You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Small Diesel Shop Heater

- Thread starter R Kraft

- Start date

Yet you still installed your's not in accordance to said manual, as you 'know better'?RTFM ' ing several times is also helpful to dispel might's and guesses though some folk think they know better .

Scalarocco

Smile, or I'll bite your leg...

- Messages

- 485

- Location

- Rossendale

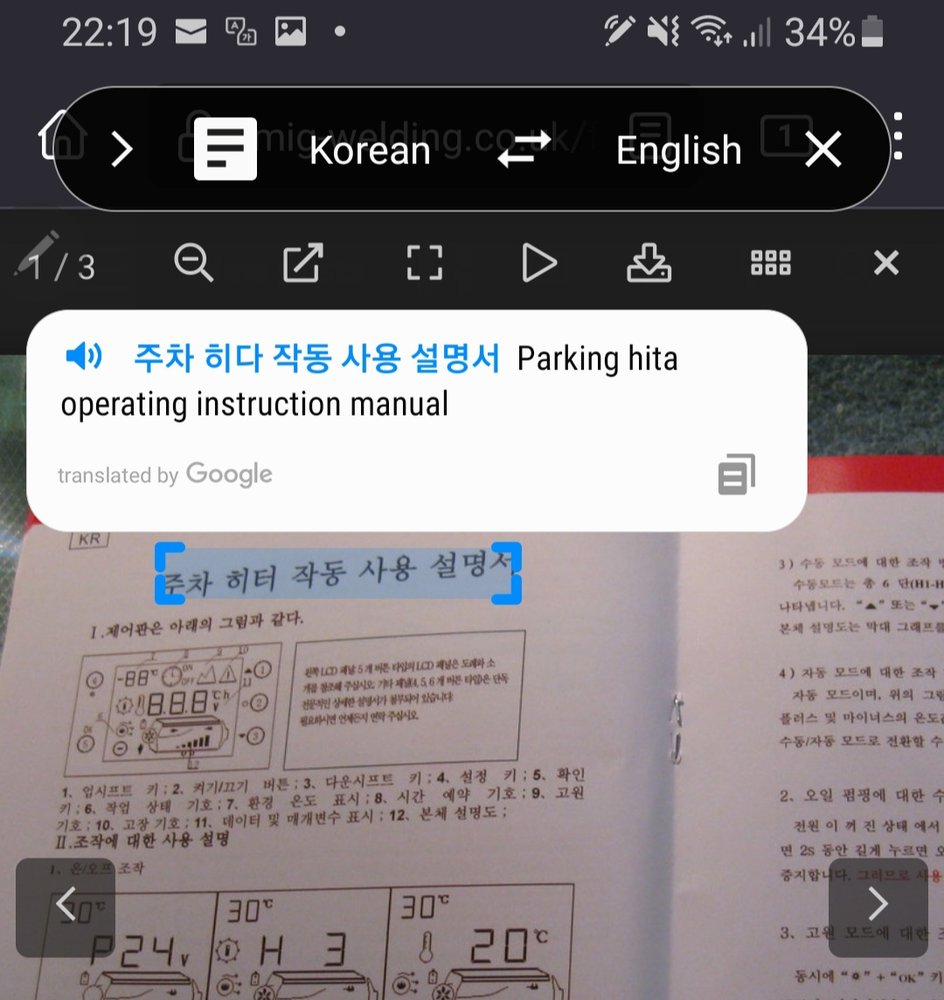

Looks like you need to brush up on your Korean.

Any exposed exhaust pipe gets far hotter than the body casing where the heated air passes, so unless you have the heater fitted so there is no exhaust pipe inside your workshop, there is little additional, if any benefit to drawing in external air for heating.

JOEPRO

Member

- Messages

- 5,285

- Location

- UK

I will be installing mine now when it arrives in a week or so all being well.

Exhaust taken to outside through wall.

Air intake hose and filter inside.

C02 Alarm inside the Garage.

Simples. I'm not going to be preheating the cold outside air, my garage has plenty of draughts coming in already! If my garage is 20c inside temp as some people are indicating could lead to an overheat scenario don't worry because:

A: my garage floor air will never be ay 20c or near it. More like 5 - 10c when using the heater.

B: IF the internal air temp is near 20c the heater won't be on in the first instance!

I will be addressing a couple of the main draughts though. 100mm insulation laid over the garage attic hatch and new carpet offcuts to form a draught barrier on top of my roller shutter door which is about 14 feet wide and has a good 2 - 3 inch gap along the top.

Exhaust taken to outside through wall.

Air intake hose and filter inside.

C02 Alarm inside the Garage.

Simples. I'm not going to be preheating the cold outside air, my garage has plenty of draughts coming in already! If my garage is 20c inside temp as some people are indicating could lead to an overheat scenario don't worry because:

A: my garage floor air will never be ay 20c or near it. More like 5 - 10c when using the heater.

B: IF the internal air temp is near 20c the heater won't be on in the first instance!

I will be addressing a couple of the main draughts though. 100mm insulation laid over the garage attic hatch and new carpet offcuts to form a draught barrier on top of my roller shutter door which is about 14 feet wide and has a good 2 - 3 inch gap along the top.

RIP

Kairo

- Messages

- 3,030

- Location

- Netherlands

Good point on the solvents, got to be careful with that. I put my heaters inside because it seemed simpler and I didn't know much about them at the time. Mine draw air from inside as there's limited space to drill more holes due for an air intake, but I could change that.

I was also cautious about the fuel lines near the hot exhaust. The exhaust gets to 190C IIRC, the best fuel lines I've seen are rated to 120C, some only to 80C. I used heat protective sleeving, as used to protect wires inside ovens, to cover the fuel lines. For the lines themselves I used the original Chinese green Silica gel lines on one heater and what looks like a Tygon copycat line on the other. There's a lot of fuel lines being sold on ebay that are plain dangerous. There's one eBayer selling plain aquarium hose as fuel hose, I fell for it, the line hardened within 4 weeks and failed. Be careful. In hindsight I would probably go for the semi rigid (nylon?) line sold specially for these heaters, and still put the heater protection sleeve over it.

I've watched all of John's YouTube videos, very interesting.

I was also cautious about the fuel lines near the hot exhaust. The exhaust gets to 190C IIRC, the best fuel lines I've seen are rated to 120C, some only to 80C. I used heat protective sleeving, as used to protect wires inside ovens, to cover the fuel lines. For the lines themselves I used the original Chinese green Silica gel lines on one heater and what looks like a Tygon copycat line on the other. There's a lot of fuel lines being sold on ebay that are plain dangerous. There's one eBayer selling plain aquarium hose as fuel hose, I fell for it, the line hardened within 4 weeks and failed. Be careful. In hindsight I would probably go for the semi rigid (nylon?) line sold specially for these heaters, and still put the heater protection sleeve over it.

I've watched all of John's YouTube videos, very interesting.

James1979

Member

- Messages

- 8,290

- Location

- Orkney

I tend to use the hard cunifer style pipe if it’s needed. You can get compression fittings etc to suit.Good point on the solvents, got to be careful with that. I put my heaters inside because it seemed simpler and I didn't know much about them at the time. Mine draw air from inside as there's limited space to drill more holes due for an air intake, but I could change that.

I was also cautious about the fuel lines near the hot exhaust. The exhaust gets to 190C IIRC, the best fuel lines I've seen are rated to 120C, some only to 80C. I used heat protective sleeving, as used to protect wires inside ovens, to cover the fuel lines. For the lines themselves I used the original Chinese green Silica gel lines on one heater and what looks like a Tygon copycat line on the other. There's a lot of fuel lines being sold on ebay that are plain dangerous. There's one eBayer selling plain aquarium hose as fuel hose, I fell for it, the line hardened within 4 weeks and failed. Be careful. In hindsight I would probably go for the semi rigid (nylon?) line sold specially for these heaters, and still put the heater protection sleeve over it.

I've watched all of John's YouTube videos, very interesting.

Mandatory in boats for some MCA code. Also on Norfolk Broads, randomly.

I’ve used it where I’m not happy about the plastic stuff being.

That’s a lot but you can get the bits separately. I think plumb base do 4mm.

RIP

Kairo

- Messages

- 3,030

- Location

- Netherlands

I thought about copper, but I couldn't figure out how I'll attach the copper to the heater fuel input as it has a barb/bulge, or even if I could, whether that's a good idea considering the heater may move or vibrate a bit relative to the wall mounted copper line.I tend to use the hard cunifer style pipe if it’s needed. You can get compression fittings etc to suit.

Mandatory in boats for some MCA code. Also on Norfolk Broads, randomly.

I’ve used it where I’m not happy about the plastic stuff being.

That’s a lot but you can get the bits separately. I think plumb base do 4mm.

James1979

Member

- Messages

- 8,290

- Location

- Orkney

2 ways. Either use a rubber hose joiner like you would with the plastic pipe, or use a compression fitting.I thought about copper, but I couldn't figure out how I'll attach the copper to the heater fuel input as it has a barb/bulge, or even if I could, whether that's a good idea considering the heater may move or vibrate a bit relative to the wall mounted copper line.

You may need to cut the ‘bellend’ off the input. Use a “bite olive”, normally used for gas.

I’ve done that many times and not had a leak. The vibrations between the two is negligible if it’s installed well.

Mount the pipe on p clips to insulate it further from movement.

Haven’t cut that input but just to show you it goes straight on.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

Final page of the Korean manual , top couple of lines gives some guidance of what not to do & what to do .Any exposed exhaust pipe gets far hotter than the body casing where the heated air passes, so unless you have the heater fitted so there is no exhaust pipe inside your workshop, there is little additional, if any benefit to drawing in external air for heating.

Prajna

Fixing things for the love of it

- Messages

- 683

- Location

- Castelo Branco, Portugal

I wouldn't worry too much about 20° input air. John's testing was mostly on warm Aussi days where the ambient temperature was above that. He was concerned that on boost the heater was close to its overheat temperature but it didn't hit the shutdown temperature on short runs at boost. Eber specifies max 40°C input temperature but doesn't say whether that limit applies when running at boost or on a lower setting. It is probably worth being aware of but not a critical limit.I will be installing mine now when it arrives in a week or so all being well.

Exhaust taken to outside through wall.

Air intake hose and filter inside.

C02 Alarm inside the Garage.

Simples. I'm not going to be preheating the cold outside air, my garage has plenty of draughts coming in already! If my garage is 20c inside temp as some people are indicating could lead to an overheat scenario don't worry because:

A: my garage floor air will never be ay 20c or near it. More like 5 - 10c when using the heater.

B: IF the internal air temp is near 20c the heater won't be on in the first instance!

I will be addressing a couple of the main draughts though. 100mm insulation laid over the garage attic hatch and new carpet offcuts to form a draught barrier on top of my roller shutter door which is about 14 feet wide and has a good 2 - 3 inch gap along the top.

RIP

Kairo

- Messages

- 3,030

- Location

- Netherlands

Nice2 ways. Either use a rubber hose joiner like you would with the plastic pipe, or use a compression fitting.

You may need to cut the ‘bellend’ off the input. Use a “bite olive”, normally used for gas.

I’ve done that many times and not had a leak. The vibrations between the two is negligible if it’s installed well.

Mount the pipe on p clips to insulate it further from movement.

View attachment 388178

View attachment 388179

Haven’t cut that input but just to show you it goes straight on.

I'll keep an eye on my fuel lines to see if the Chinese Silica Gel and Tygon knockoff line lasts. If not then copper it is. I'm also planning to wrap the wiring in something in case any angle grinder sparks land on it.

I'll keep an eye on my fuel lines to see if the Chinese Silica Gel and Tygon knockoff line lasts. If not then copper it is. I'm also planning to wrap the wiring in something in case any angle grinder sparks land on it.DAPPH would you fill us in on what the Korean manual says, as different heaters have different manuals, and I'm not sure what bit you say we've missed.Final page of the Korean manual , top couple of lines gives some guidance of what not to do & what to do .

Last edited:

Surely you are using a CO alarm and not a CO2 one?I will be installing mine now when it arrives in a week or so all being well.

Exhaust taken to outside through wall.

Air intake hose and filter inside.

C02 Alarm inside the Garage.

Simples. I'm not going to be preheating the cold outside air, my garage has plenty of draughts coming in already! If my garage is 20c inside temp as some people are indicating could lead to an overheat scenario don't worry because:

A: my garage floor air will never be ay 20c or near it. More like 5 - 10c when using the heater.

B: IF the internal air temp is near 20c the heater won't be on in the first instance!

I will be addressing a couple of the main draughts though. 100mm insulation laid over the garage attic hatch and new carpet offcuts to form a draught barrier on top of my roller shutter door which is about 14 feet wide and has a good 2 - 3 inch gap along the top.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

Make or get someone to turn up a compression adaptor & soft copper olives & cut off the bulbous bulgeI thought about copper, but I couldn't figure out how I'll attach the copper to the heater fuel input as it has a barb/bulge, or even if I could, whether that's a good idea considering the heater may move or vibrate a bit relative to the wall mounted copper line.

I didn't bother ...... I've just used the translucent white opaque fuel line tube that came with the kit .

Whilst the surface of the exhaust outlet point will be around 190 oC a few mm away the temp drops considerably .... measure the temp at the plastic fuel line & not covering exhaust radiance is perhaps the easier way to go . I simply held my fingers on the joint where the fuel line goes into the burner ...

it's hot.

it's hot.The self contained models mean you can't recirculate the heated air if the unit is outside. Unless you cut the grill out at the back.Been browsing this thread. Can someone tell me if I'm understanding this right in terms of what intake is what on this heater:

View attachment 388163

Reading this thread got me a little worried, as I'm constantly using solvents in the workshop with the heater on (thinners, brake cleaner, acetone, iso), and it looks like I'm drawing air from inside. But on my heater (shown above) there is no flange to put a pipe on what I assume to be the intake for heating air? I have the combustion air intake and combustion exhaust going outside pointing in different directions, never had an issue with that.

One of mine draws in cold air from outside and the other recirculates the warm heating air. Doesn't seem to be much difference in efficiency but there must be.

I don't use mine in the prescence of solvents but it makes sense to keep them apart.

Been using this type of heater for 3 years now they are brilliant.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

Use google translate, Title for my manual isNiceI'll keep an eye on my fuel lines to see if the Chinese Silica Gel and Tygon knockoff line lasts. If not them copper it is. I'm also planning to wrap the wiring in something in case any angle grinder sparks land on them.

DAPPH would you fill us in on what the Korean manual says, as different heaters have different manuals, and I'm not sure what bit you say we've missed.

AIR HEATER KW 2.0 5.0 8.0 manual

The code of use and installation guidance were what I used to set mine up , there was a single side sheet of printed stuff that gave a few more installation tips & a packing list of contents of the package . Might still be out inthe mancupoboard .

First sentence of the code of use ( 1.) says it all really wrt safety . With the exception of when using subzero fuel at minus 11 oC or so to refill the fuel tank don't spill any on yourself or clothing as it will seriously cold burn you .

finyuk2005

Member

- Messages

- 860

i just used copper/kuniper brake line, and put a slight flare on the ends with a brake flaring tool, then just used rubber fuel hose and decent hose clamps to secure it allI thought about copper, but I couldn't figure out how I'll attach the copper to the heater fuel input as it has a barb/bulge, or even if I could, whether that's a good idea considering the heater may move or vibrate a bit relative to the wall mounted copper line.

James1979

Member

- Messages

- 8,290

- Location

- Orkney

How much something?NiceI'll keep an eye on my fuel lines to see if the Chinese Silica Gel and Tygon knockoff line lasts. If not then copper it is. I'm also planning to wrap the wiring in something in case any angle grinder sparks land on it.

DAPPH would you fill us in on what the Korean manual says, as different heaters have different manuals, and I'm not sure what bit you say we've missed.

I’ve got miles of exhaust bandage.

Could chuck a couple of metres in the post?

RIP

Kairo

- Messages

- 3,030

- Location

- Netherlands

I was indeed thinking of exhaust wrap. I'll PM you. I currently have a fairly chunky 1m long wiring harness running up the wall from the heaters to a key cabinet above that hides the pumps, controllers, and power supply. I identified the stock CDH connectors as Furukawa motorcycle connectors, bought some cheap on Ali Express, and made custom extensions. This way if a heater fails I can easily swap it out with a new one without need to splice wires or anything like that, just plug in and go. The worry I have with this setup is that now the pumps are above the heaters which seems to contravene the manual. So far it's working though, but with the warm weather I haven't run the heaters extensively enough to be sure that the lines won't fill up with air.How much something?

I’ve got miles of exhaust bandage.

Could chuck a couple of metres in the post?

Last edited:

WHERE ?

WHERE ?