- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Machining Techniques and Materials

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you machining?

- Thread starter Kram

- Start date

Milkybars

Member

- Messages

- 1,279

- Location

- Essex

Been busy making a Lead screw nut for the Mk1 Clarkson I am resurrecting.

I have been patiently wating for a 5/8 BSW Left hand tap to arrive (I bought 19 !! or ebay all L.A.L ex army surplus apparently, brand new) So if anyone needs one drop me a line

The lead screw it's self is in fine order but the bronze nut was fubared.

The lathe work was fairly straight forward, but drilling the bronze out to 35/64" and then tapping it was tough going.

That all said very happy with the results all test fitted and it's sweet

I have been patiently wating for a 5/8 BSW Left hand tap to arrive (I bought 19 !! or ebay all L.A.L ex army surplus apparently, brand new) So if anyone needs one drop me a line

The lead screw it's self is in fine order but the bronze nut was fubared.

The lathe work was fairly straight forward, but drilling the bronze out to 35/64" and then tapping it was tough going.

That all said very happy with the results all test fitted and it's sweet

Brad93

Member

- Messages

- 19,444

- Location

- Essex, United Kingdom

I’d be interested in adding one to the collection.Been busy making a Lead screw nut for the Mk1 Clarkson I am resurrecting.

I have been patiently wating for a 5/8 BSW Left hand tap to arrive (I bought 19 !! or ebay all L.A.L ex army surplus apparently, brand new) So if anyone needs one drop me a line

The lead screw it's self is in fine order but the bronze nut was fubared.

The lathe work was fairly straight forward, but drilling the bronze out to 35/64" and then tapping it was tough going.

That all said very happy with the results all test fitted and it's sweet

Dcal

Member

- Messages

- 4,094

- Location

- Antrim Northern Ireland

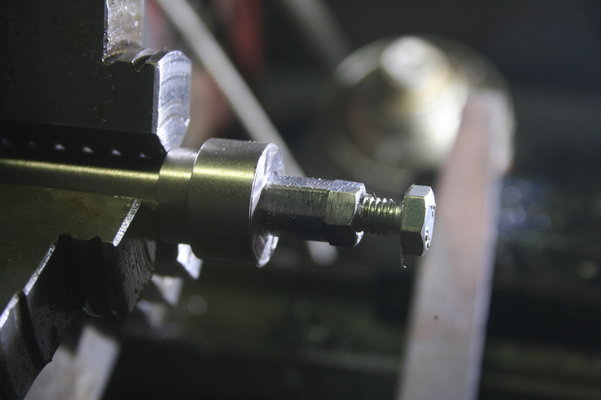

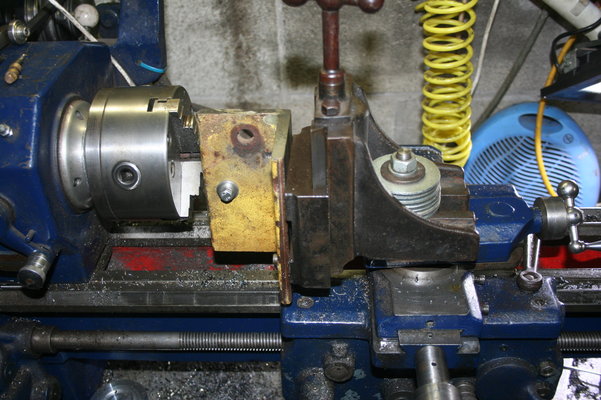

I've been "trying" to machine a shaft to fit a bristle blaster attachment on to a cheap sander polisher.

The proper bristle blasters are expensive and I can't justify spending several hundreds of pounds on one.

They try and make as many of the parts special to lock you into buying from them, like making the nut the head attaches to, M6 but just 9mm across the flats.

The turning went ok.

I don't have a mill so I just filed the 9mm flats on the end of the shaft.

I put a m6 nut and bolt on as a guide and checked as I went and it worked out ok. (well maybe for a beginner)

To finish the job I needed to cut a slot for a woodruff key and that’s where it started to go wrong.

Not only do I not have a mill I don’t have a woodruff cutter, let alone one the right size.

I also know next to nothing about woodruff keys or how they are sized so just tried various washers until I got one close.

I didn’t let any of these details get in the way and decided to try and make a cutter from what I had.

I do have (I think) a milling attachment for a lathe that I got on here some time ago so fitted that.

The only way I could think of holding the shaft was to bolt some 4 inch angle to the milling a attachment and fix the shaft to that.

I did at least flatten the mounting face for the vice as it was rocking.

Drilled and tapped and fitted to the milling attachement and bolted to the cross slide with lots of big washers.

If that wasn’t dodgy enough I then made a cutter from a 3/8 bolt and a parting insert.

Tried tig first to braze the insert to the bolt but that was not a success.

Next one I did with gas and that worked better.

It even made an attempt at cutting a slot untill the shaft moved and I made a complete hash of it.

I could fit the key and I got the gear hammered over it but precision engineering it is not

I took a break and went to bed, next day I had a search and I think I need a 13.5 x 4mm woodruff cutter. I turned a 13.5 x 4 disc and it's a nice enough fit.

Anyone know of a reasonable source?

It's not going to get used much so don’t want to spend much.

Cheapest I’ve seen are the Chronos ones, are they worth a try?

I also assume I need to do a better job of clamping the shaft.

https://www.chronos.ltd.uk/product/sct-woodruff-cutter-13-5-mm-diameter-x-4-mm/

The proper bristle blasters are expensive and I can't justify spending several hundreds of pounds on one.

They try and make as many of the parts special to lock you into buying from them, like making the nut the head attaches to, M6 but just 9mm across the flats.

The turning went ok.

I don't have a mill so I just filed the 9mm flats on the end of the shaft.

I put a m6 nut and bolt on as a guide and checked as I went and it worked out ok. (well maybe for a beginner)

To finish the job I needed to cut a slot for a woodruff key and that’s where it started to go wrong.

Not only do I not have a mill I don’t have a woodruff cutter, let alone one the right size.

I also know next to nothing about woodruff keys or how they are sized so just tried various washers until I got one close.

I didn’t let any of these details get in the way and decided to try and make a cutter from what I had.

I do have (I think) a milling attachment for a lathe that I got on here some time ago so fitted that.

The only way I could think of holding the shaft was to bolt some 4 inch angle to the milling a attachment and fix the shaft to that.

I did at least flatten the mounting face for the vice as it was rocking.

Drilled and tapped and fitted to the milling attachement and bolted to the cross slide with lots of big washers.

If that wasn’t dodgy enough I then made a cutter from a 3/8 bolt and a parting insert.

Tried tig first to braze the insert to the bolt but that was not a success.

Next one I did with gas and that worked better.

It even made an attempt at cutting a slot untill the shaft moved and I made a complete hash of it.

I could fit the key and I got the gear hammered over it but precision engineering it is not

I took a break and went to bed, next day I had a search and I think I need a 13.5 x 4mm woodruff cutter. I turned a 13.5 x 4 disc and it's a nice enough fit.

Anyone know of a reasonable source?

It's not going to get used much so don’t want to spend much.

Cheapest I’ve seen are the Chronos ones, are they worth a try?

I also assume I need to do a better job of clamping the shaft.

https://www.chronos.ltd.uk/product/sct-woodruff-cutter-13-5-mm-diameter-x-4-mm/

daleyd

Member

- Messages

- 10,552

- Location

- Wrexham, North Wales

Set of bronze bushes for a mates old lathe, 3" O/D and 2 1/4" I/D with oversize flanges to bolt in position with countersunk screws.

Drilled the tops to accept a 6mm grease nipple and ran a fine spiral grease groove on the inside.

Agroshield

Member

- Messages

- 6,397

Cheapest I’ve seen are the Chronos ones, are they worth a try?

Has it absolutely got to be a woodruff key? Could you use a 4mm endmill in the lathe chuck, shaft in vertical slide and put in a parallel key? Or drill two holes either end and use the shaper turned by hand to plane a keyway?

Dcal

Member

- Messages

- 4,094

- Location

- Antrim Northern Ireland

Has it absolutely got to be a woodruff key? Could you use a 4mm endmill in the lathe chuck, shaft in vertical slide and put in a parallel key? Or drill two holes either end and use the shaper turned by hand to plane a keyway?

This is what I need to try and replicate with my gauge for checking the slot size.

There is just a circlip in front of the keyway so both your options would work.

I think I'll still try and cut a woodruff slot just for the exercise, I can try it out on the scrap shaft.

Thanks for the ideas, another (more informed) perspective is always good.

Dcal

Member

- Messages

- 4,094

- Location

- Antrim Northern Ireland

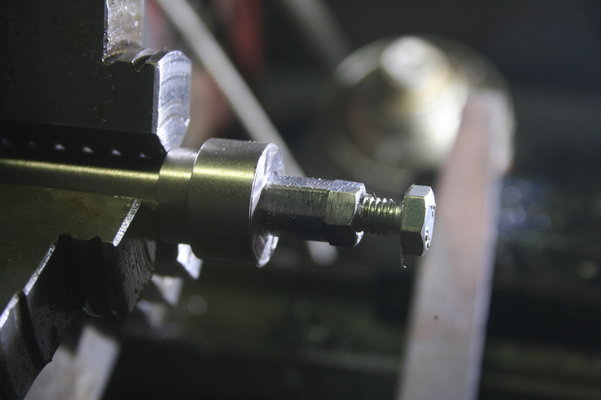

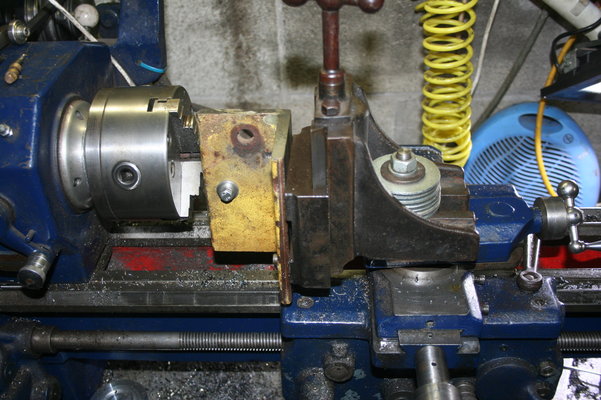

I’m trying to make an adapter so I can fit bristle blaster brushes in the polisher I'm playing with.

It a really tricky shape (I think) and I don't have a mill or the skills.

This is the part. The two half’s are identical and fit together nicely.

I don't have any alloy big enough, so built out some smaller round bar with tig.

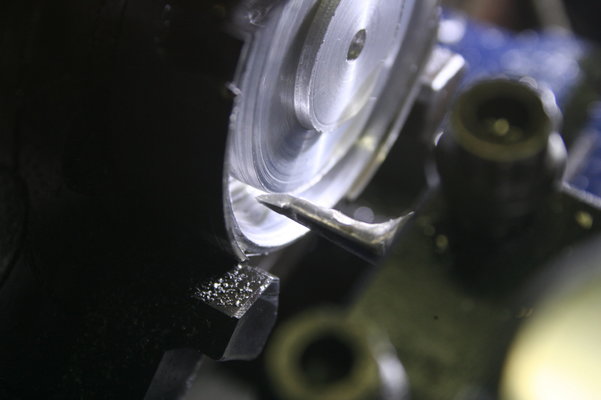

I thought I could get in with an insert cut-off tool but there wasn’t enough back clearance so I brazed a carbide cut-off insert to an old brazed carbide tool that had lost it's tip.

I needed to shorten the insert and boy are they hard to cut, even with a grinder.

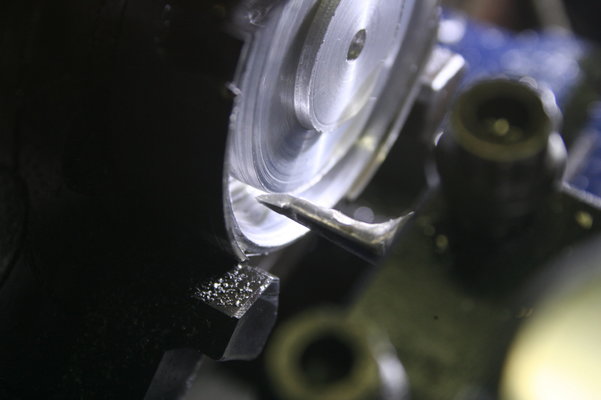

I then ground down a HSS blank to make a tiny boring bar to try and get the left side of the slot.

It sort of worked but was very slow and I still have the problem of cutting out the segments.

Is there a way to do this on a lathe?

What tools are normally used?

It a really tricky shape (I think) and I don't have a mill or the skills.

This is the part. The two half’s are identical and fit together nicely.

I don't have any alloy big enough, so built out some smaller round bar with tig.

I thought I could get in with an insert cut-off tool but there wasn’t enough back clearance so I brazed a carbide cut-off insert to an old brazed carbide tool that had lost it's tip.

I needed to shorten the insert and boy are they hard to cut, even with a grinder.

I then ground down a HSS blank to make a tiny boring bar to try and get the left side of the slot.

It sort of worked but was very slow and I still have the problem of cutting out the segments.

Is there a way to do this on a lathe?

What tools are normally used?

Brad93

Member

- Messages

- 19,444

- Location

- Essex, United Kingdom

Trepanning tool or a face grooving tool which is basically like a parting toolI’m trying to make an adapter so I can fit bristle blaster brushes in the polisher I'm playing with.

It a really tricky shape (I think) and I don't have a mill or the skills.

This is the part. The two half’s are identical and fit together nicely.

View attachment 254159

I don't have any alloy big enough, so built out some smaller round bar with tig.

View attachment 254160

I thought I could get in with an insert cut-off tool but there wasn’t enough back clearance so I brazed a carbide cut-off insert to an old brazed carbide tool that had lost it's tip.

I needed to shorten the insert and boy are they hard to cut, even with a grinder.

View attachment 254162

I then ground down a HSS blank to make a tiny boring bar to try and get the left side of the slot.

View attachment 254164

View attachment 254166

View attachment 254168

View attachment 254169

It sort of worked but was very slow and I still have the problem of cutting out the segments.

Is there a way to do this on a lathe?

What tools are normally used?

Agroshield

Member

- Messages

- 6,397

It sort of worked but was very slow and I still have the problem of cutting out the segments. Is there a way to do this on a lathe?

If you have a way to mount a powered spindle (die grinder, 1/4" laminate trimmer, etc.) on the cross slide, you can mill it out. The three jaws on a chuck are good for indexing the three slots.

Or mount the work on an angle plate/milling slide on the cross slide and use the lathe spindle to drive the tool.

Dcal

Member

- Messages

- 4,094

- Location

- Antrim Northern Ireland

THanks all for the tips and suggustions.

@Brad93 cheers for giving me the correct terminology, a search for trepanning got me a clip by my favourite YouTuber, Joe Pieczynski, that explains it really well.

I’m going to try and grind a HSS tool for the fun of it.

The slot is 14mm deep which won’t help but I might get away with it because it’s alloy and it will be a lot more robust than the boring bar.

@Agroshield I just made a bracket to mount a ¼ inch router to the lathe last night and it will take small milling cutters. There are some interrupted cuts I need to make that I can’t do on the lathe (I assume) so I think this will work for that.

It also cuts the slot far quicker. A lot noisier though.

I have a sort of milling attachment so that’s an option as well.

@Kram I have a rotary table but it’s far too big to mount on the lathe from both a weight and getting it on centre point of view. I have a nice vertical drill that will be man enough to take it so that’s is an option.

The slot doesn’t need to be too accurate, the brush is a loose fit in it, but the two half’s lock together which is probably beyond me so I think a redesign of that aspect is on the cards. Maybe two half circles instead of the three interlocking lugs on the original parts?

I’ve have been looking at small rotary tables but I should just put the money into a mill.

Biggest problem is I don’t have the room for even half the stuff I already have.

@Brad93 cheers for giving me the correct terminology, a search for trepanning got me a clip by my favourite YouTuber, Joe Pieczynski, that explains it really well.

I’m going to try and grind a HSS tool for the fun of it.

The slot is 14mm deep which won’t help but I might get away with it because it’s alloy and it will be a lot more robust than the boring bar.

@Agroshield I just made a bracket to mount a ¼ inch router to the lathe last night and it will take small milling cutters. There are some interrupted cuts I need to make that I can’t do on the lathe (I assume) so I think this will work for that.

It also cuts the slot far quicker. A lot noisier though.

I have a sort of milling attachment so that’s an option as well.

@Kram I have a rotary table but it’s far too big to mount on the lathe from both a weight and getting it on centre point of view. I have a nice vertical drill that will be man enough to take it so that’s is an option.

The slot doesn’t need to be too accurate, the brush is a loose fit in it, but the two half’s lock together which is probably beyond me so I think a redesign of that aspect is on the cards. Maybe two half circles instead of the three interlocking lugs on the original parts?

I’ve have been looking at small rotary tables but I should just put the money into a mill.

Biggest problem is I don’t have the room for even half the stuff I already have.

Agroshield

Member

- Messages

- 6,397

Rotary table on cross slide and mill the slots

That is an idea I have never heard and it is actually quite brilliant.

A milling slide on the cross slide gives you the third axis on the lathe and you calculate your operations using standard rectangular coordinates.

With a RT on the cross slide, you just calculate using polar coordinates. You would need to know relationship between lathe spindle centre height and RT centre height, but in principle, it is doable.

You might also have to stand at the back of the lathe to drive the RT as on a mill, the operating handle is usually on your right.

Dcal

Member

- Messages

- 4,094

- Location

- Antrim Northern Ireland

The woodruff key cutter arrived so had a go at cutting the keyway on the lathe.

The spindle I made was trashed during my earlier attempts so I decided to just fill the slot with braze and see how I got on.

I must say for £12 delivered from Cronos I was pleased with the result.

That allowed me to move on with my surface preperation tool build.

The spindle I made was trashed during my earlier attempts so I decided to just fill the slot with braze and see how I got on.

I must say for £12 delivered from Cronos I was pleased with the result.

That allowed me to move on with my surface preperation tool build.

Kram

Member

- Messages

- 8,386

- Location

- Sussex

Shrink fit was a failure but thats what big hammers are forI tried to braze but nowhere near hot enough with map. It'll do as is.. quick photo before I ruin it

Done!

Shrink fit did not last, threaded ring has started to pull out, I cant see any cracks.

Knocked it back into place.

I remember mapp did not have enough heat to braze this last time, might try with tig!

Brad93

Member

- Messages

- 19,444

- Location

- Essex, United Kingdom

TIG will distort it. The heat is too localised.View attachment 278738

Shrink fit did not last, threaded ring has started to pull out, I cant see any cracks.

Knocked it back into place.

I remember mapp did not have enough heat to braze this last time, might try with tig!