The_Yellow_Ardvark

I'm a citizen of Legoland travellin' incommunicado

- Messages

- 20,268

- Location

- Going Away.

I feel old now.The first new bike I bought was a CX500, yours is a later model with the reversed Comstar wheels.

View attachment 524670

I feel old now.The first new bike I bought was a CX500, yours is a later model with the reversed Comstar wheels.

View attachment 524670

$%$£&*& well done that. Years ago I found I had a crank bearing cap bolt hiding under rags in the parts box just as I was about to lower the engine in placeOr finding that fixing, at the end of a long rebuild. Then finding out it was meant to be fitted at the start.

To fit it means a strip down.

My good friend, you had engines back then?I made a sound turkey soup ready for bracing us against tomorrows bone chilling weather whilst at Fizzy's unit .

$%$£&*& well done that. Years ago I found I had a crank bearing cap bolt hiding under rags in the parts box just as I was about to lower the engine in place

IIRC April 1968 , still doing my apprenticeship , when at home on leave I stripped , cleaned , examined to the Nth degree & rebuilt my brothers 1958 .. A35 van engine after checking the bores and re ringing the pistons with Duoflex oil scraper rings.My good friend, you had engines back then?

My 4 pronged, old man's diggy thing. Following on from yesterday's what I broke post.

First time I've used the flux core mig/tig/MMA welder I bought from someone on here. Well impressed tbh with the strength, (if not the appearance) of the finished weld. 0.8mm flux cored at 90A. Far easier to use than my gassed Clarke 130TE.

View attachment 519258

View attachment 519259

Getting inside was awkward is my excuse here:

View attachment 519260

Place on level ground.Jack goes up ok but only to 80%. Needs bleeding & fluid change? Advice welcome.

so to finish this off, it deadjusted itself again the next time i drove it. today i took a bit of time to fit the replacement mech id had sitting on the bench a while. in the process of doing so i had to remove the steering control arm as its in the way of the lower bolt. not a issue, right?View attachment 515523

yay.

mot passed this morning. no problems.

shame they only test there once a week, made the timeline rather tight....

Had two "base" models, a CX500C and a Eurosport. All great bikesThe first new bike I bought was a CX500, yours is a later model with the reversed Comstar wheels.

View attachment 524670

Had two "base" models, a CX500C and a Eurosport. All great bikes

My first thought when I saw your pics was Mazak/Zamak, the zinc alloy - used for precision casting of carburettors and the like. It has that sort of sheen.Haven't fixed it yet, but this has just landed on the bench after a chain gave way and decimated the cheap cast ally housing for the shaft the chain was running...the drive is for the feed rollers on a thicknesser that my wood butcher father bought a few weeks ago.

2mm cast ally, seems weldable, not massively dirty. Will be repaired and modified a bit for some extra strength as the bit that broke off is just free floating and takes a reasonable load as the end bearing sits inside. The little broken off nub isn't needed so that's going to get chopped and filled over.

Only major concern is straightness and the bearing seatView attachment 524711View attachment 524713View attachment 524715

Tacked up at the moment, now to attack with the die grinder

This is off a zelcan branded planer thicknesser, although highly likely to be Chinese origin given the price of it.My first thought when I saw your pics was Mazak/Zamak, the zinc alloy - used for precision casting of carburettors and the like. It has that sort of sheen.

Anyway, as you know it's just about unweldable, won't glue with any strength, bloody 'orrible stuff.

... so fortunate if it's an aluminium alloy

There's the reason why all the dispatch riders used them back in the day. Well not all, I knew a huge great bloke who used an MZ250, and he went everywhere on that but he was the exception. His other bike was a Rickman CR1000, which is how I got to know him because I had one of those at the time as well.

What make is this POS I wonder?Spent an hour today fixing a sturdy jack that I was given a while ago. Declared faults were:

It goes up ok but won’t go down.

Turning the handle does nothing, you need to undo the valve manually with a lever.

View attachment 524752

Valve is now freed off ( odd - I stripped it and nothing was stuck??)

Also shimmed the internal hex drive in the handle so release now works.

New problems:

How do I straighten the bent return spring?

Jack goes up ok but only to 80%. Needs bleeding & fluid change? Advice welcome.

It all counts as progress

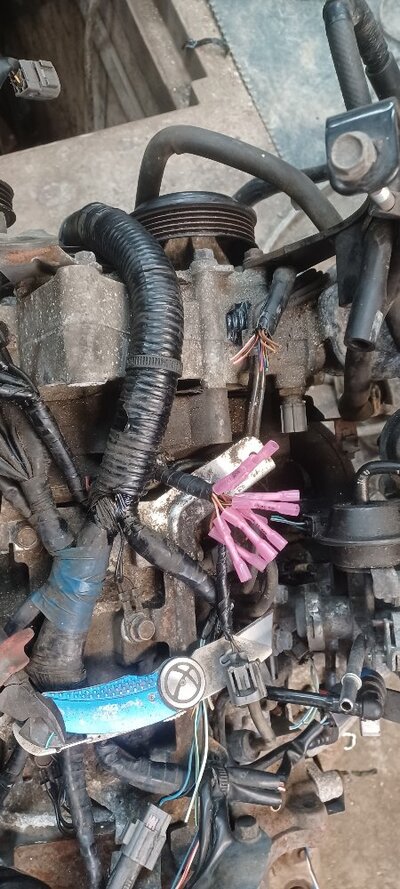

time to start fixing the partially ev swapped rx8. first job, repair the engine wiring loom and dress the engine.

what i started with...

View attachment 524887

gearbox loom repair

View attachment 524886

View attachment 524885

View attachment 524884

View attachment 524883

View attachment 524882