I was in the same boat. So I started to look at the older version of fusion and cross referenced the new version and wrote down where it was and what it was now called."Learn Fusion 360 or Die Tying..."

Yep, that's where I am at....

<edit> This is going to be tricky. Go to the "Create" tab. There isn't one.Software update has removed it. "Create a 2 point rectangle". Uh. No reference to that at all, not anywhere, not even in the Autodesk website where they are also showing you how to use the old software that you don't have...

It seems to "follow" this tutorial you would have to know in advance if your design is going to be a mesh, a form, sculpting or sketching for sheet, solid or... well you get the picture. I will give it a go but there does not appear to be a tutorial which you can follow, the buttons they point to are not there, the pages look different and on my dual monitor setup, Fusion hides everything you're doing if you flick back to the video.

I may die trying after all...

It's all still there. But it's been moved and or renamed.

But rest assured it makes very little sense when you start as it's not using usual windows logic.

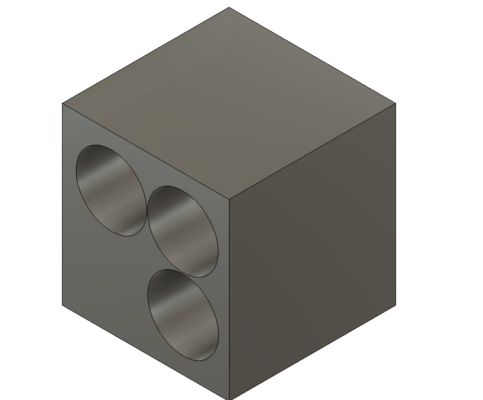

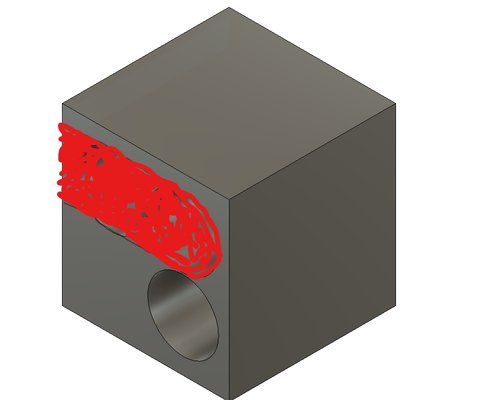

I found ignoring sketches. When I started helped me to alter basic shapes to get what I wanted. Now I need to learn how to apply a sketch to use as a tool to cut or alter the shapes I can create.

I am aware you should start using sketches but just could not get my head round it.