Robbie260

I fix things that others have broken

- Messages

- 2,472

- Location

- Scotland highland

So due to the impressive and seemingly limitless knowledge on this fourm We all collectively must have learned enough hits, tips, tricks, safe short cuts and elements of best practice in our lives that we could all share too help each other along in our quests.

Please keep them reasonalble and safe we do not want too encourage bad habits.

In elements of best practice/safety:

1. Sleeves should be rolled up or short when working on or with rotating machinery, ie lathes, bench griders, drill presses etc. Wearing a tie is also a big no no.

2. Gloves should never be worn while operating rotating machinery, ie bench grinders, drill presses, lathes etc. There are exceptions such as angle grinders.

3. Angle grinders should be when switched off placed on thier back with the disk facing up and allowed too run down of thier own accord not jammed into a work surface too stop them. When changing the disk the grinder should be unplugged from the wall.

4. If working on electrical machinery item should be unplugged if applicable, if not breaker should be locked in the open position and tagged out, and any fuses present removed. Appliance must be tested for dead, use a meter that can be proven for this ie test it on a known live source, test the isolated machine, test again on a known live source too ensure meter is working, some meters come with proving units or they are avalible seperately.

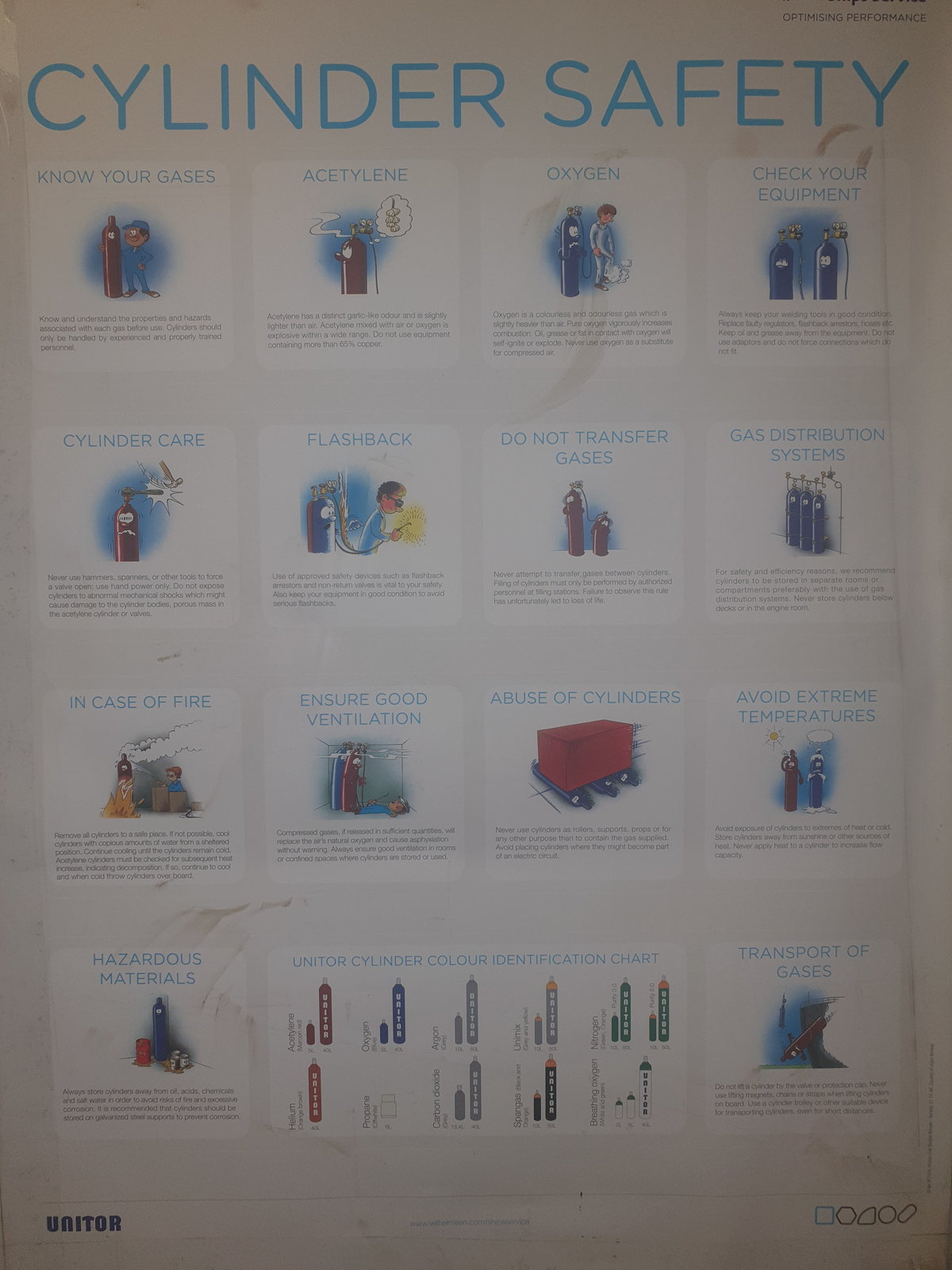

5. If an oxygen or acetylene cylinder has been knocked over or dropped continuous cooling should be applied immediately and emergency services phoned, if on board a sea going vessel cylinder should be dumped overboard at the earliest and safest opportunity.

6. Do not put your fingers anywhere you wouldnt be willing too put you private parts. The same gose for feet but you should be wearing appropriate safety footwear.

7. Do not look upon a part from above or below that is under tension or compression ie an bearing being removed by a puller, if it suddenly lets go its going too hit you in the face.

8. If working in an electrical cabinet you should be standing on an insulator like a rubber mat, if using a ladder the ladder should be wooden or made of a non conductive material such as fiberglass, if at all possible only put one hand in the cabinate, though most tasks admittedly require two.

9. If working under something ensure it is supported securely on properly rateded stands, jacks are not an acceptable support on thier own as they are prone too failure. This is particularly applicable too cars. If you dont have too jack it up too work on it dont.

10. Only lift stuff as high as you need too to move it. If it only needs too come an inch off the floor too have sufficent clearance too move it where it needs too be thats all you lift it. If it needs too go higher too clear an obstacle at a point when you get there lift it higher and ounce past lower it back down too the minimum lift hight required.

11. Electrical motor bearings should be greased while thee motor is running, if the motor bearing has a grease drain it should be open at this time too prevent grease building up and getting into the motor windings. Usually for small motors 1 or 2 strokes every 6 months will be sufficient.

12. Workshop first aid kit should be inventoried every month minimum too ensure it is fully stocked and there are no expired items/medicine's in it. It is advisable it contains any special medications you or any of your family members require in the case of a private home workshop if it is seperated from the main house.

13. If your skin comes into contact with pressurised hydraulic oil above 6 bar seek immediate medical attention, hydraulic oil at and above this pressure can cause blood poisoning.

14. While a face shield should always be worn while preforming cutting and grinding tasks it is rarely sufficent on its own and a minimum of safety glasses and preferably goggles should also be worn.

15. Tell people where you are or leave a note for them with an expected time you will be finished in the workshop/back so they will come and check and see that you are ok if you go over this time, if you get injured you dont want too be waiting any longer than you have too for help.

16. Welding, cutting, grinding or even cutting of wood should be done in a well ventilated area with sufficent air exchange from a clean source ie outside your work area. If not possible appropriate fume/dust masks or air fed helmets should be worn. Working out side is a good option in some cases but a dust/fume mask should still be worn as there will still be some stuff coming at you.

Im out of those for just now on too tips and tricks. To which i must credit some that i know too youtubers.

1. Freezing bearings or parts too get them too fit into a housing or other part. One way of doing this if no freezer is avalible is hold a can of air duster upside down the solvent eveporates fast enough too cool metal down too seriously negitive temperatures really quickly.

2. Heat bearings or parts too get them on too/over something. Do not heat up sealed for life bearings that come pre filled with grease this can bake the grease and dramatically reduce bearing life span. Ways too heat up bearings/parts are in oil baths over open flame or electric element or through fancy induction bearing heaters which are the beast as they ensure uniform and even heating of the bearing.

3. Aluminium cuts plastic, steel cuts aluminium and tungsten carbide cuts everything.

4. If wanting welds to maintain thier strength allow too air cool, dont cool under a tap, to help maintain greater strength place in an oven and gradually bring the temperature down over the period of an hour, or bury in sand for a few hours. This is assuming weld was done properly, correct prep, penetration etc.

5. Some Bubble gum is made of the same material as orings so it can be used inplace of them in an emergency of surfaces an oring wont seal on due too imperfections.

6. If you want too split a nut with out damaging the thread but dont have a nut splitter, grind down one flat of the nut by about 60-70% the hit with hammer and chissel and the nut should crack.

7. Again with splitting nuts. Impact wrencehes can be used with nut splitters but please wear appropriate protection it googles, facesheild etc. And grease the threads of the nut splitter first.

8. Heating and cooling of bolts can break rust bonds on stuck nuts, also clean the bolt threads with a wire brush before trying too remove it will help them come off easier.

9. Diesel, kerosene and petrol all make good cleaning solvents. If you want too protect the part use diesel or kero as it will leave a slight oil film behind on the part. Petrol will fully evaporate after cleaning so will leave no residue on the parts, handy for fine fit parts etc.

10. Ptfe tape locks too the threads of a fitting if it is used correctly, wind it on in the opposite direction as the fitting will tighten too ensure a good seal and so the tape dosent come undone as you screw the fitting in. No more than 3 rounds of tape should be used if more are required too gain an effective seal then the fitting should be replaced. Do not use ptfe tape on hydraulic fittings or on gas bottles.

11. Never ever tell someone when something will be done by as you can garuntee that is the exact time that it will be no where near finished by.

12. If your problem cant be solved by a hammer then its either not big enough or you aint hittimg it hard enough.

13. Metric and imperial spanners after size 24mm are almost all identical in size so why carry two sets except 30mm i believe but id have too check. Same also in the smaller sizes metric spanners have imperial equivalents so why carry both.

14. You can never have enough duct tape, cable ties, wd40 and super glue in your life.

15. Keep thread locker, super glue, etc in the fridge too extend its life,

16. Nail polish remover will remove super glue from fingers/other things.

Handy stuff too have around:

All please contribute and we will see where this can go.

Please keep them reasonalble and safe we do not want too encourage bad habits.

In elements of best practice/safety:

1. Sleeves should be rolled up or short when working on or with rotating machinery, ie lathes, bench griders, drill presses etc. Wearing a tie is also a big no no.

2. Gloves should never be worn while operating rotating machinery, ie bench grinders, drill presses, lathes etc. There are exceptions such as angle grinders.

3. Angle grinders should be when switched off placed on thier back with the disk facing up and allowed too run down of thier own accord not jammed into a work surface too stop them. When changing the disk the grinder should be unplugged from the wall.

4. If working on electrical machinery item should be unplugged if applicable, if not breaker should be locked in the open position and tagged out, and any fuses present removed. Appliance must be tested for dead, use a meter that can be proven for this ie test it on a known live source, test the isolated machine, test again on a known live source too ensure meter is working, some meters come with proving units or they are avalible seperately.

5. If an oxygen or acetylene cylinder has been knocked over or dropped continuous cooling should be applied immediately and emergency services phoned, if on board a sea going vessel cylinder should be dumped overboard at the earliest and safest opportunity.

6. Do not put your fingers anywhere you wouldnt be willing too put you private parts. The same gose for feet but you should be wearing appropriate safety footwear.

7. Do not look upon a part from above or below that is under tension or compression ie an bearing being removed by a puller, if it suddenly lets go its going too hit you in the face.

8. If working in an electrical cabinet you should be standing on an insulator like a rubber mat, if using a ladder the ladder should be wooden or made of a non conductive material such as fiberglass, if at all possible only put one hand in the cabinate, though most tasks admittedly require two.

9. If working under something ensure it is supported securely on properly rateded stands, jacks are not an acceptable support on thier own as they are prone too failure. This is particularly applicable too cars. If you dont have too jack it up too work on it dont.

10. Only lift stuff as high as you need too to move it. If it only needs too come an inch off the floor too have sufficent clearance too move it where it needs too be thats all you lift it. If it needs too go higher too clear an obstacle at a point when you get there lift it higher and ounce past lower it back down too the minimum lift hight required.

11. Electrical motor bearings should be greased while thee motor is running, if the motor bearing has a grease drain it should be open at this time too prevent grease building up and getting into the motor windings. Usually for small motors 1 or 2 strokes every 6 months will be sufficient.

12. Workshop first aid kit should be inventoried every month minimum too ensure it is fully stocked and there are no expired items/medicine's in it. It is advisable it contains any special medications you or any of your family members require in the case of a private home workshop if it is seperated from the main house.

13. If your skin comes into contact with pressurised hydraulic oil above 6 bar seek immediate medical attention, hydraulic oil at and above this pressure can cause blood poisoning.

14. While a face shield should always be worn while preforming cutting and grinding tasks it is rarely sufficent on its own and a minimum of safety glasses and preferably goggles should also be worn.

15. Tell people where you are or leave a note for them with an expected time you will be finished in the workshop/back so they will come and check and see that you are ok if you go over this time, if you get injured you dont want too be waiting any longer than you have too for help.

16. Welding, cutting, grinding or even cutting of wood should be done in a well ventilated area with sufficent air exchange from a clean source ie outside your work area. If not possible appropriate fume/dust masks or air fed helmets should be worn. Working out side is a good option in some cases but a dust/fume mask should still be worn as there will still be some stuff coming at you.

Im out of those for just now on too tips and tricks. To which i must credit some that i know too youtubers.

1. Freezing bearings or parts too get them too fit into a housing or other part. One way of doing this if no freezer is avalible is hold a can of air duster upside down the solvent eveporates fast enough too cool metal down too seriously negitive temperatures really quickly.

2. Heat bearings or parts too get them on too/over something. Do not heat up sealed for life bearings that come pre filled with grease this can bake the grease and dramatically reduce bearing life span. Ways too heat up bearings/parts are in oil baths over open flame or electric element or through fancy induction bearing heaters which are the beast as they ensure uniform and even heating of the bearing.

3. Aluminium cuts plastic, steel cuts aluminium and tungsten carbide cuts everything.

4. If wanting welds to maintain thier strength allow too air cool, dont cool under a tap, to help maintain greater strength place in an oven and gradually bring the temperature down over the period of an hour, or bury in sand for a few hours. This is assuming weld was done properly, correct prep, penetration etc.

5. Some Bubble gum is made of the same material as orings so it can be used inplace of them in an emergency of surfaces an oring wont seal on due too imperfections.

6. If you want too split a nut with out damaging the thread but dont have a nut splitter, grind down one flat of the nut by about 60-70% the hit with hammer and chissel and the nut should crack.

7. Again with splitting nuts. Impact wrencehes can be used with nut splitters but please wear appropriate protection it googles, facesheild etc. And grease the threads of the nut splitter first.

8. Heating and cooling of bolts can break rust bonds on stuck nuts, also clean the bolt threads with a wire brush before trying too remove it will help them come off easier.

9. Diesel, kerosene and petrol all make good cleaning solvents. If you want too protect the part use diesel or kero as it will leave a slight oil film behind on the part. Petrol will fully evaporate after cleaning so will leave no residue on the parts, handy for fine fit parts etc.

10. Ptfe tape locks too the threads of a fitting if it is used correctly, wind it on in the opposite direction as the fitting will tighten too ensure a good seal and so the tape dosent come undone as you screw the fitting in. No more than 3 rounds of tape should be used if more are required too gain an effective seal then the fitting should be replaced. Do not use ptfe tape on hydraulic fittings or on gas bottles.

11. Never ever tell someone when something will be done by as you can garuntee that is the exact time that it will be no where near finished by.

12. If your problem cant be solved by a hammer then its either not big enough or you aint hittimg it hard enough.

13. Metric and imperial spanners after size 24mm are almost all identical in size so why carry two sets except 30mm i believe but id have too check. Same also in the smaller sizes metric spanners have imperial equivalents so why carry both.

14. You can never have enough duct tape, cable ties, wd40 and super glue in your life.

15. Keep thread locker, super glue, etc in the fridge too extend its life,

16. Nail polish remover will remove super glue from fingers/other things.

Handy stuff too have around:

All please contribute and we will see where this can go.

, but being human and therefore fallible by inclination I suspect we will all [myself included

, but being human and therefore fallible by inclination I suspect we will all [myself included  ] forget them temporarily.....

] forget them temporarily.....