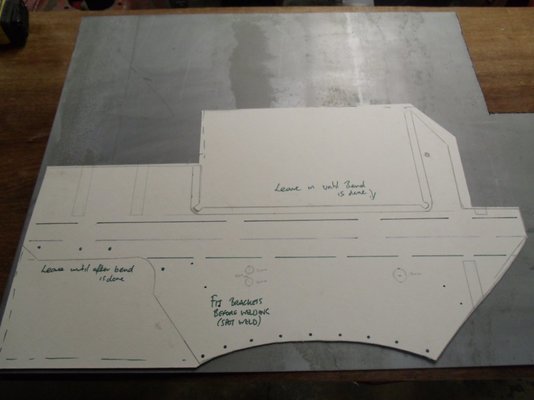

Cardboard template made.

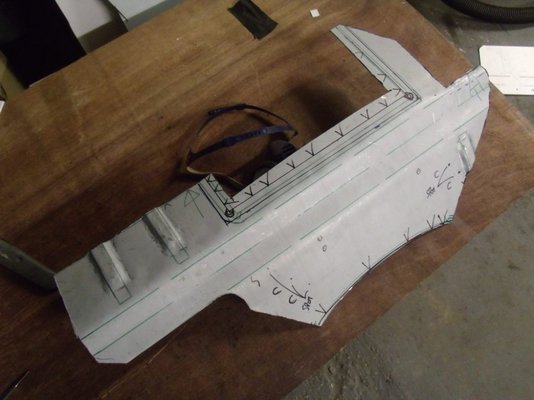

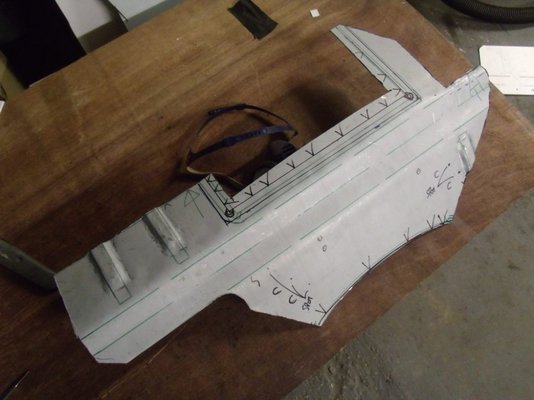

Steel piece made. Needs some more fettling.

First trial fit. Now it needs to have some clips and holes put in it.

Once I have this repair done. I will prep and paint the whole area, before I replace the scuttle panel, as access will be much easier as it is.

All the rot removed. There is still some in the footwell, where the master cylinder has leaked, but I will do the repair in two pieces, so I can retain the position of the steering column housing/bracket.

Cardboard template made.

Steel piece made. Needs some more fettling.

First trial fit. Now it needs to have some clips and holes put in it.

Once I have this repair done. I will prep and paint the whole area, before I replace the scuttle panel, as access will be much easier as it is.

Flathead_Dave

Member

- Messages

- 325

You've done a great job on all of it,but that last piece is brilliant,there's a lot of tricky shapes there.

You're prob ahead of me here,but before you weld up the outer front panels,drop the bonnet on.

No amount of adjustment can make up for the hole being the wrong size.

Keep up the good work.

You're prob ahead of me here,but before you weld up the outer front panels,drop the bonnet on.

No amount of adjustment can make up for the hole being the wrong size.

Keep up the good work.

B1N9S

Member

- Messages

- 322

- Location

- Conwy, UK

You've done a great job on all of it,but that last piece is brilliant,there's a lot of tricky shapes there.

You're prob ahead of me here,but before you weld up the outer front panels,drop the bonnet on.

No amount of adjustment can make up for the hole being the wrong size.

Keep up the good work.

Cheers Dave. I'll make sure I do that mate.

jpmillermatic

Member

- Messages

- 1,094

wow, just wow!

JP

JP

B1N9S

Member

- Messages

- 322

- Location

- Conwy, UK

That's a fairly heroic rescue that; you seem to have replaced about 50% of the sheet metal! Proper job.

Haha !! Yeh..Almost !!! To be honest I seriously toyed with the idea of reshelling it, but that is just a legal and resale minefield and as it is a Tii model, it is worth saving.

Cheers guys.

Hope to have the footwell section and Chassis rail done over the weekend.

jpmillermatic

Member

- Messages

- 1,094

inspiring work

JP

JP

Did you see the recent video doing the rounds on a chap in the US with a 2002?

I just tried to find it and realised there are an awful lot of these cars undergoing restoration. I really enjoy reading about projects like this. Keep up the good work and good luck!

I just tried to find it and realised there are an awful lot of these cars undergoing restoration. I really enjoy reading about projects like this. Keep up the good work and good luck!

B1N9S

Member

- Messages

- 322

- Location

- Conwy, UK

I was about to take a break from doing the bodywork on this and start on rebuilding the subframes. But, I decided to just crack on and I will do the subframes later, when the car goes off to the bodyshop for paint and final finishing.

So, I have finished the bulkhead area and the drivers side footwell, floor panel and chassis rail and am currently working on reskinning the roof, which is going ok. So, here's a few more pics.

This is how the chassis looked - Pretty nasty eh !!!

I had already cut out the section from my donor car. Just seeing how it lies with the pattern floor panel.

Old horrible section cut back.

I decided to give the joint added strength, by filleting it and plug welding this to both sides. It was actually plug welded all the way around, not just at the top. I hadn't finished drilling in this pic !!!

Test fitted.

Welded in and tidied up.

So, next job, was to make a panel for the section of footwell in the drivers side.

More nastiness !!!

So, I made a repair panel. It's not totally original looking, but, this area is not really seen, so it's the best I could do with limited tools.

And, a pic of the whole floor section under construction. It is now almost finished, I'll get more pics later. Nice to see the whole floor and chassis now nice and solid.

More pics of the roof reskin to follow.

So, I have finished the bulkhead area and the drivers side footwell, floor panel and chassis rail and am currently working on reskinning the roof, which is going ok. So, here's a few more pics.

This is how the chassis looked - Pretty nasty eh !!!

I had already cut out the section from my donor car. Just seeing how it lies with the pattern floor panel.

Old horrible section cut back.

I decided to give the joint added strength, by filleting it and plug welding this to both sides. It was actually plug welded all the way around, not just at the top. I hadn't finished drilling in this pic !!!

Test fitted.

Welded in and tidied up.

So, next job, was to make a panel for the section of footwell in the drivers side.

More nastiness !!!

So, I made a repair panel. It's not totally original looking, but, this area is not really seen, so it's the best I could do with limited tools.

And, a pic of the whole floor section under construction. It is now almost finished, I'll get more pics later. Nice to see the whole floor and chassis now nice and solid.

More pics of the roof reskin to follow.

B1N9S

Member

- Messages

- 322

- Location

- Conwy, UK

So, here are some pics of the WIP, roof reskinning.

Remember this car had a Webasto sunroof. Which do look great and are a nice addition to a warm climate. But here in the damp, cold UK. I think they are just trouble waiting to happen (and they cost a small fortune to replace !!). So with the best intentions I decided to reskin the roof as it wasn't looking too healthy after 43 yrs of UK weather underneath the vinyl !!!

So, again my donor shell, gave up something !! This time, a very good condition roof. The donor deserves a mention, I think. It was a 1972 2002, same build month as my Tii (January), wouldn't have been an economical shell to rebuild, so, it was put to very good use. I almost used the whole thing at one stage !! It is nice it is of almost identical age though.

Old roof - Best pic I have sorry !!! Excuse the sill resting on it !!

Old roof all removed back to the frame. There was also rot creeping down the A pillar on the drivers side, so this is addressed too. This took a lot of careful grinding and drilling out spot welds, but I am more than happy. Absolutely bare minimum damage to the remaining area. Having the donor helped here, as you can see where you need to trim off.

Replacement cross members.

Starting to deconstruct the donor panel.

Fully stripped (very flimsy at this stage, two people are best to move it, or you risk kinking it !).

I treated the interior of the panel with Dinitrol rust treatment for the light surface rust. It will get epoxy primer, before final fitting.

Quick test fit. Plenty of work to do, but it's going well. I have a spot welder to fit this panel and all the other external stuff, so as long as they align, it should be plain sailing !! :shock:

Remember this car had a Webasto sunroof. Which do look great and are a nice addition to a warm climate. But here in the damp, cold UK. I think they are just trouble waiting to happen (and they cost a small fortune to replace !!). So with the best intentions I decided to reskin the roof as it wasn't looking too healthy after 43 yrs of UK weather underneath the vinyl !!!

So, again my donor shell, gave up something !! This time, a very good condition roof. The donor deserves a mention, I think. It was a 1972 2002, same build month as my Tii (January), wouldn't have been an economical shell to rebuild, so, it was put to very good use. I almost used the whole thing at one stage !! It is nice it is of almost identical age though.

Old roof - Best pic I have sorry !!! Excuse the sill resting on it !!

Old roof all removed back to the frame. There was also rot creeping down the A pillar on the drivers side, so this is addressed too. This took a lot of careful grinding and drilling out spot welds, but I am more than happy. Absolutely bare minimum damage to the remaining area. Having the donor helped here, as you can see where you need to trim off.

Replacement cross members.

Starting to deconstruct the donor panel.

Fully stripped (very flimsy at this stage, two people are best to move it, or you risk kinking it !).

I treated the interior of the panel with Dinitrol rust treatment for the light surface rust. It will get epoxy primer, before final fitting.

Quick test fit. Plenty of work to do, but it's going well. I have a spot welder to fit this panel and all the other external stuff, so as long as they align, it should be plain sailing !! :shock:

B1N9S

Member

- Messages

- 322

- Location

- Conwy, UK

Finally got the roof spot welded on today. I was holding off, while I rewired the consumer unit in the garage to take the extra load of the spot welder. I ended up adding a dedicated socket on a short run of 6mm cable on a 32A breaker !! The garage is still there, so I guess it was fine !!

The pics don't show ALL of the spots, there was another round afterwards !!

The rear corner joint was originally leaded. I know this, because I tried welding one side and the lead melted away and the weld was a total mess, as was/is the joint !!!

What is the best way to attack this ? Should I 're' lead it ? Or is that just going to end up in a mess ? Help ?

A skim of filler required here.

Chuffed to bits with it.

The pics don't show ALL of the spots, there was another round afterwards !!

The rear corner joint was originally leaded. I know this, because I tried welding one side and the lead melted away and the weld was a total mess, as was/is the joint !!!

What is the best way to attack this ? Should I 're' lead it ? Or is that just going to end up in a mess ? Help ?

A skim of filler required here.

Chuffed to bits with it.

Springerdinger

memoirs of the mediocre diy mechanic

- Messages

- 435

- Location

- UK nr Southam

Really nice work.

Great templates I think I need to step up my template game after seeing yours.

I had the same webasto roof challenge you did a nice job

Great templates I think I need to step up my template game after seeing yours.

I had the same webasto roof challenge you did a nice job

B1N9S

Member

- Messages

- 322

- Location

- Conwy, UK

Are you going to use solder for the filling or just isopon or the like ?

I was going to use some 'Dinitrol' alu filler for the A posts, but I'm not 100% sure how to tackle the C pillar joint. Any ideas. It was leaded in the factory. Can I solder over the top of that ? I am guessing the original stuff will run off if I apply heat ?

Parm

Respect The Sound System

- Messages

- 17,901

- Location

- Towcester

Done some more on the bulkhead repairs. Fabbed a repair panel for the big hole I made !!! Needs some more work, but quite chuffed with it at the moment.

All the rot removed. There is still some in the footwell, where the master cylinder has leaked, but I will do the repair in two pieces, so I can retain the position of the steering column housing/bracket.

View attachment 75369

View attachment 75372

Cardboard template made.

View attachment 75371

Steel piece made. Needs some more fettling.

View attachment 75373

First trial fit. Now it needs to have some clips and holes put in it.

View attachment 75374

Once I have this repair done. I will prep and paint the whole area, before I replace the scuttle panel, as access will be much easier as it is.

That's a realy neat panel and great template, would you mind sharing how the panel was made, ie lots of fancy kit or home workshop tools

C

Chris Stevens

Guest

I was going to use some 'Dinitrol' alu filler for the A posts, but I'm not 100% sure how to tackle the C pillar joint. Any ideas. It was leaded in the factory. Can I solder over the top of that ? I am guessing the original stuff will run off if I apply heat ?

Unless you lead all the exterior joints, there is a possibility that rot will eventually appear through the paint. When leading there is only a need for a thin skim of lead over the actual joint to seal it, and final finish using filler. Leading is very easy, and not quite ever been able to work out why people go to so much trouble restoring old cars, and then risk future corrosion by not leading the joints?