Kram

Member

- Messages

- 8,404

- Location

- Sussex

Interesting, what DoC would you use?

) and 500-2200 rpm. Depends on material some prefer a fast feed. By hand, so far from being consistent but I can say it is painfully slow on any longer parts.

) and 500-2200 rpm. Depends on material some prefer a fast feed. By hand, so far from being consistent but I can say it is painfully slow on any longer parts.

Its a rough guess based on a 0.2mm division of the wheel per second (or, a kram-second, may have a vastly different length to a real secondYou being serious, 0.005mm/rev?

) and 500-2200 rpm. Depends on material some prefer a fast feed. By hand, so far from being consistent but I can say it is painfully slow on any longer parts.

) and 500-2200 rpm. Depends on material some prefer a fast feed. By hand, so far from being consistent but I can say it is painfully slow on any longer parts.

First couple of passes went fine, but then instead of cutting properly, the tool would luch forward in the backlash, wait for the leadscrew to catch up with the nut and then chew a really nasty thread into the rest of the part, eventually getting to the point that it cut the crest off the partially formed thread and I gave up. Took me a couple of days to realise what I'd done wrong.

First couple of passes went fine, but then instead of cutting properly, the tool would luch forward in the backlash, wait for the leadscrew to catch up with the nut and then chew a really nasty thread into the rest of the part, eventually getting to the point that it cut the crest off the partially formed thread and I gave up. Took me a couple of days to realise what I'd done wrong.

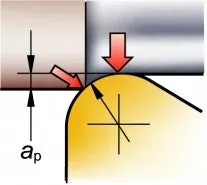

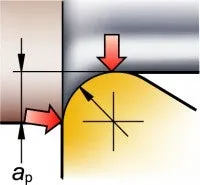

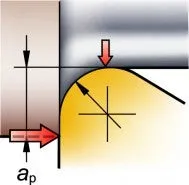

, Good rule of thumb and easy to remember about the radius and DOC .

, Good rule of thumb and easy to remember about the radius and DOC . , I like the easy of use of carbide aswell as the mirror finish can almost impossible to get from HHS i understand however it can create really smooth finishes just not mirror which I want because erm it looks nice lol

, I like the easy of use of carbide aswell as the mirror finish can almost impossible to get from HHS i understand however it can create really smooth finishes just not mirror which I want because erm it looks nice lol