malcolm

& Clementine the Cat

- Messages

- 9,821

- Location

- Bedford UK

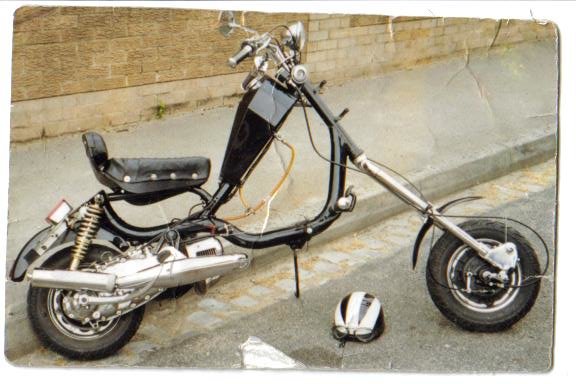

The poor Renault 4.

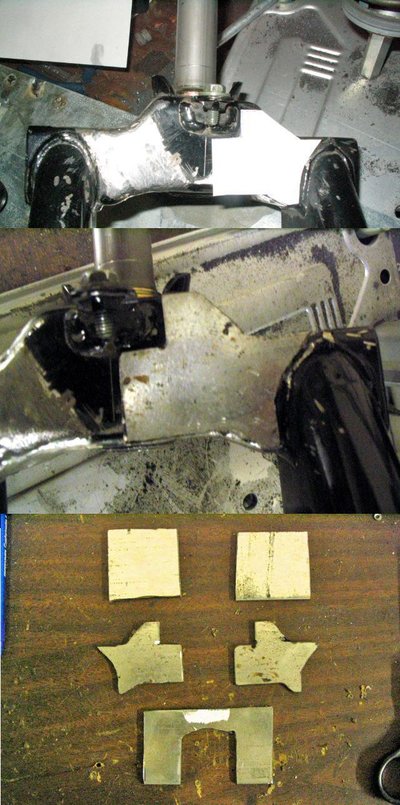

These days you can pick up a replacement engine for next to nothing. (There's one on eBay at the moment for 1p). The cars tend to rust in a really inaccessible area around the rear suspension that takes about 20 hours to repair properly, so the cars tend to be broken up rather than repaired. (If anyone feels they might get bored looking at car repairs then I have the web page for you: Clementine the cat welds a Renault 4 .

Cherish your R4 experience - there won't be any left soon (apart from the one or two I seem to get roped into repairing).

It's a shame as they are versatile cars. Mine has a 2m by 1m sheet of Aluminium in the boot at the moment. Must pull it out tonight as it has a paraffin coating and smells really bad.

These days you can pick up a replacement engine for next to nothing. (There's one on eBay at the moment for 1p). The cars tend to rust in a really inaccessible area around the rear suspension that takes about 20 hours to repair properly, so the cars tend to be broken up rather than repaired. (If anyone feels they might get bored looking at car repairs then I have the web page for you: Clementine the cat welds a Renault 4 .

Cherish your R4 experience - there won't be any left soon (apart from the one or two I seem to get roped into repairing).

It's a shame as they are versatile cars. Mine has a 2m by 1m sheet of Aluminium in the boot at the moment. Must pull it out tonight as it has a paraffin coating and smells really bad.

.

.