- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Machining Techniques and Materials

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you machining?

- Thread starter Kram

- Start date

Kram

Member

- Messages

- 8,459

- Location

- Sussex

Ive changed to a new 12mm chinese endmill, as I have no spare travel to drop work down. I am very suprised - its an open slot but it was quite happy 2mm deep cut, full width and moving fast, even happy 1mm deep climb milling. Im sure it will be worse with vertical raised higher.

I need a vice with a smaller bottom jaw, 30mm seems OTT, im sure 15mm would be adequate!? Ill get some csk bolts then I can drop another 10mm.

Dcal

Forum Supporter

- Messages

- 4,072

- Location

- Antrim Northern Ireland

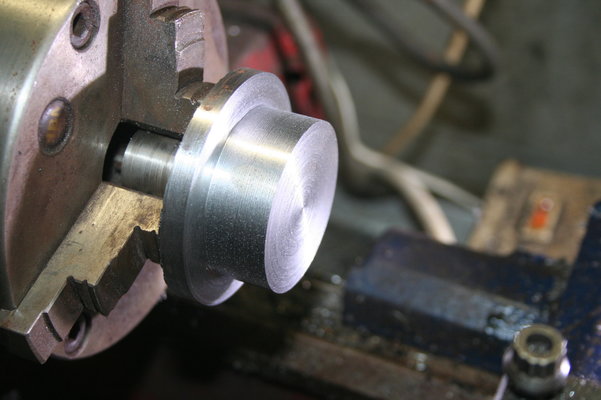

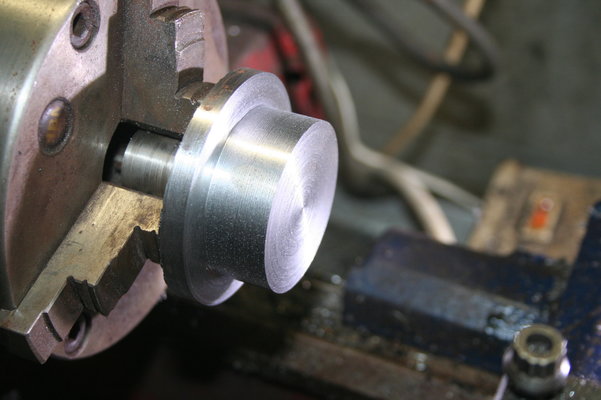

Today I machined another tipping wheel for the bead roller.

I have an earlier version that I welded and then machined (because I didn't have a big enough lump of bar) and that works fine.

This is for a mate but I might make one for myself as well.

It's made from a bit of tie-bar that came out of a harbour wall we were demolishing, I'm sure 20 years ago.

It was too big to fit in my 3 jaw and I should have put it in the little 4 jaw but instead I tack welded a bit of bar to it and mounted it in the chuck that way.

When I machined the first side down I was able to turn it and mount it in the chuck then use a parting tool to cut the bar off.

It didn't like it and broke the parting tool tip.

The heat affected zone was a hard as the hobs so there must be a bit of carbon in the bar.

This is good (I think) as I might have a go at hardening the whole thing.

The bar had hardened to a fair depth and was still hard 3mm in.

The rest went fine and I did clock it in the 4 jaw to finish off the other side.

Very simple thing but I'm quite pleased with it as it's about the level my machining skills have reached.

Has anyone any idea what grade steel a 70 year old 3 inch tie-bar would be made from?

I have an earlier version that I welded and then machined (because I didn't have a big enough lump of bar) and that works fine.

This is for a mate but I might make one for myself as well.

It's made from a bit of tie-bar that came out of a harbour wall we were demolishing, I'm sure 20 years ago.

It was too big to fit in my 3 jaw and I should have put it in the little 4 jaw but instead I tack welded a bit of bar to it and mounted it in the chuck that way.

When I machined the first side down I was able to turn it and mount it in the chuck then use a parting tool to cut the bar off.

It didn't like it and broke the parting tool tip.

The heat affected zone was a hard as the hobs so there must be a bit of carbon in the bar.

This is good (I think) as I might have a go at hardening the whole thing.

The bar had hardened to a fair depth and was still hard 3mm in.

The rest went fine and I did clock it in the 4 jaw to finish off the other side.

Very simple thing but I'm quite pleased with it as it's about the level my machining skills have reached.

Has anyone any idea what grade steel a 70 year old 3 inch tie-bar would be made from?

Today I machined another tipping wheel for the bead roller.

I have an earlier version that I welded and then machined (because I didn't have a big enough lump of bar) and that works fine.

This is for a mate but I might make one for myself as well.

It's made from a bit of tie-bar that came out of a harbour wall we were demolishing, I'm sure 20 years ago.

View attachment 216597

It was too big to fit in my 3 jaw and I should have put it in the little 4 jaw but instead I tack welded a bit of bar to it and mounted it in the chuck that way.

View attachment 216592

When I machined the first side down I was able to turn it and mount it in the chuck then use a parting tool to cut the bar off.

View attachment 216593

It didn't like it and broke the parting tool tip.

The heat affected zone was a hard as the hobs so there must be a bit of carbon in the bar.

This is good (I think) as I might have a go at hardening the whole thing.

The bar had hardened to a fair depth and was still hard 3mm in.

The rest went fine and I did clock it in the 4 jaw to finish off the other side.

View attachment 216594

Very simple thing but I'm quite pleased with it as it's about the level my machining skills have reached.

View attachment 216595

View attachment 216596

Has anyone any idea what grade steel a 70 year old 3 inch tie-bar would be made from?

Wrought iron!

zx9

Forum Supporter

- Messages

- 5,187

- Location

- South East London

Nice tip @Hopefuldave I will be using the tailstock for a bit more rigidity next time I am torturing the Drummond.Until you add support on the vertical... Bring the tailstock up and lock it against the back of the milling slide for the cut, helps add a bit of rigidity and you'll get a more consistent milling cut with a better finish - I used to do that (had topslide on a big angle plate bolted to the cross-slide tee slots) before I got my milling machine, it made milling on the lathe a bit less unpleasant!

Dave H. (the other one)

doubleboost

Member

- Messages

- 3,940

- Location

- Newcastle upon Tyne England

2 post hoist legs boring out worn threads to accept drip in feet

New power quill doing a splendid job

Woody.v8

Blue gluer

- Messages

- 4,212

- Location

- staffs

Balls! looks almost finished too, Gutting when that happens.

Well thats going in the bin. I made several mistakes. The biggest was I engaged the dial at two, where as the rest of cuts were at one.

I'll get some practise on scrap before I try this again..

doubleboost

Member

- Messages

- 3,940

- Location

- Newcastle upon Tyne England

Do the thread first

Agroshield

Member

- Messages

- 6,339

The biggest was I engaged the dial at two, where as the rest of cuts were at one.

I know your pain. A sharpie is good for marking thread dial numbers you need to use. A Post-it note is good for obscuring things you don't want to use.

Make some overlays for the TDI, possibly held on by magnets, that are pitch-specific and only have the useful numbers on.

Little known fact: Rick Wakeman used to do screwcutting as practice for playing two keyboards at once.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Well thats going in the bin. I made several mistakes. The biggest was I engaged the dial at two, where as the rest of cuts were at one.

I'll get some practise on scrap before I try this again..

Is it a metric leadscrew on the lathe? If not then it may be that you should keep the halfnuts engaged until the thread is complete.

zx9

Forum Supporter

- Messages

- 5,187

- Location

- South East London

Well thats going in the bin. I made several mistakes. The biggest was I engaged the dial at two, where as the rest of cuts were at one.

I'll get some practise on scrap before I try this again..

It is an absolute pain in the rump when that happens, fortunately I have never done quite that much work before before making a pigs ear of it. (yet)

Is it a metric leadscrew on the lathe? If not then it may be that you should keep the halfnuts engaged until the thread is complete.

As per @Hood above, it may not be the right way to go about it but it works. If like me you have a screw on chuck and are worried about running the lathe backwards, don't be too concerned, the tool is withdrawn using the cross slide for the reverse part so accidentally unscrewing the chuck at moderate speed is very unlikely.

On my to do list is an adjustable stop for the cross slide to make the process easier, no doubt I will remember half way through roughing out the next item I need to thread.

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,866

- Location

- East Yorkshire

Well thats going in the bin. I made several mistakes. The biggest was I engaged the dial at two, where as the rest of cuts were at one.

I'll get some practise on scrap before I try this again..

Feel your pain. Had the same happen to me a while back. Now I choose a number on the thread dial and stick with it. Takes longer as you always have to wait for it come round. Better than trashing the part though.

Dr.Al

Forum Supporter

- Messages

- 2,772

- Location

- Gloucestershire, UK

Feel your pain. Had the same happen to me a while back. Now I choose a number on the thread dial and stick with it. Takes longer as you always have to wait for it come round. Better than trashing the part though.

I tend to do this too - always engage at number 1 as it stops me being a prat. Having said that, I've got a non-screwed chuck so I tend to thread with the spindle running backwards and the tool upside down. As that gives a lot more time to disengage the half-nuts, I can run the lathe a lot faster than I would with a normal orientation tool (no risk of crashing into the work piece) so I don't have to wait as long for the thread dial to turn.