Munkul

Jack of some trades, Master of none

- Messages

- 7,747

- Location

- Cumbria

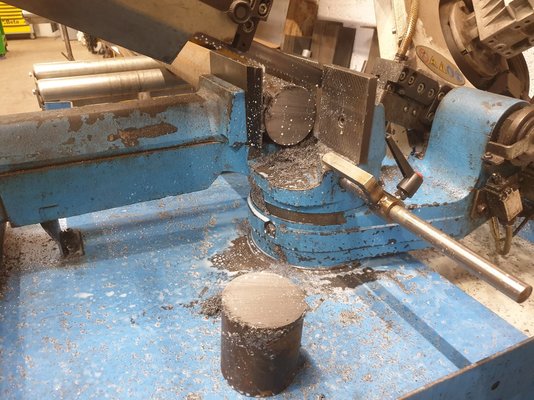

The kennametal inserts and blade I use need next to no cutting pressure, they just glide through stuff. I even parted off an alloy steel impact chisel one time. Gets a bit tougher as they reach the centre and the surface speed is slow.

Right enough the iscar tang grip blades at work are well liked by both machinists, one of them is too scared to push them hard too. That's on a DSG 17 and harrison M450.

Probably like you say it comes down to mass and rigidity. 120kg is very light... barely heavier than a myford! I'm impressed that you're managing to use a 25mm drill in it

Right enough the iscar tang grip blades at work are well liked by both machinists, one of them is too scared to push them hard too. That's on a DSG 17 and harrison M450.

Probably like you say it comes down to mass and rigidity. 120kg is very light... barely heavier than a myford! I'm impressed that you're managing to use a 25mm drill in it

I like that you bottom out the insert on 3 sides on the A2 blade, rather than 2 sides like most parting insert designs.

I like that you bottom out the insert on 3 sides on the A2 blade, rather than 2 sides like most parting insert designs.