B1N9S

Member

- Messages

- 322

- Location

- Conwy, UK

Well, I may as well start a thread on my project. It has been ongoing for about 18 months, but only the last 12 have been in anger !!! Once I managed to get myself a decent place to work on it.

I bought the car, knowing it needed a 'bit' of work and intended on it being a nice little project, but as with most 70's cars...the more you dig, the more rust you will find !!! I think I knew when I bought it, but went with my heart rather than my head and bought it without really giving it a good look over...idiot !!. But, it is an early model and was all original, matching numbers car, so if I didn't take it on, someone else would AND the guy had a second 1602 project, so I took them both !!!

I should explain, that I am not a welder, or bodyshop guy, or even in the car trade. I work as a radio engineer, so I am on a steep learning curve and welcome ANY comments, better if they are constructive.

So, here is the car when I bought it. Doesn't look too bad !! Eh !!

So initially the plan was a quick tidy up, get the bad areas welded up by a pro and off she goes. But once I started removing the interior and saw some old poor MOT patching, I knew I would need to dig deeper and decided to wait till, I had somewhere better to work on it. We were looking to move house anyway, but this kind of pushed us along and I now needed to find a house with a decent garage.

So, we finally moved 6 months later and I inherited a nice double garage with an inspection pit !!! Bonus !!! I have since extended the rear of the garage with a 6x3M extension, so it is a really good size. So the tear down began properly about 12 months ago.

Engine out:

Subframes out:

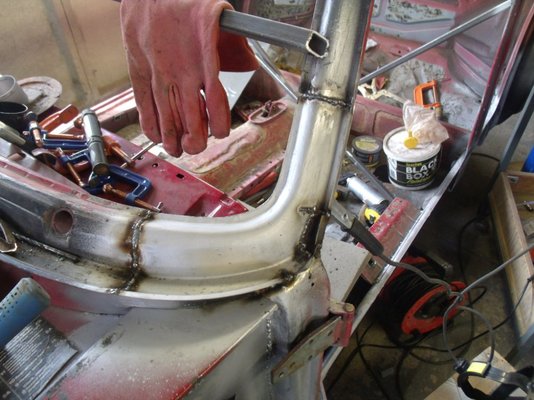

And then, onto the body inspection......

I bought the car, knowing it needed a 'bit' of work and intended on it being a nice little project, but as with most 70's cars...the more you dig, the more rust you will find !!! I think I knew when I bought it, but went with my heart rather than my head and bought it without really giving it a good look over...idiot !!. But, it is an early model and was all original, matching numbers car, so if I didn't take it on, someone else would AND the guy had a second 1602 project, so I took them both !!!

I should explain, that I am not a welder, or bodyshop guy, or even in the car trade. I work as a radio engineer, so I am on a steep learning curve and welcome ANY comments, better if they are constructive.

So, here is the car when I bought it. Doesn't look too bad !! Eh !!

So initially the plan was a quick tidy up, get the bad areas welded up by a pro and off she goes. But once I started removing the interior and saw some old poor MOT patching, I knew I would need to dig deeper and decided to wait till, I had somewhere better to work on it. We were looking to move house anyway, but this kind of pushed us along and I now needed to find a house with a decent garage.

So, we finally moved 6 months later and I inherited a nice double garage with an inspection pit !!! Bonus !!! I have since extended the rear of the garage with a 6x3M extension, so it is a really good size. So the tear down began properly about 12 months ago.

Engine out:

Subframes out:

And then, onto the body inspection......

. So, Basically it goes like this:

. So, Basically it goes like this: