Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

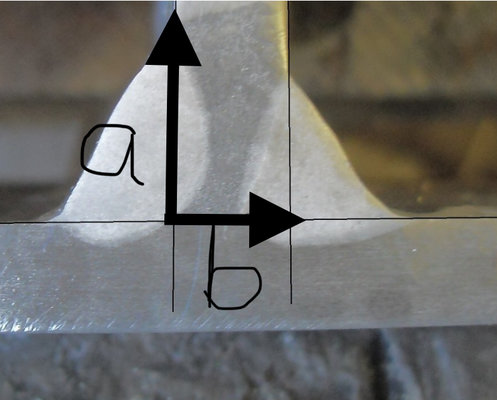

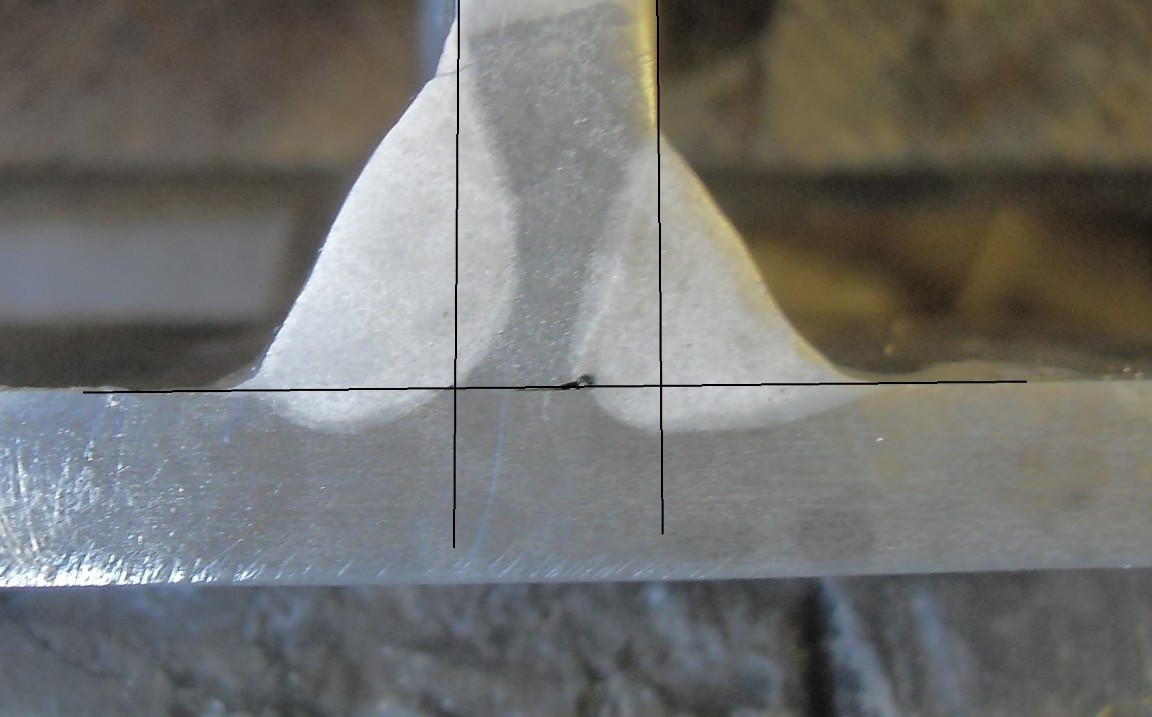

Hi Henry, the one I posted above that has the bad porosity was done in overhead position, I am still however putting it down to wire or possibly gas rather than position as I did another at the same time with the EWM and Esab wire and it came out good, well my position of the torch wasn't the best on one run but otherwise ok, see pic, possibly a speckle or two in them.

.

.