A pair of shouldered arbors or mandrels to hold gear blanks. I've been trying to practice some gear cutting on the Bridgeport to get familiar with it for a project. I tried using tapered arbors but found the blanks moved under the cutting forces. I think there's only 3 thou of interference on those type of arbors, and I'm using an 8dp cutter. I think the forces were too much. People demonstrate gear cutting on Youtube and often cut quite a delicate gear which I think is a bit of a con. The blanks were bored and reamed to size but I still had trouble. I did buy some medium strength Loctite to see if that might help but never got round to trying it.

The smaller one is one piece, En8 material. The larger one is En8 too but is two piece with a lump of plain mild steel welded on for the shoulder. They are both threaded M16 fine. The small one fits a 16mm bore. The larger fits a 25mm bored blank.

I did think about adding a keyway to prevent rotation but I'm the world's slowest machinist so thought I'd try and hurry the job along with what I had. Can always add one later.

The threads were die cut. The Bridgeport came in handy to keep the die square to the job.

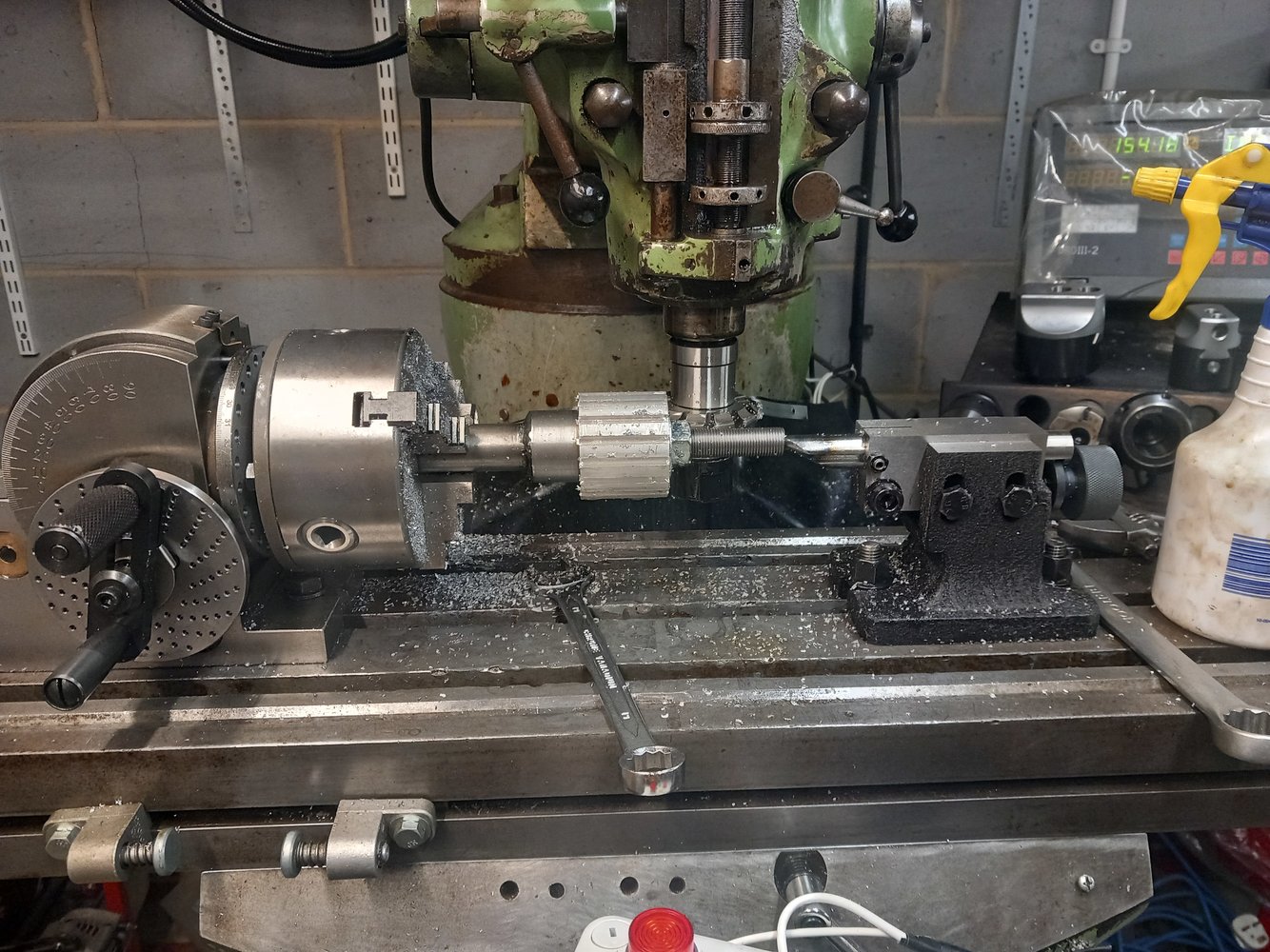

Set up on the mill. Apologies for greasy camera phone. I'm cuttting to a depth of 6.85mm There is 10mm clearance to the washer clamping the blank down,

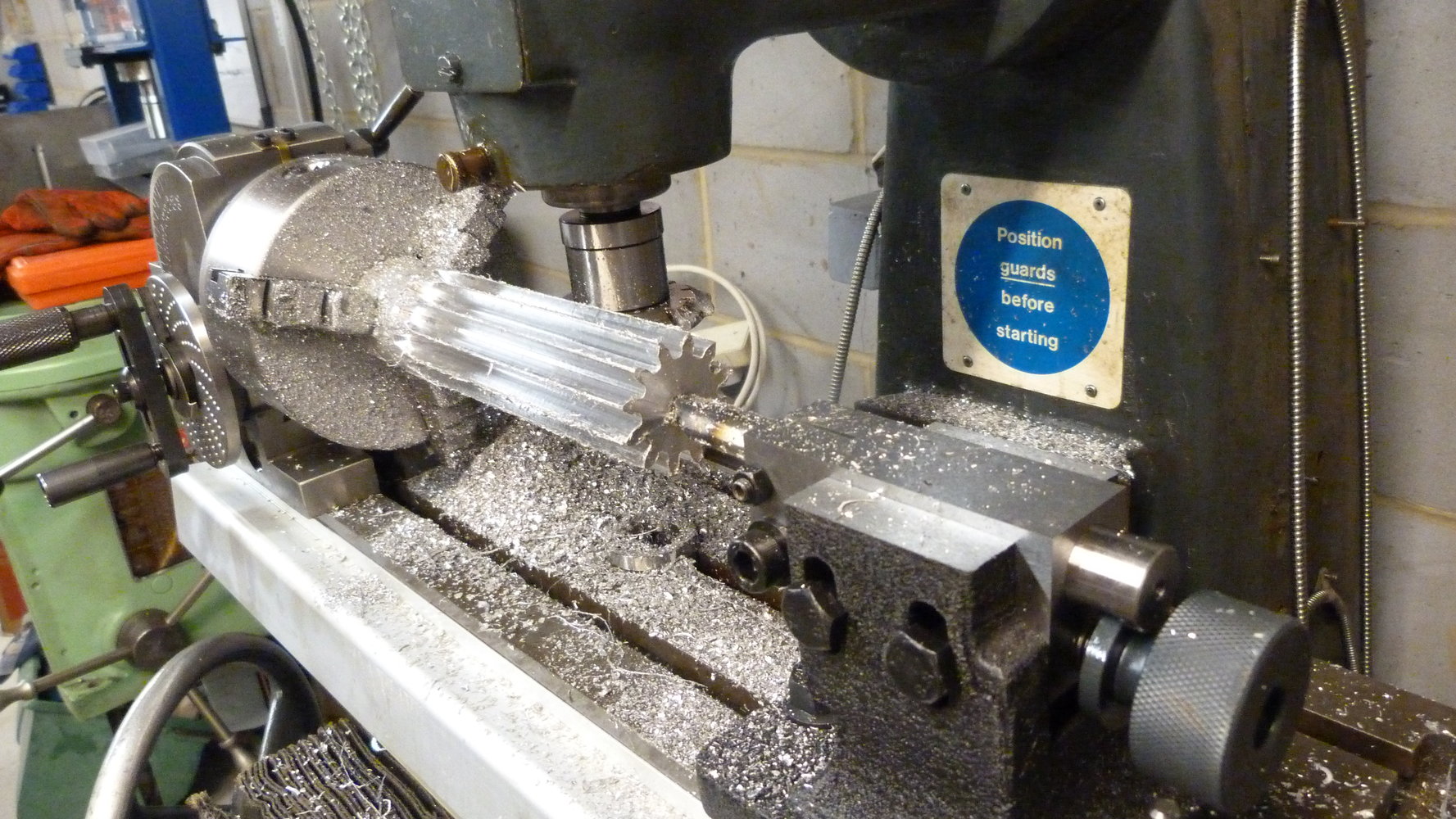

I last cut a similar gear (1.5 inch) on my smaller Marlow mill a couple of years ago. I didn't experience these problems then as I put the whole bar in the jaws of the dividing head and cut along it. The trouble with this solution is that it needs a lot of material to make clearance for the cutter at both ends and you do a lot of cutting which can promote wear on expensive cutters. Probably not a problem for aluminium but I want to do these cuts in steel. This is a pic from last time. I made three rather wide gears so there was actually little waste. I did attempt setting up again like this to cut a gear on the Bridgeport but the exterior surface of the ally bar is pretty rough and I couldn't get it set up accurately and indicated in. It wouldn't help me either as this setup wouldn't be useful for steel.

I'm cutting a 2" 16 tooth gear. The OD of the blank is 2 and a quarter inches. The 16 tooth gear turns out to be a nice, easy one to cut. The dividing head is geared 40 to 1, so there are exactly two and half turns to be made after each cut on the 20 hole plate. This means I am hitting the same two holes in the indexing plate, top and bottom each time. A bit of black felt tip helps if you mark them up. There was a lot of talking to myself as I counted the turns on the handle.

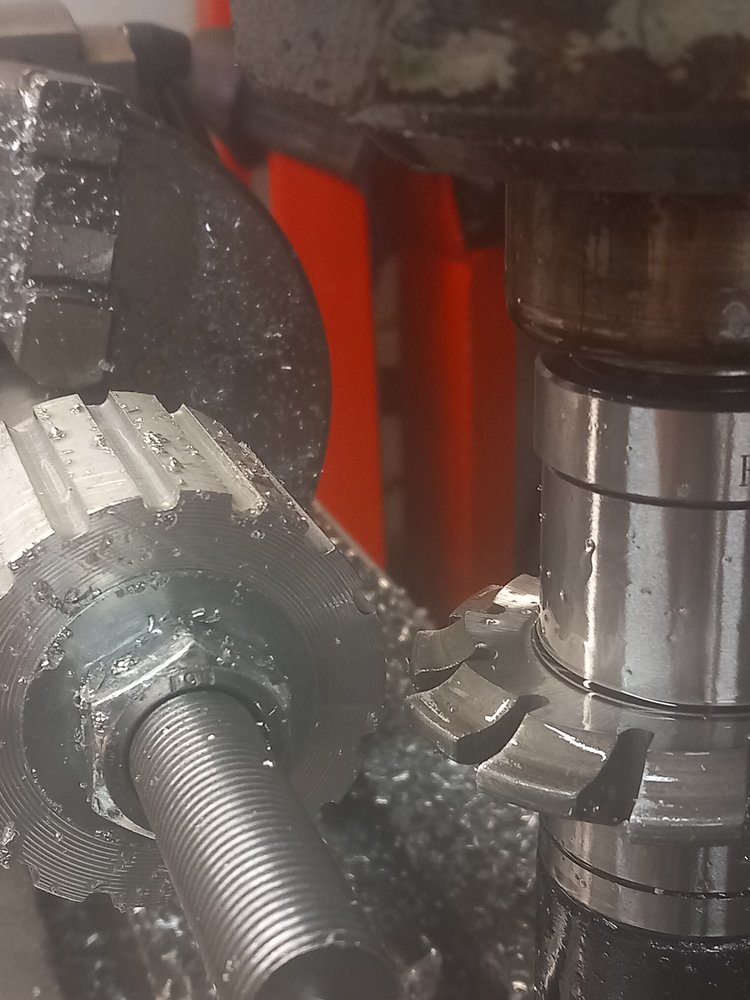

I made three revolutions with cut depths 2.4mm, 4.8mm and 6.85mm. 330 rpm. This pic below is the moment of truth cut with the last cut of the first rotation about to go in. Plenty of WD40 washed in. Success. The gear blank hasn't moved this time.

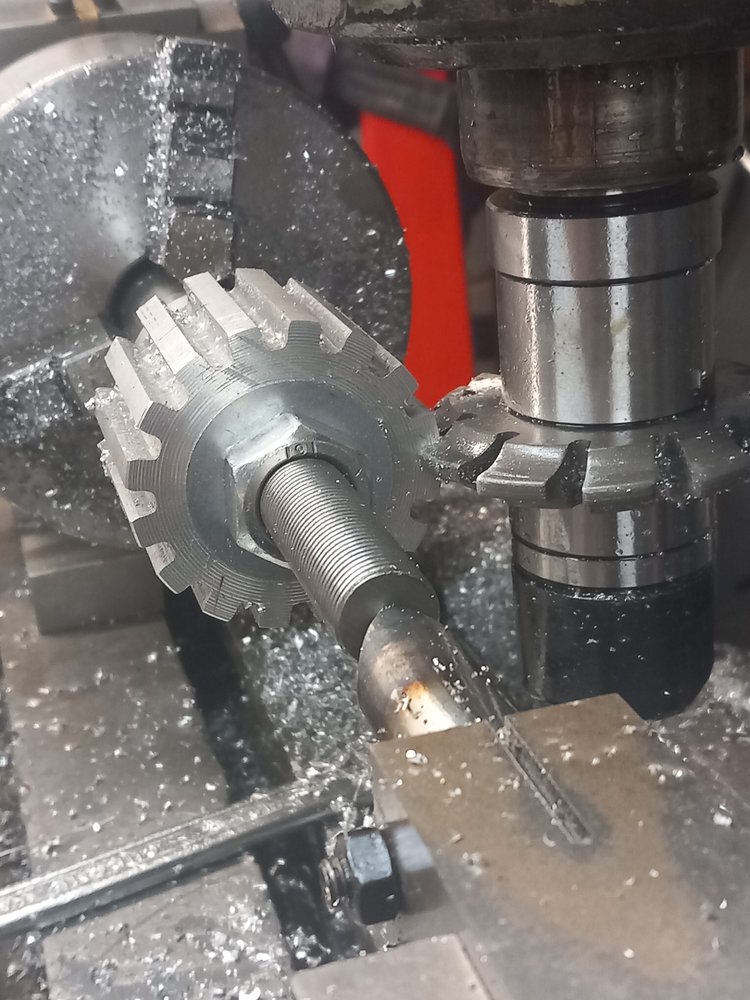

Bit deeper.

Final cut about to go in.

All the glitter brushed off.

Below is the final gear and the bar it was cut from. There's also a couple of mistakes from earlier showing too. I was tired and miscounted my turns on the partially cut blank. At least it was useful for trying out my keyway broach. The other gear with the dodgy spacing demonstrates my original problem. The measured intervals were a little too much and varied so there wasn't much left by the last cut. It seemed ok ish until then.

I had a little bit of trouble with the nut on the gear cutter arbour undoing itself a couple of times but I caught it in time. I think the gear cutter just followed the earlier cuts anyway as it came loose fairly late on. Something to get into the habit of checking in future. The nut on the home made arbor didn't budge. The thread is on the tight side. It is a lot easier and quicker cutting on the Bridgeport than the Marlow. I tested the gear against a spare gear cut on the Marlow and they rotate around each other fine. Close enough for government work and for what I need it to do.

The smaller one is one piece, En8 material. The larger one is En8 too but is two piece with a lump of plain mild steel welded on for the shoulder. They are both threaded M16 fine. The small one fits a 16mm bore. The larger fits a 25mm bored blank.

I did think about adding a keyway to prevent rotation but I'm the world's slowest machinist so thought I'd try and hurry the job along with what I had. Can always add one later.

The threads were die cut. The Bridgeport came in handy to keep the die square to the job.

Set up on the mill. Apologies for greasy camera phone. I'm cuttting to a depth of 6.85mm There is 10mm clearance to the washer clamping the blank down,

I last cut a similar gear (1.5 inch) on my smaller Marlow mill a couple of years ago. I didn't experience these problems then as I put the whole bar in the jaws of the dividing head and cut along it. The trouble with this solution is that it needs a lot of material to make clearance for the cutter at both ends and you do a lot of cutting which can promote wear on expensive cutters. Probably not a problem for aluminium but I want to do these cuts in steel. This is a pic from last time. I made three rather wide gears so there was actually little waste. I did attempt setting up again like this to cut a gear on the Bridgeport but the exterior surface of the ally bar is pretty rough and I couldn't get it set up accurately and indicated in. It wouldn't help me either as this setup wouldn't be useful for steel.

I'm cutting a 2" 16 tooth gear. The OD of the blank is 2 and a quarter inches. The 16 tooth gear turns out to be a nice, easy one to cut. The dividing head is geared 40 to 1, so there are exactly two and half turns to be made after each cut on the 20 hole plate. This means I am hitting the same two holes in the indexing plate, top and bottom each time. A bit of black felt tip helps if you mark them up. There was a lot of talking to myself as I counted the turns on the handle.

I made three revolutions with cut depths 2.4mm, 4.8mm and 6.85mm. 330 rpm. This pic below is the moment of truth cut with the last cut of the first rotation about to go in. Plenty of WD40 washed in. Success. The gear blank hasn't moved this time.

Bit deeper.

Final cut about to go in.

All the glitter brushed off.

Below is the final gear and the bar it was cut from. There's also a couple of mistakes from earlier showing too. I was tired and miscounted my turns on the partially cut blank. At least it was useful for trying out my keyway broach. The other gear with the dodgy spacing demonstrates my original problem. The measured intervals were a little too much and varied so there wasn't much left by the last cut. It seemed ok ish until then.

I had a little bit of trouble with the nut on the gear cutter arbour undoing itself a couple of times but I caught it in time. I think the gear cutter just followed the earlier cuts anyway as it came loose fairly late on. Something to get into the habit of checking in future. The nut on the home made arbor didn't budge. The thread is on the tight side. It is a lot easier and quicker cutting on the Bridgeport than the Marlow. I tested the gear against a spare gear cut on the Marlow and they rotate around each other fine. Close enough for government work and for what I need it to do.

Last edited: