- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Machining Techniques and Materials

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you machining?

- Thread starter Kram

- Start date

Agroshield

Member

- Messages

- 6,341

...struggled to find the thread details in my Zeus book...

Try here:

lchris21

Member

- Messages

- 2,014

- Location

- South Wales

well well well.............every day is a school day!..............I used my eyecrometer in the end. Cheers

dan.taylor.1

General Tinkererer

- Messages

- 2,750

- Location

- Kendal, Cumbria

They've messed up Whitworth and bsf/bsc/bsp on there though...

Agroshield

Member

- Messages

- 6,341

They've messed up Whitworth and bsf/bsc/bsp on there though...

I have to ask please what you have seen that is incorrect as I could not see anything obvious on BSW and BSF (near the bottom of the page in green). They have the wrong imperial major dia. on BSPP (but correct metric major dia.). Also, I could not see BSC at all (normally denoted BSCy and 60 degree thread angle).

dan.taylor.1

General Tinkererer

- Messages

- 2,750

- Location

- Kendal, Cumbria

Just the naming, like that they've called bsf (British standard fine) Whitworth fine and bspt Whitworth pipe tapered, I know most bs threads are derived from Whitworth but I've never seen bspt referred to as a Whitworth thread.I have to ask please what you have seen that is incorrect as I could not see anything obvious on BSW and BSF (near the bottom of the page in green). They have the wrong imperial major dia. on BSPP (but correct metric major dia.). Also, I could not see BSC at all (normally denoted BSCy and 60 degree thread angle).

dan.taylor.1

General Tinkererer

- Messages

- 2,750

- Location

- Kendal, Cumbria

And I mean British standard coarse by BSC is this not the correct acronym?

Agroshield

Member

- Messages

- 6,341

Just the naming... ...and I mean British standard coarse by BSC is this not the correct acronym?

Thanks. I was concerned there was something wrong with the numbers. As the site is German, we can perhaps allow them a little slack on the nomenclature.

Initially, when Joe Whitworth standardised the threads, there was no fine series, so there was no need to call them coarse. They were just BSW or British Standard Whitworth. Later, when the fine series was standardised, it was named BSF, British Standard Fine to distinguish it from BSW. It is very similar to the way metric threads are designated - you have ISO metric, which is the standard coarse series and then metric fine.

Sorry I misunderstood your abbreviation. There is yet another obscure British thread, called British Standard Cycle or BSCy. This was used on bicycles and early motorbikes. It has imperial dimensions, is a fine thread for its diameter and is 60 degree vee-angle. I have now found BSCy on the site above, it is under CEI thread (https://www.gewinde-normen.de/en/cei-thread.html). BSCy is sometimes hard to distinguish from BSB, British Standard Brass, which has a number of identical or shared diameter/pitch combinations but is 55 degree vee-angle.

dan.taylor.1

General Tinkererer

- Messages

- 2,750

- Location

- Kendal, Cumbria

Yeah I'm aware of the cycle thread, had to repair a few when I was a bike tech as my first job. Every day is a school day, my grandad says if you don't learn something new every day you weren't paying attention.

Lewis_RX8

Member

- Messages

- 1,556

- Location

- Scotland

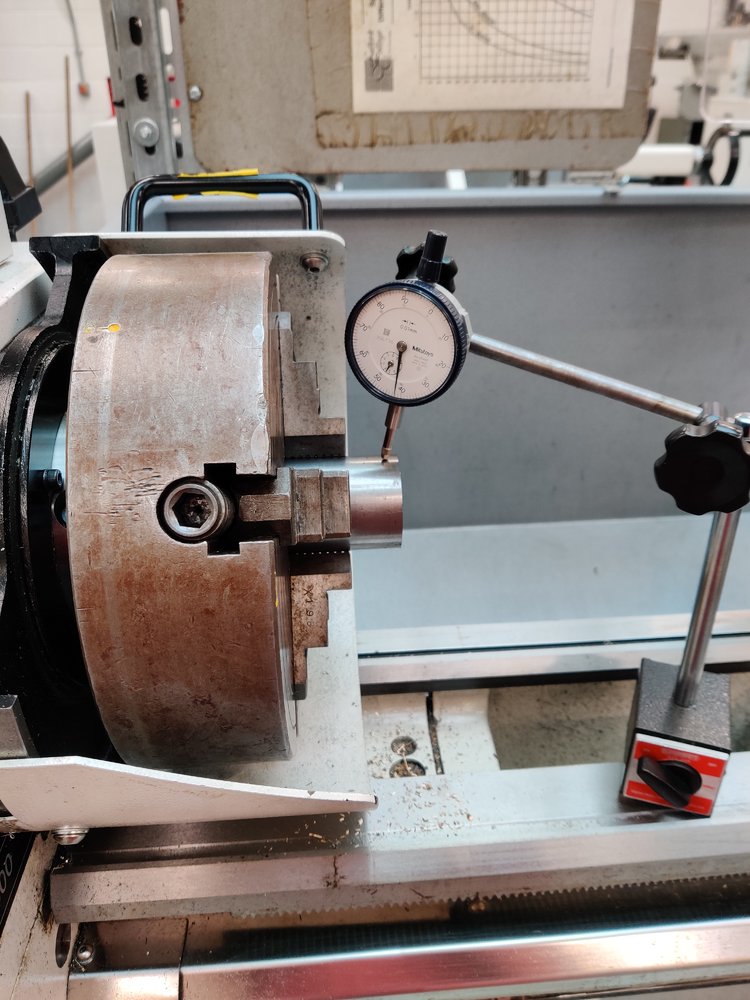

Making a die holder at the moment for a training piece

The lecturer liked my two nuts together trick for how to sharpen drill bits that works on big or small ones just as good

Still getting better at the sharpening as I go but Intresting doing it on 24mm drills not the 10mm or so I'm used to doing

The lecturer liked my two nuts together trick for how to sharpen drill bits that works on big or small ones just as good

Still getting better at the sharpening as I go but Intresting doing it on 24mm drills not the 10mm or so I'm used to doing

Lewis_RX8

Member

- Messages

- 1,556

- Location

- Scotland

Wrote out a nice message here but refreshed and deleted it bugger

Bit of playings on the training lathe not my own , trying to achieve a nice finish with the inserts and tool we had. First tried the manufacture recommended speeds and feeds however these where the quite fast and hard which did get a nice mirror shine off the cut however was a lot of grooves and deep lines chatter and stuff as not sure if these lathes 2hp and not very rigid can really handle that may have been some slop somewhere did try tightening gibs but not a huge help.

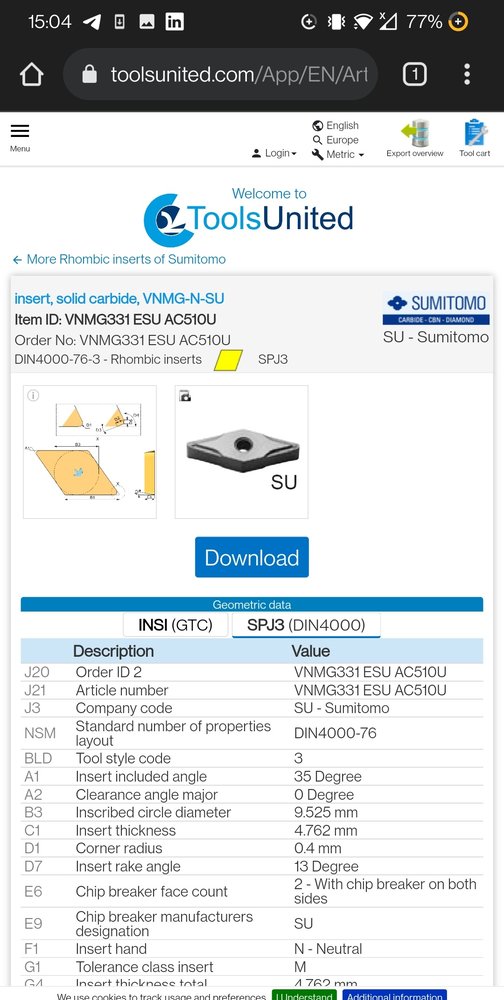

Then a mate recommended the complete opposite low feed and low speed thought hmm that seems like it'll work even less but worked quite well IMO , insert spec sheet shown and it was set at

80 then 180 RPM same finish

0.001 inch per rev / 0.03 mm per rev feed

Coolant flood

Only thing is with those speeds / feeds its a boring job lol sitting there waiting for it to travel across only good for final finishing dimension cuts but also works well for that as can tickle off a few thou easily and still produce a good finish rather than being stuck with needing to take a bigger DOC for proper carbide speeds / feeds

Camera makes the finish look worse I think picks up all the lines but really impressed with finish really smooth doesn't catch fingernail and can see reflections in it

Bit of playings on the training lathe not my own , trying to achieve a nice finish with the inserts and tool we had. First tried the manufacture recommended speeds and feeds however these where the quite fast and hard which did get a nice mirror shine off the cut however was a lot of grooves and deep lines chatter and stuff as not sure if these lathes 2hp and not very rigid can really handle that may have been some slop somewhere did try tightening gibs but not a huge help.

Then a mate recommended the complete opposite low feed and low speed thought hmm that seems like it'll work even less but worked quite well IMO , insert spec sheet shown and it was set at

80 then 180 RPM same finish

0.001 inch per rev / 0.03 mm per rev feed

Coolant flood

Only thing is with those speeds / feeds its a boring job lol sitting there waiting for it to travel across only good for final finishing dimension cuts but also works well for that as can tickle off a few thou easily and still produce a good finish rather than being stuck with needing to take a bigger DOC for proper carbide speeds / feeds

Camera makes the finish look worse I think picks up all the lines but really impressed with finish really smooth doesn't catch fingernail and can see reflections in it

Time to get those tools I linked to.Wrote out a nice message here but refreshed and deleted it bugger

Bit of playings on the training lathe not my own , trying to achieve a nice finish with the inserts and tool we had. First tried the manufacture recommended speeds and feeds however these where the quite fast and hard which did get a nice mirror shine off the cut however was a lot of grooves and deep lines chatter and stuff as not sure if these lathes 2hp and not very rigid can really handle that may have been some slop somewhere did try tightening gibs but not a huge help.

Then a mate recommended the complete opposite low feed and low speed thought hmm that seems like it'll work even less but worked quite well IMO , insert spec sheet shown and it was set at

80 then 180 RPM same finish

0.001 inch per rev / 0.03 mm per rev feed

Coolant flood

Only thing is with those speeds / feeds its a boring job lol sitting there waiting for it to travel across only good for final finishing dimension cuts but also works well for that as can tickle off a few thou easily and still produce a good finish rather than being stuck with needing to take a bigger DOC for proper carbide speeds / feeds

View attachment 319394View attachment 319393View attachment 319395

Camera makes the finish look worse I think picks up all the lines but really impressed with finish really smooth doesn't catch fingernail and can see reflections in it

View attachment 319397View attachment 319396

Yesterday though I was just turning down a bar to act as a spacer. In a bit of a rush pushed the old Triumph a lot harder. Seriously deep cut could actually hear the lathe working. The swarf flying off was golden brown and smoking - best finish I have ever had with a cnmg or whatever they are called

For normal use though I prefer those sharp aluminium cutting tips.

Lewis_RX8

Member

- Messages

- 1,556

- Location

- Scotland

Yup those tips really need pushed on a ridgid powerful lathe to get a good finish I think , not sure how the YouTubers make it look so easy lolTime to get those tools I linked to.

Yesterday though I was just turning down a bar to act as a spacer. In a bit of a rush pushed the old Triumph a lot harder. Seriously deep cut could actually hear the lathe working. The swarf flying off was golden brown and smoking - best finish I have ever had with a cnmg or whatever they are called

For normal use though I prefer those sharp aluminium cutting tips.

Yes ground / polished inserts for aluminium is the next try

If you don't have to jump out of the way now and again you're not trying @fizzyTime to get those tools I linked to.

Yesterday though I was just turning down a bar to act as a spacer. In a bit of a rush pushed the old Triumph a lot harder. Seriously deep cut could actually hear the lathe working. The swarf flying off was golden brown and smoking - best finish I have ever had with a cnmg or whatever they are called

For normal use though I prefer those sharp aluminium cutting tips.

You are right there only baby cuts in the past.If you don't have to jump out of the way now and again you're not trying @fizzy

............struggled to find the thread details in my Zeus book

............struggled to find the thread details in my Zeus book