- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tos FN22 milling machine (Deckel clone)

- Thread starter Pete.

- Start date

paradipiro

Member

- Messages

- 109

- Location

- Budapest, Hungary

The angle will be fine, Im around that, but my grit is too coarse.. the grinder is a standard, around 28001/min, with this 180 grit diamond wheel. I could try to hone it ba hand, but im too newbie to even try that.You definitely want the wheel grinding onto the edge, not off it.

I use a 1500 grit flat disc at 400rpm for general scraping. What angle are you using? Try to keep 2-5 degrees negative or so.

The reversing the grinding direcrion definitely helped.

What a rookie mistake, I always grind onto the edge, not from it, but the scraping blade is different, 'cause the money end is on the back side... I havea lot to study!

mtt.tr

Member

- Messages

- 8,138

- Location

- Essex/Suffolk border

I agree with PeteBlade is definitely not sharp enough. It looks like it's skating across the face. The multi-line scratches are where the iron shavings are rolling under the edge of the blade.

How are you sharpening?

Looks like cat scratches

Pete.

Forum Supporter

- Messages

- 15,055

- Location

- Kent, UK

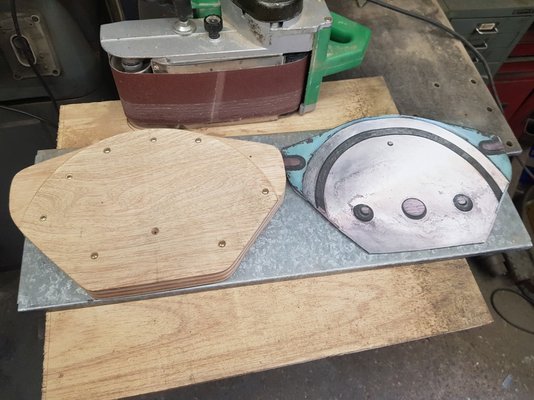

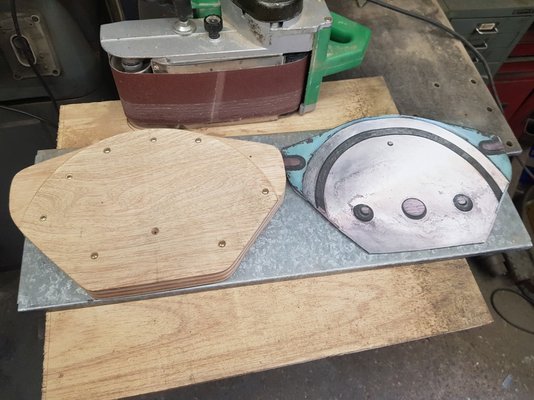

So, I'm looking to get into this machine with a vengeance. Yesterday evening and this evening I've been making a casting pattern for the missing mount plate for the tilting table.

A kind gent sent me these photographs of the plate from his machine:

I tried my best to find this part, or even a full table which found a couple but they were in the Czech Republic and no-one would send one to the UK. So in the end decided there's nothing for it but to make a pattern and have one cast.

I started by printing the pics in 1:1 scale then screwed 3 pieces of 11mm ply together and cut the rough shape with a jig saw

Then I set my router to cut a radius, used a ball end cutter then a square cutter to cut the shallow step in the top

After that I clamped my belt sander to the bench and used it to sand the outside profile at a draft angle

A quick sand over and things are looking good for the top

A kind gent sent me these photographs of the plate from his machine:

I tried my best to find this part, or even a full table which found a couple but they were in the Czech Republic and no-one would send one to the UK. So in the end decided there's nothing for it but to make a pattern and have one cast.

I started by printing the pics in 1:1 scale then screwed 3 pieces of 11mm ply together and cut the rough shape with a jig saw

Then I set my router to cut a radius, used a ball end cutter then a square cutter to cut the shallow step in the top

After that I clamped my belt sander to the bench and used it to sand the outside profile at a draft angle

A quick sand over and things are looking good for the top

Pete.

Forum Supporter

- Messages

- 15,055

- Location

- Kent, UK

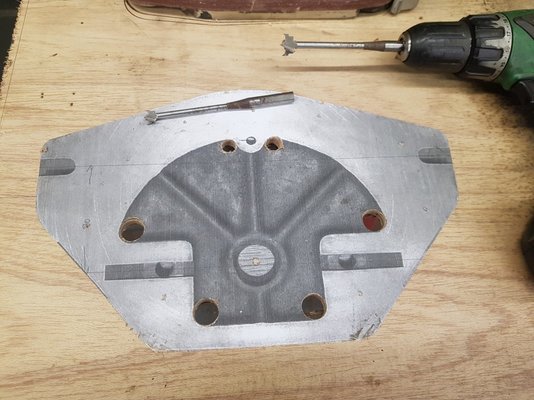

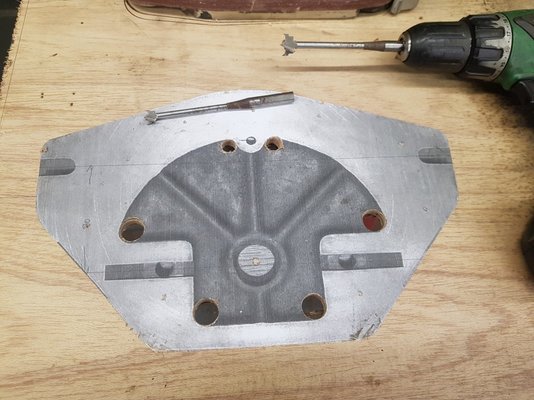

Now for the underside hollow cored out section. I glued a pattern to some scrap plywood, drilled the corner holes and cut the shape out with a jigsaw to make a template.

Then I split out the pattern into 3 layers and fixed the bottom layer to my template. Cut the shape out with my router.

Re-assembled the pattern and it's looking pretty good

I put the knuckle on the pattern to check the fit and it's pretty good too.

Glued the piece I 3-d printed over a year ago to the underside to form the stiffener webs, then used body filler to create the inside drafts.

That's it for now, got to finsh filling then put a load of paint on it later.

Then I split out the pattern into 3 layers and fixed the bottom layer to my template. Cut the shape out with my router.

Re-assembled the pattern and it's looking pretty good

I put the knuckle on the pattern to check the fit and it's pretty good too.

Glued the piece I 3-d printed over a year ago to the underside to form the stiffener webs, then used body filler to create the inside drafts.

That's it for now, got to finsh filling then put a load of paint on it later.

pressbrake1

Member

- Messages

- 5,553

- Location

- Essex

Don’t forget shrinkage!

Pete.

Forum Supporter

- Messages

- 15,055

- Location

- Kent, UK

Don’t forget shrinkage!

I got about 2mm extra around the rim of the knuckle, with the facility to perhaps move it back another couple if the shrinkage is too great..

Pete.

Forum Supporter

- Messages

- 15,055

- Location

- Kent, UK

Great to see you're back on this @Pete. Looking forward to future posts.

Thanks, they'll be coming rest assured. I'm determned to get this thing rebuilt now. The past year and a half have been rough with personal things putting life on hold and a massive dismantling job that took a whole year to cut up nearly 2000 tonnes of concrete but things seem to be settling down now.

Pete.

Forum Supporter

- Messages

- 15,055

- Location

- Kent, UK

Well I can buy a complete good condition tilting table in the Czech Republic for about £400 plus shipping but I cannot find anyone who will ship one to the UK and I doubt that this one piece will end up much cheaper if any at all when it's been cast, heat treated, planed/ground then the slot machined.

Given the choice I would prefer to just buy the entire thing but I just can't find a way.

Given the choice I would prefer to just buy the entire thing but I just can't find a way.

pressbrake1

Member

- Messages

- 5,553

- Location

- Essex

I’m sorting it for Pete and putting it in with one of my orders so hopefully £150Great work on the cast mould!

I am interested to know what that part will cost to get cast.

I am also pretty interested to know how much it generally cost to get one off parts casted in the UK.

Get it in a small crate or on a pallet we can ship it no problem. We are customs agents as well these days which helps.80KG - no I hadn't

Pete.

Forum Supporter

- Messages

- 15,055

- Location

- Kent, UK

Get it in a small crate or on a pallet we can ship it no problem. We are customs agents as well these days which helps.

My problem isn't shipping mate, it's getting the seller to be willing to ship.

Pete.

Forum Supporter

- Messages

- 15,055

- Location

- Kent, UK

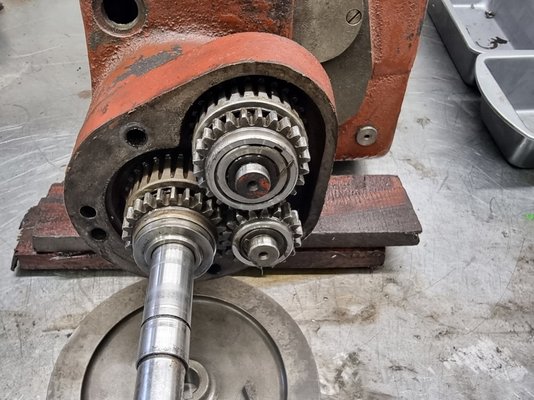

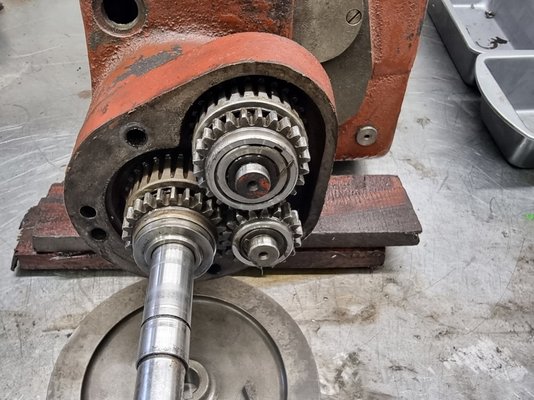

OK so I found out why some other machines have a little control knob on the gearbox and others don't. The control knob is a reversing control for those rare times when you might need to run the mill in reverse, it allows the feed gearbox to turn the correct way with the motor running backwards.

This machine has a nifty double sprag clutch system where one clutch works directly on the gearbox and the other is driven through an idler gear so it does it all automatically. Turning the input pulley anti-clockwise causes the lower sprag to drive and the idler-driven upper sprag to slip and the gearbox input turns anti-clockwise. Turning it clockwise causes the lower sprag to slip and the upper sprag to drive but because of the idler in the train the input shaft still turns anti-clockwise.

I have to replace the rollers and needles in one section of this because they are worn out from constantly idling (and low oil level). Oh, and if you're reading this and considering taking this lot apart - clean your bench and floor first because the needles and rollers fly out everywhere.

This machine has a nifty double sprag clutch system where one clutch works directly on the gearbox and the other is driven through an idler gear so it does it all automatically. Turning the input pulley anti-clockwise causes the lower sprag to drive and the idler-driven upper sprag to slip and the gearbox input turns anti-clockwise. Turning it clockwise causes the lower sprag to slip and the upper sprag to drive but because of the idler in the train the input shaft still turns anti-clockwise.

I have to replace the rollers and needles in one section of this because they are worn out from constantly idling (and low oil level). Oh, and if you're reading this and considering taking this lot apart - clean your bench and floor first because the needles and rollers fly out everywhere.

Hopefuldave

Intergalactic pot-mender

- Messages

- 2,492

- Location

- The Shed of Danger, surrey, England

Ah, not just pingfeckits, expensive pingfeckits! The vacuum bags for shrinking clothes are handy, dismantle inside one to trap the PFs when they make their desperate bid for freedom... they can even be gagger taped - oops, GAFFER taped (Freudian slip there) in place when driving complicated parts out.OK so I found out why some other machines have a little control knob on the gearbox and others don't. The control knob is a reversing control for those rare times when you might need to run the mill in reverse, it allows the feed gearbox to turn the correct way with the motor running backwards.

View attachment 412819

This machine has a nifty double sprag clutch system where one clutch works directly on the gearbox and the other is driven through an idler gear so it does it all automatically. Turning the input pulley anti-clockwise causes the lower sprag to drive and the idler-driven upper sprag to slip and the gearbox input turns anti-clockwise. Turning it clockwise causes the lower sprag to slip and the upper sprag to drive but because of the idler in the train the input shaft still turns anti-clockwise.

View attachment 412818

View attachment 412815

View attachment 412816

View attachment 412817

I have to replace the rollers and needles in one section of this because they are worn out from constantly idling (and low oil level). Oh, and if you're reading this and considering taking this lot apart - clean your bench and floor first because the needles and rollers fly out everywhere.