You are either a sadist or you do not do much cast.

I used to do a lot of hauler plates on the manual lathe and had to wear welding gauntlets whilst cutting the face tapers with the compound slide. Now I do them on the CNC and the worst part is cleaning up afterwards as cast iron is not the best for a lathe and also will set like concrete if flood coolant is used and it is not cleaned up right away.

This is the small ones I do, 13" , most now are bigger, 17" and 19"

I have only ever machined nice high quality free cutting cast iron.

And I thought it should always be done dry?

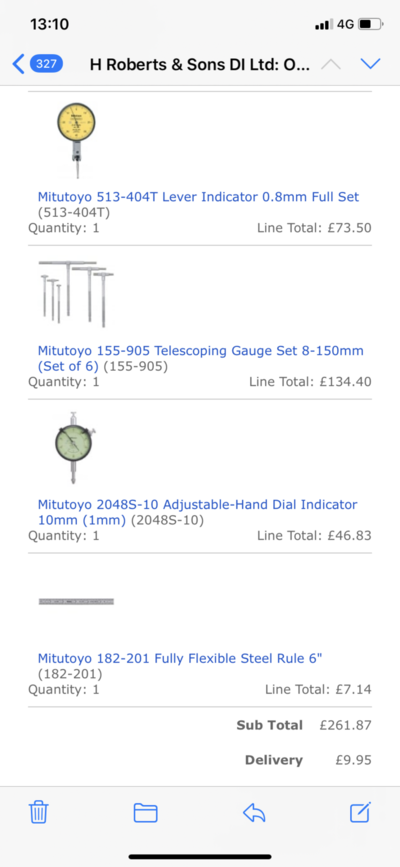

Only downside is if you need tight tolerances it can take a bit of work, these had to be +0/-0.02 for some strange reason, in fact I had to actually redo one because although it wasn't out of tol the tube was. Normally I measure the tube and make to suite but I was told to make to drawings so that is what I did.

Only downside is if you need tight tolerances it can take a bit of work, these had to be +0/-0.02 for some strange reason, in fact I had to actually redo one because although it wasn't out of tol the tube was. Normally I measure the tube and make to suite but I was told to make to drawings so that is what I did.