- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Machining Techniques and Materials

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you machining?

- Thread starter Kram

- Start date

pressbrake1

Member

- Messages

- 5,553

- Location

- Essex

Soppy apprentice did that trick, trouble was the Burke decided to use a pillar drill.

Leave outcome to the imagination

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,866

- Location

- East Yorkshire

Soppy apprentice did that trick, trouble was the Burke decided to use a pillar drill.

Leave outcome to the imagination

I drilled straight though my mates thumb with 1/8" drill while holding a frame together. I did ask him if it was clear. He retorted with’ just get it f’in drilled. Sure enough 20secs later choice words from him, could hardly blame me

Hopefuldave

Intergalactic pot-mender

- Messages

- 2,492

- Location

- The Shed of Danger, surrey, England

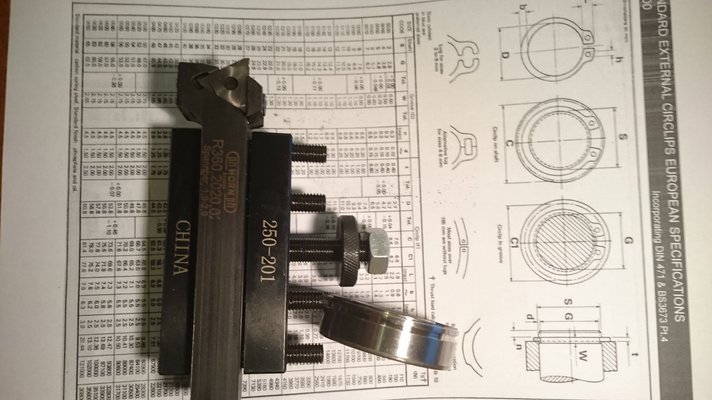

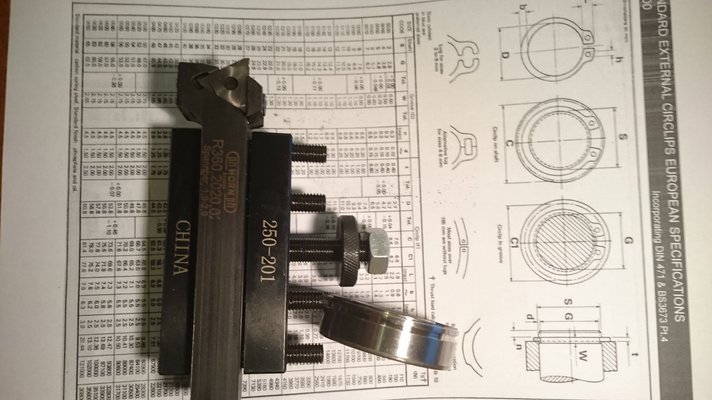

Took 5mm off the bottom of the Posh Grooving Tool I bought a couple of years ago at a carboot - Chinese EvilBay inserted carbide face mill did a good job on the Horn tool holder, a few sparks flew... Holder was through-hard, the burrs left defeated a cheap file, had to bring out the posh branded ones!

Then followed up with trying it putting a circlip groove in a bearing outer race to see whether I can get around the Unobtainium bearings in the Holbrook QCGB - some nice glowing ribbons, impressed by the Horn tool!

Dave H. (the other one)

Then followed up with trying it putting a circlip groove in a bearing outer race to see whether I can get around the Unobtainium bearings in the Holbrook QCGB - some nice glowing ribbons, impressed by the Horn tool!

Dave H. (the other one)

mtt.tr

Member

- Messages

- 8,137

- Location

- Essex/Suffolk border

Nothing exciting had to drill some 316 bushes for the poly bushes

100mm depth 12mm dia

Much in the vein of @grim_d cheap carbide insert post these are cheap hss drills ground with a 6 facet point which makes them pretty chip resident

Had adapt the boring bar Holder to take er25 collets makes peck drilling possible and keeping the pressure on

100mm depth 12mm dia

Much in the vein of @grim_d cheap carbide insert post these are cheap hss drills ground with a 6 facet point which makes them pretty chip resident

Had adapt the boring bar Holder to take er25 collets makes peck drilling possible and keeping the pressure on

doubleboost

Member

- Messages

- 3,940

- Location

- Newcastle upon Tyne England

After a bit of head scratching i came up with this set up

mtt.tr

Member

- Messages

- 8,137

- Location

- Essex/Suffolk border

Something from the bin, about 4 months ago i collected a bag of machine parts and tooling I've collected over about 12 years maybe little longer.

At the bottom of this bag was a very abused thread gauge threads all knocked of and 16 tpi stamped on it. Puzzled i realised it was the first proper thread i cut i was about 13-14 that's now 13 years ago i was doing an internal thread for something i couldn't remove the shaft so cut an outside external thread to use as a gauge.

This would of been hand ground hss tooling, not sure how i ended up a cabinet maker/carpenter

Better late than never to share, as far as i know the other part is still in use lost contact with them a long time ago

At the bottom of this bag was a very abused thread gauge threads all knocked of and 16 tpi stamped on it. Puzzled i realised it was the first proper thread i cut i was about 13-14 that's now 13 years ago i was doing an internal thread for something i couldn't remove the shaft so cut an outside external thread to use as a gauge.

This would of been hand ground hss tooling, not sure how i ended up a cabinet maker/carpenter

Better late than never to share, as far as i know the other part is still in use lost contact with them a long time ago

mtt.tr

Member

- Messages

- 8,137

- Location

- Essex/Suffolk border

127T gear made again, went perfectly this time.

Still rings like mad, need to start adding sound deadening.

View attachment 228007

Do you have any pics of the setup? I assume you used a dividing head?

grim_d

Unlikeable idiot.

- Messages

- 4,160

- Location

- Scotland - Ayrshire

Do you have any pics of the setup? I assume you used a dividing head?

Post #684 shows the setup on the last attempt, yep a dividing head with a compound gear train.

The only changes I made this time were some items to increase rigidity during the cut, the blank was pressed against the chuck jaws and was g-clamped to the chuck also, helped enormously.

Post #684 shows the setup on the last attempt, yep a dividing head with a compound gear train.

The only changes I made this time were some items to increase rigidity during the cut, the blank was pressed against the chuck jaws and was g-clamped to the chuck also, helped enormously.

Very nice - what size/make dividing head is that?

What are you using the gearing for? I thought that was only for spiral/helical stuff?

grim_d

Unlikeable idiot.

- Messages

- 4,160

- Location

- Scotland - Ayrshire

Very nice - what size/make dividing head is that?

What are you using the gearing for? I thought that was only for spiral/helical stuff?

It's a 9.5" Victoria, I've got a riser plate to make it 10" though. I paid through the nose for it because it came with all its accessories.

In addition to spiral milling the gearing allows you to divide anything up to about 380 iirc with only the two hole plates. It rotates the plates with the spindle effectively giving you more hole circles. I don't believe there's any other way to do 127T unless you direct index?

It's a 9.5" Victoria, I've got a riser plate to make it 10" though. I paid through the nose for it because it came with all its accessories.

In addition to spiral milling the gearing allows you to divide anything up to about 380 iirc with only the two hole plates. It rotates the plates with the spindle effectively giving you more hole circles. I don't believe there's any other way to do 127T unless you direct index?

I bet you did pay a fortune for it. Very nice though.

Agroshield

Member

- Messages

- 6,339

Using the centre bush that will hold them cut a couple of teeth plunge in. Creates a perfect tight fit.

I have just seen a similar concept in Ian Bradley's Myford book for cutting rubber hose: clamp a single-edged razor blade into a block of steel and slice it. Plain water as a lubricant. Maybe this could be useful to you in the other direction.

Kram

Member

- Messages

- 8,459

- Location

- Sussex

Still rings like mad, need to start adding sound deadening.

You'll have to do it again in delrin

I imagine a couple of face grooves filled with plastic/epoxy/rubber could absorb any ringing?

grim_d

Unlikeable idiot.

- Messages

- 4,160

- Location

- Scotland - Ayrshire

You'll have to do it again in delrin

I imagine a couple of face grooves filled with plastic/epoxy/rubber could absorb any ringing?

If it wasn't for the cost I probably would have, in fact now I know how easy it is I might be willing to buy a bit.

Yeah I was thinking that but one of my buddies has some self adhesive sound deadening I'm going to try first.

Edit: just checked, about £35 for a bit, not terrible.

grim_d

Unlikeable idiot.

- Messages

- 4,160

- Location

- Scotland - Ayrshire

I self adhesive sound deadening I'm going to try first.

Worked a treat, ringing completely gone.

It shown up another noise somewhere though but one thing at a time.