jpmillermatic

Member

- Messages

- 1,094

Ive decided to prep as many parts as I can before my new brake hardware arrives. Ive prepped the backing plates, axle U bolts and brackets and a few other bits and pieces. It took quite some time to bring the backing plates to life again as there are so many nooks and crannies. The passenger side was definitely worse than the drivers side...seems to be a standard issue with road salt building up on roadsides.....

anyway...here are a few pics of the progress......

backing plates are primed with galvanizing paint then finished with bedliner material for toughness...I already had a set of pads, and the drums are still good....but I needed all the springs, parking brake hardware, self adjusters, ect......

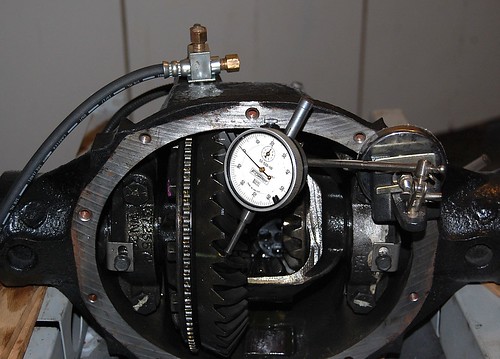

There are one or two adjustments I want to look into making....The "lash" adjustment between the main sprocket and pinion gear seems a bit too loose to me...and I have to switch the pinion output shaft's connector for the driveshaft so it fits my truck....

though its not actually going back together yet, I still feel Im making some progress....

thanks for lookin

JP

anyway...here are a few pics of the progress......

backing plates are primed with galvanizing paint then finished with bedliner material for toughness...I already had a set of pads, and the drums are still good....but I needed all the springs, parking brake hardware, self adjusters, ect......

There are one or two adjustments I want to look into making....The "lash" adjustment between the main sprocket and pinion gear seems a bit too loose to me...and I have to switch the pinion output shaft's connector for the driveshaft so it fits my truck....

though its not actually going back together yet, I still feel Im making some progress....

thanks for lookin

JP

Mitts are now available and can be washed and reused - dropping a clay bar spells its death knell.

Mitts are now available and can be washed and reused - dropping a clay bar spells its death knell.

.

.