so worth the money then?Holes, plural! They converge at the tip. Lad's run his own tests and it lays down a much greater volume than the standard one.

View attachment 510893

- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- CAD/CAM, 3D Printing and Laser Cutting

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff your 3D printer has made today...

- Thread starter Dr.Al

- Start date

Onoff

In the land of the unfinished project I am King!

- Messages

- 13,250

- Location

- Sevenoaks, UK

so worth the money then?

I'll ask him when I see him but suffice to say he's not gone back to the original.

A couple I have purchased come with extra nozzles. I have not tried those yet anyway.It is a complete hotend. By comparison the standard bambu hotend is £14.

You don't just unscrew the nozzle like on an ender type printer.

I got back home and just used the same PetG but not through the AMS. Just pushed it in ., heated the hotend and pressed the extrude a few times.

Working a treat. actually its printing a hose connector @Onoff put me onto.. SO.............. I do think its the balance between PetG temps and PLA temps.

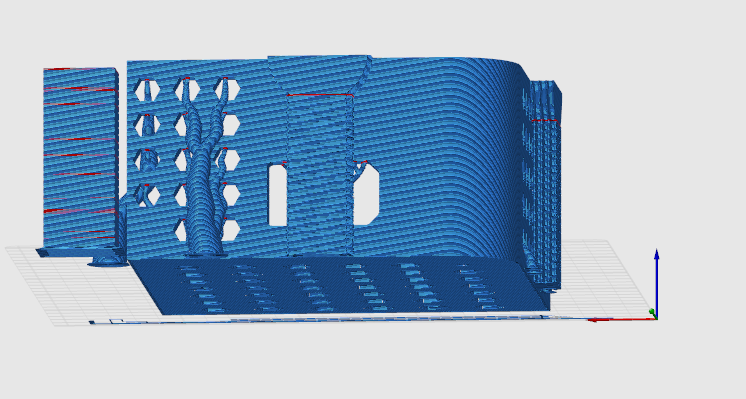

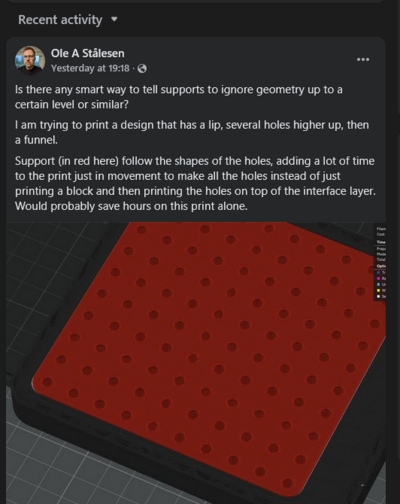

I am also investigating the possibility (I see another guy in bambu studio facebook group asking) of only

This is my model. It does not need the lower supports just the top pf the window and the bottom of the half circles.

this is his question. so I hope to get some suggestions

Onoff

In the land of the unfinished project I am King!

- Messages

- 13,250

- Location

- Sevenoaks, UK

See my post 279:

My lad changed the stock 0.4mm nozzle on the X1C Bambu to a "Hardended Steel vs E3D 0.4mm High Flow ObXidian" (one of his Chrimbo pressies):

Did a couple of "torture" test prints. They go from 15 mm³/s to 35 mm³/s. New nozzle on the left, stock one on the right:

Printed in Bambu Lab PLA Basic Green.

It really puts some volume down and smoothly too!

A cut away of the new nozzle shows how the filament gets "pooled" then extruded through 2 (maybe 3?) channels to massively up the flow rate by something like 60%.

Did a couple of "torture" test prints. They go from 15 mm³/s to 35 mm³/s. New nozzle on the left, stock one on the right:

Printed in Bambu Lab PLA Basic Green.

It really puts some volume down and smoothly too!

A cut away of the new nozzle shows how the filament gets "pooled" then extruded through 2 (maybe 3?) channels to massively up the flow rate by something like 60%.

You seen the price of them now? But they still seem to have no stock. lolSee my post 279:

My lad changed the stock 0.4mm nozzle on the X1C Bambu to a "Hardended Steel vs E3D 0.4mm High Flow ObXidian" (one of his Chrimbo pressies):

Did a couple of "torture" test prints. They go from 15 mm³/s to 35 mm³/s. New nozzle on the left, stock one on the right:

Printed in Bambu Lab PLA Basic Green.

It really puts some volume down and smoothly too!

A cut away of the new nozzle shows how the filament gets "pooled" then extruded through 2 (maybe 3?) channels to massively up the flow rate by something like 60%.

Been having a problem with small holes in the top layer, specifically on parts with lot's of details and lot's of direction changes of the nozzle, anyone have a solution?

Printer is a PrusaXL with a 0,6mm nozzle and the cheapest PLA i could find :-), part in the picture is 10 by 30 mm for scale.

Printer is a PrusaXL with a 0,6mm nozzle and the cheapest PLA i could find :-), part in the picture is 10 by 30 mm for scale.

Dozzer

Forum Supporter

- Messages

- 754

- Location

- Essex/Suffolk border

looks like the 0.6mm nozzle is to big for the size of part your trying to print?Been having a problem with small holes in the top layer, specifically on parts with lot's of details and lot's of direction changes of the nozzle, anyone have a solution?

Printer is a PrusaXL with a 0,6mm nozzle and the cheapest PLA i could find :-), part in the picture is 10 by 30 mm for scale.

the overlap/elephants foot settings may want changing,

Would look at a 0.4 or even a 0.2mm nozzle for very small parts.

daedalusminos

Member

- Messages

- 2,401

- Location

- Norwich

Could you expand a little more or point to a video that shows what you mean with check your result with the slicer?I agree with @Dozzer, nozzle too large. Check your result with the slicer.

Been having a problem with small holes in the top layer, specifically on parts with lot's of details and lot's of direction changes of the nozzle, anyone have a solution?

Printer is a PrusaXL with a 0,6mm nozzle and the cheapest PLA i could find :-), part in the picture is 10 by 30 mm for scale.

have you changed the infill setting? looks weird to me

plus, what % infill are you using?

as above, also looks like you’re not extruding enough

in prusa slicer go to filaments at the top, you can change the "extrusion multiplier"

maybe the cheap filament isn't quick as thick as it's supposed to be, so you're getting less plastic through per m than you should

daedalusminos

Member

- Messages

- 2,401

- Location

- Norwich

This video at 2:40 onwards...Could you expand a little more or point to a video that shows what you mean with check your result with the slicer?

Onoff

In the land of the unfinished project I am King!

- Messages

- 13,250

- Location

- Sevenoaks, UK

@ukracer my lad's musings. He's just off shift and about to crash so just jotted this down as it came to him:

• I've done PETG model with PLA interface and PLA model with PETG interface many times. Works with both a stock 0.4mm nozzle and an after market nozzle. Also mixed multiple brands with no issue.

• You said the filament sometimes failed to retract when changing materials which seems odd and I would expect an error message. Check that the tool head filament cutting blade isn't dull. Check the filament isn't brittle to the point where you can snap it by hand as it could be breaking inside the feed tube. If it does seem brittle this can be solved by drying the filament.

• Regarding supports being in the wrong place. In Bambu Studio you can use the support painting tool to specify where to put supports.

• When printing PLA make sure you keep the door or lid of the printer open to avoid high air temperature and heat creep. The lower the air temperature the better when it comes to PLA. Also make sure the tool head cooling fan is working to prevent heat creep. This is separate from the part cooling fan.

• If filament is getting clogged/jammed make sure they isn't any debris on the filament that is getting pulled into the feed. Perhaps try a 'cold pull' to clean your nozzle.

• Make sure you have enough flushing volume between filament changes to clear the old filament. I normally use around 400mm^3 for multi-material assuming a prime tower is also being used.

• Interface settings. Select 'Bambu Support For PLA/PETG' as your second filament and click yes on the dialouge box to modify support settings. Then change the second filament back to your actual filament. This will ensure no air gap between the layers which is better when using dissimilar supports.

• You could try using a dedicated support filament. Bambu sells some on their website but for me personally PETG/PLA actually works better than the dedicated stuff and its cheaper too.

• The 'glass (something)' you talked about is Glass Transition Temperature. It is the temperature where a filament starts to soften.

If he wants more details on something ask me. i find it crazy he is having so many jam issues on a bambu printer. also if he wants to send me the model or a .3mf save of his slicing setup i can have a look.

• I've done PETG model with PLA interface and PLA model with PETG interface many times. Works with both a stock 0.4mm nozzle and an after market nozzle. Also mixed multiple brands with no issue.

• You said the filament sometimes failed to retract when changing materials which seems odd and I would expect an error message. Check that the tool head filament cutting blade isn't dull. Check the filament isn't brittle to the point where you can snap it by hand as it could be breaking inside the feed tube. If it does seem brittle this can be solved by drying the filament.

• Regarding supports being in the wrong place. In Bambu Studio you can use the support painting tool to specify where to put supports.

• When printing PLA make sure you keep the door or lid of the printer open to avoid high air temperature and heat creep. The lower the air temperature the better when it comes to PLA. Also make sure the tool head cooling fan is working to prevent heat creep. This is separate from the part cooling fan.

• If filament is getting clogged/jammed make sure they isn't any debris on the filament that is getting pulled into the feed. Perhaps try a 'cold pull' to clean your nozzle.

• Make sure you have enough flushing volume between filament changes to clear the old filament. I normally use around 400mm^3 for multi-material assuming a prime tower is also being used.

• Interface settings. Select 'Bambu Support For PLA/PETG' as your second filament and click yes on the dialouge box to modify support settings. Then change the second filament back to your actual filament. This will ensure no air gap between the layers which is better when using dissimilar supports.

• You could try using a dedicated support filament. Bambu sells some on their website but for me personally PETG/PLA actually works better than the dedicated stuff and its cheaper too.

• The 'glass (something)' you talked about is Glass Transition Temperature. It is the temperature where a filament starts to soften.

If he wants more details on something ask me. i find it crazy he is having so many jam issues on a bambu printer. also if he wants to send me the model or a .3mf save of his slicing setup i can have a look.

I shall try these later hopefully. I was informed last night the big grandson., who is back at school tomorrow has 14 tasks he should have done...set by his new school the cheeky buggers. I was only told on Sunday after they went through his rucksack.....@ukracer my lad's settings. He's writing a list of suggestions too:

View attachment 511093

View attachment 511094View attachment 511095

View attachment 511096

I just tried some settings from a makerworld model. PetG to PLA interface. Strangely it failed again. (Thankfully it was a very small model)

This time it failed by some PLA snapping at the hotend. Found about 6 inches in the hotend......very strange.

I cleared it and it carried on printing. But it was not a particularly good print. Contamination it seemed to me. Purge tower was not that large but still a weak model.

Onoff

In the land of the unfinished project I am King!

- Messages

- 13,250

- Location

- Sevenoaks, UK

I shall try these later hopefully.

Email me a .3mf save of the slicer set up and he'll take a look.

Email and attachments sent to your gmail account.Email me a .3mf save of the slicer set up and he'll take a look.

I took delivery of one of the suggested Nozzles yesterday and fitted it last night. For clarity to others following the Thread. the first print came out superb but then again most prints on the X1 do if there are single material. by eye it does seem it might be a bit better but only back to back test will prove that.

I was wondering how the X1 knows I have got a high flow nozzle fitted or if I have to manually adjust it. I am assuming I am supposed to calibrate and set everything up again. I am only using standard speed (Having said that prior to this nozzle, most prints at Sport speed come out just fine)

I am printing boxes as test pieces so I dont waste too much filament but if printed ok they will be useful. This one currently printing is a box for labels on the Brother Ptouch 1000 and although I used PLA as the logo and text filler it is like for like so although some black streaks are evident no weaknes will be present.

This filament prints at a lower temp than normal PLA and I have not had it do stringing before. So I guess the presets I used have changed. This might be why I was getting issues with the PetG models with PLA interface and contamination.

@ukracer my lad's musings. He's just off shift and about to crash so just jotted this down as it came to him:

• I've done PETG model with PLA interface and PLA model with PETG interface many times. Works with both a stock 0.4mm nozzle and an after market nozzle. Also mixed multiple brands with no issue.

I have done quite a few previously.

• You said the filament sometimes failed to retract when changing materials which seems odd and I would expect an error message. Check that the tool head filament cutting blade isn't dull. Check the filament isn't brittle to the point where you can snap it by hand as it could be breaking inside the feed tube. If it does seem brittle this can be solved by drying the filament.

Ah Ah Ah yes its funny you should say that. I am actually printing a Drying tower.

I am doing this mainly as I have had issues with the white PLA snapping in the tubes if I leave it a day or so loading in the printer. So need a decent dryer. But whilst I am aware of whats causing some jams others have been mysterious and not filament breaking in tubes or AMS or Hub.

• Regarding supports being in the wrong place. In Bambu Studio you can use the support painting tool to specify where to put supports.

I was learning about that and one of the files should reflect that learning.

• When printing PLA make sure you keep the door or lid of the printer open to avoid high air temperature and heat creep. The lower the air temperature the better when it comes to PLA.

I have the lid of but also door open as its inside a cupboard.

Also make sure the tool head cooling fan is working to prevent heat creep. This is separate from the part cooling fan.

One thing I had not checked but I am still learning this sdie of things. As you alluded to I should not be getting these jams, and I have not really been getting them until the 4th plate that makes up the base of the dryer.

• If filament is getting clogged/jammed make sure they isn't any debris on the filament that is getting pulled into the feed. Perhaps try a 'cold pull' to clean your nozzle.

I had already tried that thanks though.

• Make sure you have enough flushing volume between filament changes to clear the old filament. I normally use around 400mm^3 for multi-material assuming a prime tower is also being used.

it seems that even 800 or 900 is needed to avoid contamination according to the other guys who have purchased these files.

I will try that . Its a new one on me that.• Interface settings. Select 'Bambu Support For PLA/PETG' as your second filament and click yes on the dialouge box to modify support settings. Then change the second filament back to your actual filament

This will ensure no air gap between the layers which is better when using dissimilar supports.

• You could try using a dedicated support filament. Bambu sells some on their website but for me personally PETG/PLA actually works better than the dedicated stuff and its cheaper too.

I had some with the printer. not even opened it yet as many swear by PLA interface and that its better and cheaper.

This was why I thought the PetG was sticking in the Nozzle. But whilst it was definitely stuck the first time I had issues . But after that I had 3 or 4 breakages in the tubes. even had an inch of filament inside the Hub. lol Not of them were the same but I was operating the printer remotely with my son removing prints (He was working on a car at our house) So I could not see the AMS working etc• The 'glass (something)' you talked about is Glass Transition Temperature. It is the temperature where a filament starts to soften.

If he wants more details on something ask me. i find it crazy he is having so many jam issues on a bambu printer.

Agreed. I have not had many issues. usually this white PLA (which prints great but seems to be affect a lot by damp. I pull a few feet of before loading (or starting if already loaded) . That seems to have helped a great deal.

also if he wants to send me the model or a .3mf save of his slicing setup i can have a look.

Cheers Bud.

Dr.Al

Forum Supporter

- Messages

- 2,750

- Location

- Gloucestershire, UK

Not at all workshop related this one, but my 3D printer made this:

The hinge pin is a bit of 316 TIG welding filler wire

Unfolded:

Folded back on itself as far as it'll go:

"What's that for?" I hear you cry. Well, I've got one of the rather expensive "Quad Lock" phone cases, along with the wallet thing that magnetises onto the back:

Separated:

The little 3D-printed thing (which, when folded up fits easily into a pocket) goes in between the two and turns it into a stand so that I can comfortably read stuff (typically with the Kindle app) with the phone sitting on a table (the phone's been removed just so I could use it to take the photo!):

It can also be used on its own to support the phone in landscape orientation (although I can't remember the last time I wanted to prop my phone up in landscape orientation - if I watch videos I tend to do it on the laptop):

The hinge pin is a bit of 316 TIG welding filler wire

Unfolded:

Folded back on itself as far as it'll go:

"What's that for?" I hear you cry. Well, I've got one of the rather expensive "Quad Lock" phone cases, along with the wallet thing that magnetises onto the back:

Separated:

The little 3D-printed thing (which, when folded up fits easily into a pocket) goes in between the two and turns it into a stand so that I can comfortably read stuff (typically with the Kindle app) with the phone sitting on a table (the phone's been removed just so I could use it to take the photo!):

It can also be used on its own to support the phone in landscape orientation (although I can't remember the last time I wanted to prop my phone up in landscape orientation - if I watch videos I tend to do it on the laptop):