Dont apologise....its a minefield.........I was part of it for 40 yearsAah, not as simple as I naively thought - my apologies.

I'm newish to MIG welding but do fully appreciate the nuances of buying the right tool or consumables - I'm anal when it comes to abrasives for woodturning...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What’s your favorite wire?

- Thread starter Jetemp

- Start date

317 Stainless?....thats quite specialised........chemical tankers?I have some flux core Bohler 317 (I think) got from a localish place that were throwing it out as the job was finished and they don't carry over part used rolls to other jobs. Not tried it yet, keep meaning to but just never had the chance, I am told it is excellent though so time will tell if I am any good.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Yes, obviously I have never done X Rays however I have done quite a few chops/etches and don't see much in the way of porosity. Having said that I did get some in the tests the last day with the Cebora, not sure what wire it was as it didn't have a name on it but the supplier said he reckoned it was SWP. Can't say for sure whether it was the wire that was the problem though as I was using a burnt shroud and possibly had too much flow for the small torch, hopefully I can do some more tests next week to see if I can find the problem.You dont always "see" the difference in Ally wires..........X rays do though.......have you heard the term "shaved" wire?......this refers to surface treatment to remove surface contaminats that cause porosity...sometimes only visible on a graph

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Might be317 Stainless?....thats quite specialised........chemical tankers?

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

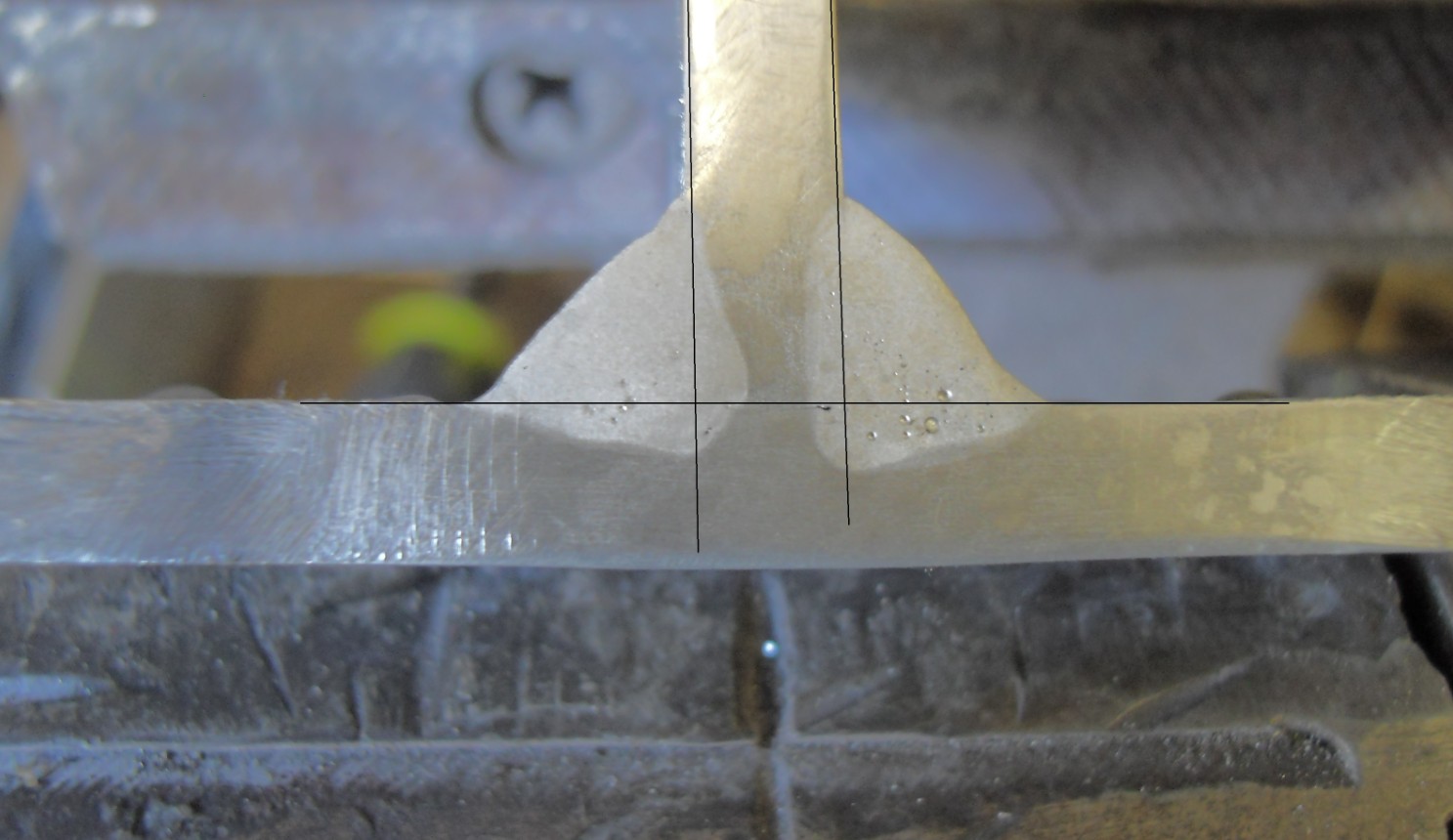

This was the one the last day, was happy enough with the profile and penetration (the wee Cebora is impressive ) but mightily pee'd off when I saw the bubbles

As said I have not found the issue yet for sure but the wire is the prime suspect.

As said I have not found the issue yet for sure but the wire is the prime suspect.

You always get porosity with Aluminium welds....its the quantity that variesYes, obviously I have never done X Rays however I have done quite a few chops/etches and don't see much in the way of porosity. Having said that I did get some in the tests the last day with the Cebora, not sure what wire it was as it didn't have a name on it but the supplier said he reckoned it was SWP. Can't say for sure whether it was the wire that was the problem though as I was using a burnt shroud and possibly had too much flow for the small torch, hopefully I can do some more tests next week to see if I can find the problem.

it always isThis was the one the last day, was happy enough with the profile and penetration (the wee Cebora is impressive ) but mightily pee'd off when I saw the bubbles

As said I have not found the issue yet for sure but the wire is the prime suspect.

View attachment 143387

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

It is very rare that I see porosity in an etch, I am sure it will be there but it is not really visible to the naked eye or at least not to me. I did once get plagued with a porosity problem that was driving me daft but I eventually traced it to a tiny pin hole in the gas hose.You always get porosity with Aluminium welds....its the quantity that varies

Aluminium always has porosity..........thats a factIt is very rare that I see porosity in an etch, I am sure it will be there but it is not really visible to the naked eye or at least not to me. I did once get plagued with a porosity problem that was driving me daft but I eventually traced it to a tiny pin hole in the gas hose.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

What are you talking though? Big bubbles as above or tiny ones that can hardly be seen?Aluminium always has porosity..........thats a fact

I have on occasion seen some close to the surface but the one above dismayed me because they were deep down.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

You seem to be getting me wrong, I am not disagreeing with you as I know it is true, I am simply trying to get a handle on what to normally expect.well done....they look good

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Do a google search for mig wire code and you should get info on it, for example here is one I just got by doing that.

http://gowelding.org/welding/mig-gmaw/electrode/

http://gowelding.org/welding/mig-gmaw/electrode/

henry Kadzielski

Member

- Messages

- 1,211

- Location

- Australia Wollongong

Good morning Hood.

I have my sample of welds put down on a flat plate of alli with Safra 5356 1.2mm, and I agree no bubbles at all in all the welds put down. However when I did my alli weld test fillet and overhead butt weld, in the fillet there was porosity. Had the results emailed back to me from the testing agent which stated it was a class 2 weld and that class one is not obtainable with mig process due to the porosity. They stated that they look at the size and location of the porosity to determine the weld quality. They gave me

They gave me

no problems

no problems

I have my sample of welds put down on a flat plate of alli with Safra 5356 1.2mm, and I agree no bubbles at all in all the welds put down. However when I did my alli weld test fillet and overhead butt weld, in the fillet there was porosity. Had the results emailed back to me from the testing agent which stated it was a class 2 weld and that class one is not obtainable with mig process due to the porosity. They stated that they look at the size and location of the porosity to determine the weld quality.

They gave me

They gave me

no problems

no problems