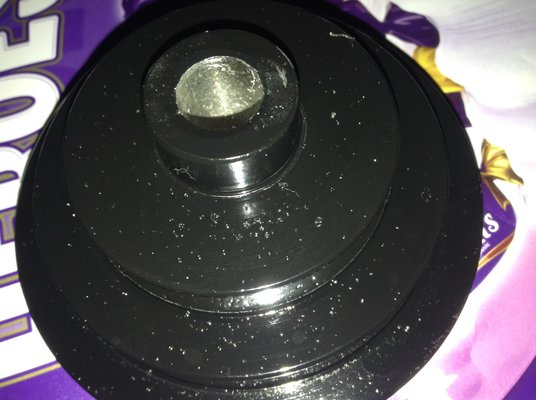

for the past couple of days Ive been making a new drive pulley for my lathe as one of the V's had worn and was wider than a new belt, so its a 3 speed stepped pulley, with one V being for a 6mm wide belt and 2 being for 8mm wide belts and the biggest largest diameter V is in the middle. lucky enough I had a chunk of alumium the right size.

the first thing I did was to grind a couple of form tools to the shape of the grooves as the have different angles

then turned the bank for the large step and one of the smaller steps and bored the centre out for the motor spindle

then the V was cut to depth with a parting tool

then the sides of the V are cut using the form tool in one go for each side of the V, 6mm wide using a madrel handle to get decent finish

the part completed pulley was then turned round and the third V was cut

the keyway was then cut using a 4mm square toolbit in boring bar tool holder. I was originally going to do this in my milling machine, but easier to set up in the lathe

taking a cut 0.05 mm at a time.

to stop the chuck from rotating the mandre handle was clamped to the lathe bed. the new pulley was to replace the on the back pulley (on the motor)

and then counterboring onr end of the bore as there was clearance issues with another pulley

the first thing I did was to grind a couple of form tools to the shape of the grooves as the have different angles

then turned the bank for the large step and one of the smaller steps and bored the centre out for the motor spindle

then the V was cut to depth with a parting tool

then the sides of the V are cut using the form tool in one go for each side of the V, 6mm wide using a madrel handle to get decent finish

the part completed pulley was then turned round and the third V was cut

the keyway was then cut using a 4mm square toolbit in boring bar tool holder. I was originally going to do this in my milling machine, but easier to set up in the lathe

taking a cut 0.05 mm at a time.

to stop the chuck from rotating the mandre handle was clamped to the lathe bed. the new pulley was to replace the on the back pulley (on the motor)

and then counterboring onr end of the bore as there was clearance issues with another pulley

Eventually got it apart and got them into the lathe and the flat face and taper skimmed, they are about 19-20inch diameter.

Eventually got it apart and got them into the lathe and the flat face and taper skimmed, they are about 19-20inch diameter. So off with the top plate again and back to the workshop and into the Chiron with it. Took a bit of messing to get things set up correctly as I had to be exactly 60 degrees offset from the original holes due to the inner plate being keyed and thus the bolt holes in both plates and also the key in the taper bush all need to align.

So off with the top plate again and back to the workshop and into the Chiron with it. Took a bit of messing to get things set up correctly as I had to be exactly 60 degrees offset from the original holes due to the inner plate being keyed and thus the bolt holes in both plates and also the key in the taper bush all need to align.