- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Machining Techniques and Materials

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you machining?

- Thread starter Kram

- Start date

zx9

Forum Supporter

- Messages

- 5,187

- Location

- South East London

I might have bitten off more than I can chew!

View attachment 228906

...

Edit: More posts to follow as I progress.

A little more progress.

First time I have ground or used a form tool.

Which turned out ok especially as it was between centres, a little bit of chatter but some good cuts as well, lots of Rocol RTD was used.

This was the set up which I removed prior to setting the off axis for the taper turning.

Note cut up Pepsi can to hopefully protect the knurl, and the result.

The end which will be threaded got a bit chewed, I could not get a nice angle on the tool and resorted in using an insert tool, I should have ground up a thin HSS bit.

I am getting into HSS now.

More updates to follow when I have got the taper done.

pressbrake1

Member

- Messages

- 5,553

- Location

- Essex

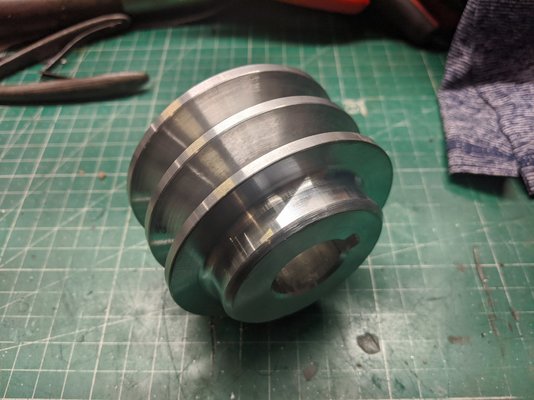

Lump of 200mm chrome round in the dsg being made into something else round..

Machine must be 65 years old and still produces finish close to ground

Machine must be 65 years old and still produces finish close to ground

slim_boy_fat

Member

- Messages

- 29,187

- Location

- Scottish Highlands

Machine must be 65 years old and still produces finish close to ground

Won't that be more to do with the cutting tools than the age of the machine?

pressbrake1

Member

- Messages

- 5,553

- Location

- Essex

NoWon't that be more to do with the cutting tools than the age of the machine?

pressbrake1

Member

- Messages

- 5,553

- Location

- Essex

Knux , hss wouldn’t survive chrome.Great finish. HSS?

Big mass and rigidity exceptional design and overall quality equals finish

grim_d

Unlikeable idiot.

- Messages

- 4,160

- Location

- Scotland - Ayrshire

Yeah it does because I ground it from something that already did. I've certainly not been clever...

I can remove it easy enough, having trouble visualising why it's no good but it's late and I'm stupid.

Edit: it just clicked. Idiot. I shall make another.

I can remove it easy enough, having trouble visualising why it's no good but it's late and I'm stupid.

Edit: it just clicked. Idiot. I shall make another.

Knux , hss wouldn’t survive chrome.

Big mass and rigidity exceptional design and overall quality equals finish

They definitely help but plenty of people get very nice finishes on tiny little lathes.

Perhaps not on chrome though?

Agroshield

Member

- Messages

- 6,341

View from the top, dotted lines showing original angle.

So can you do it the other way with the 3D model? Start with say 5 degrees top rake and a bit of side rake and determine what angle you would need to grind at to achieve a true 60 degrees plan view.

pressbrake1

Member

- Messages

- 5,553

- Location

- Essex

Naturally but when you’ve got half a ton of knarly old poop swinging and a damaged used insert and get good finish it takes a good lathe.They definitely help but plenty of people get very nice finishes on tiny little lathes.

Perhaps not on chrome though?

I should re state it as ‘ dsg that’s done 65 years of work still gets exceptional finish no matter the material or condition of the tool’

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

I would imagine so but you could just as easily regrind the tool as is until it just kisses the back edge, assuming that you can accurately set the angle of the grinder you are using.So can you do it the other way with the 3D model? Start with say 5 degrees top rake and a bit of side rake and determine what angle you would need to grind at to achieve a true 60 degrees plan view.

In reality the tool above is likely very close to the required angle anyway.