You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Travel Tool Chest / Workbench

- Thread starter Dr.Al

- Start date

Dr.Al

Forum Supporter

- Messages

- 2,770

- Location

- Gloucestershire, UK

This morning, I took the masking tape off...

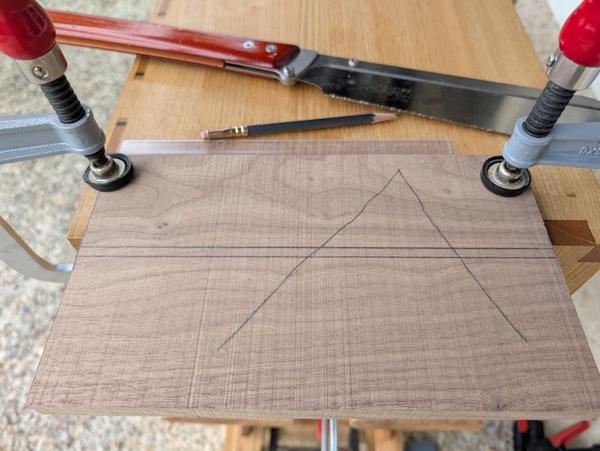

... and then put some more back on! The tape in the next picture is there just to give me an approximate guide for where to saw to when cutting the slots for the reinforcing splines. I used a bit of scrap wood that looked a sensible thickness as a reference, pushing the saw blade down onto the scrap piece and then moving saw and scrap back and forth together to cut the first side of the spline hole:

I then flipped the tray over and did the same again:

To take account of the saw kerf, I took a few plane shavings off the scrap wood. I then used the spline-to-be (an off-cut of the Sycamore I used as the base) as an additional spacer...

... allowing me to saw the other side of the spline hole:

To clean out the spline socket, I clamped the tray to the back of the tool chest (it's much too big for the maximum depth of the vice):

The waste could then be chiselled out with a 2 mm chisel:

Seven of the pockets went well. One ended up quite a bit bigger: I think I must have put the rib at the back of the saw on the spacer piece, resulting in it tilting down when sawing.

To deal with that, I just made all of the spline sockets at the bottom the same size as that one, resulting in four thick spline sockets at the bottom and four thinner ones at the top. Of course, that meant that I also needed some thicker splines.

Having retreated indoors due to the heat and humidity, I clamped the spacer piece in the vice and used the Dozuki to resaw it thinner:

The cut-off bit that had been resawn then got planed down to thickness, before chopping it up into bits:

After going round each pocket and making the ends of the spline sockets vertical (rather than parallel with the mitred corners: that means the splines can have square edges which is much easier) and generally tweaking everything until it looked good, glue was applied to the inside of the spline sockets and the faces of the splines and then they were shoved into place:

The little pen marks you can see in that image are to show which is the rough-sawn edge (one edge is planed smooth to help produce a clean fit against the corners of the socket).

Tomorrow (my last full day here) I'll hopefully get those splines cut off and planed smooth and then, all being well, the tray will be complete.

... and then put some more back on! The tape in the next picture is there just to give me an approximate guide for where to saw to when cutting the slots for the reinforcing splines. I used a bit of scrap wood that looked a sensible thickness as a reference, pushing the saw blade down onto the scrap piece and then moving saw and scrap back and forth together to cut the first side of the spline hole:

I then flipped the tray over and did the same again:

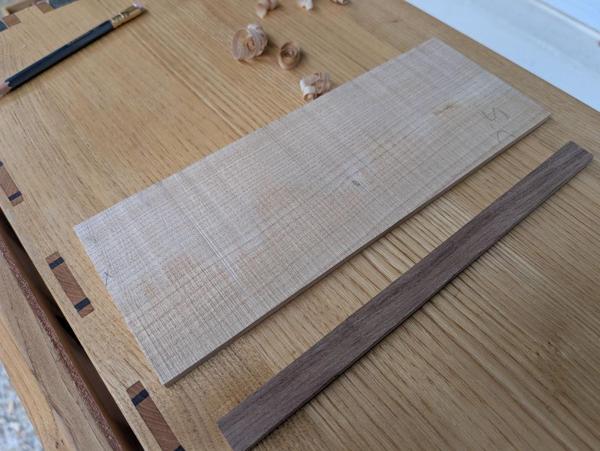

To take account of the saw kerf, I took a few plane shavings off the scrap wood. I then used the spline-to-be (an off-cut of the Sycamore I used as the base) as an additional spacer...

... allowing me to saw the other side of the spline hole:

To clean out the spline socket, I clamped the tray to the back of the tool chest (it's much too big for the maximum depth of the vice):

The waste could then be chiselled out with a 2 mm chisel:

Seven of the pockets went well. One ended up quite a bit bigger: I think I must have put the rib at the back of the saw on the spacer piece, resulting in it tilting down when sawing.

To deal with that, I just made all of the spline sockets at the bottom the same size as that one, resulting in four thick spline sockets at the bottom and four thinner ones at the top. Of course, that meant that I also needed some thicker splines.

Having retreated indoors due to the heat and humidity, I clamped the spacer piece in the vice and used the Dozuki to resaw it thinner:

The cut-off bit that had been resawn then got planed down to thickness, before chopping it up into bits:

After going round each pocket and making the ends of the spline sockets vertical (rather than parallel with the mitred corners: that means the splines can have square edges which is much easier) and generally tweaking everything until it looked good, glue was applied to the inside of the spline sockets and the faces of the splines and then they were shoved into place:

The little pen marks you can see in that image are to show which is the rough-sawn edge (one edge is planed smooth to help produce a clean fit against the corners of the socket).

Tomorrow (my last full day here) I'll hopefully get those splines cut off and planed smooth and then, all being well, the tray will be complete.

Dr.Al

Forum Supporter

- Messages

- 2,770

- Location

- Gloucestershire, UK

This morning, I started by sawing off the bulk of the waste with the Dozuki. This was done with one hand holding the tray down on top of the chest: it didn't feel like it needed clamping at all.

That left a rough finish and a millimetre or two of waste to get rid of.

That got pared flush with a chisel...

... and then I took a light pass with a smoothing plane:

That's it for now. I expect I'll end up doing a bit more smoothing planing when I get home: it's bound to get the odd little knock in transit. Once I'm home, I'll do any final tidying that I think is necessary and then apply some oil.

That left a rough finish and a millimetre or two of waste to get rid of.

That got pared flush with a chisel...

... and then I took a light pass with a smoothing plane:

That's it for now. I expect I'll end up doing a bit more smoothing planing when I get home: it's bound to get the odd little knock in transit. Once I'm home, I'll do any final tidying that I think is necessary and then apply some oil.

arther dailey

Member

- Messages

- 6,987

- Location

- England

apart from the obvious skill involved it is loverly to see the wood after a truly sharp chisel has been used , pleasure to see.Over the last couple of days we've been out and about in the Pyrenees. The scenery round here is beautiful and we even got to see a golden eagle up extremely close when it flew across in front of us. With all that, I didn't do any more on the box until this morning.

Before doing anything on the box itself, I decided to fix the drawer supports in place permanently:

I really like having the three most useful drawers lying on the bench stretchers so I'm happy to commit to the screw holes now (the supports were originally just held in place with double-sided tape).

Returning to the box, the first thing I did today was chisel the mitred corners using the mitre guide I prepared in the last instalment:

I then relieved all the inside corners of the tails in order to help the joints go together easily:

For the back of the chest, I didn't have any Sycamore that was big enough, so I pulled out a bit of 6 mm ish rough sawn Sweet Chestnut:

After cutting it in half, I planed that on both sides, resulting in a piece about 5 mm thick:

I could then plough some matching grooves and it was nice to be able to use the little plough plane that I found a spot for in one of the drawers. It took a while to get everything set-up: various stops clamped to the bench and the assembly of the plough plane itself, which is packed in pieces in the tool chest. However, once everything was set up, ploughing the four grooves was completed very quickly:

The four side pieces with their grooves:

I'm planning to make this into a box with two drawers. I've brought a piece of 16 mm-ish thick American Black Walnut with me to act as the drawer fronts. Unlike the previous drawer box (which had the dividing "shelf" hidden behind a lip on the lower drawer), I've decided to make the "shelf" visible but to try to grain match it to the drawer fronts. To that end, I marked up a thin-ish strip in the middle of the plank:

After cross-cutting to length, I reinforced the pencil marks...

... and (after taking a deep breath as I was a bit nervous about sawing skew-whiff), I ripped the board into three pieces with the Dozuki:

I was rather pleased with how that went:

The other half of the Sweet Chestnut plank will be used for most of the shelf, but the thinner bit of Walnut will act as a trim to (hopefully) make it look better. Without bothering to try to plane the face sides down at all, I just planed the joining edge straight and square on the two pieces:

Glue was applied...

... and then I got a bit carried away with masking tape:

Once the glue has dried, I'll plane the faces and then trim it to the final size. I'm not going to cut the housing in the case sides until I've planed the shelf to thickness; that way I can be more confident of getting a snug housing joint.

At this point, I realised that I won't be able to finish this drawer box while I'm in France. I hadn't planned what I was going to make very carefully for this trip, just chucking a load of wood in a bag and assuming I'd figure it out when I got here. I did, however, put a load of thin off-cuts of Sycamore in, thinking they would be good for drawer sides. They will be good for drawer sides, but I've made this box quite big as I wanted relatively deep drawers and as such the Sycamore pieces are too narrow to be used for the sides of the two drawers:

I could make the top drawer narrower than the bottom one and continue to make the top drawer with that Sycamore (and sort out the bottom drawer when I get back home) or I could make them both equal and sort both drawers out when I get home. Either way, the box won't be finished while I'm here, but that doesn't really matter - it's still nice to have some woodworking tasks to get on with. I'll have a rummage through the rest of the wood that I brought with me and I may be able to use that Sycamore for something else instead, or alternatively just make (or start making) a completely different box altogether. This is the downside of not planning the boxes I'm going to make in advance!

Dr.Al

Forum Supporter

- Messages

- 2,770

- Location

- Gloucestershire, UK

I'm back home again now. I haven't had a lot of time free to finish off the two boxes, but I have applied two coats of Mike's Magic Mix to the mitred tray:

I think this tray is going to become a home for the (three) remote controls in the lounge, which currently live in a rather shabby wicker basket.

I think this tray is going to become a home for the (three) remote controls in the lounge, which currently live in a rather shabby wicker basket.

Dr.Al

Forum Supporter

- Messages

- 2,770

- Location

- Gloucestershire, UK

Since getting back, I haven't managed to spend much time on the drawer box, but I did have a rummage around to try to find some material for the drawer sides. The only stuff that looked promising was in the form of a (somewhat excessively) large plank of sweet chestnut:

That's obviously far too much wood for the sides and back of two drawers, so I started by getting the big Ryoba out and chopping the end off:

I then started ripping it to (a bit over-) width using the big Ryoba but it was feeling hard work so I swapped to the little one and that went much quicker:

The big Ryoba was the one that I used to use for resawing before I bought my bandsaw, so those rip teeth have had a fairly hard life; I suspect they're not as sharp as they once were.

With the piece cut a bit smaller, I could plane both faces...

... and then plane both edges, making sure one edge was square to one face and the other square to the other:

I could then use the face/edge pairs as references against the bandsaw fence and table and chop the plank into three bits, two with one planed face and one with none:

Those pieces should give me plenty of stock for the sides and back of the drawers. The next job will be to plane them all round, but I expect that'll be next weekend, which at least has the advantage of allowing them a bit of post-resaw time to bend/twist or whatever else they want to do before I plane them.

That's obviously far too much wood for the sides and back of two drawers, so I started by getting the big Ryoba out and chopping the end off:

I then started ripping it to (a bit over-) width using the big Ryoba but it was feeling hard work so I swapped to the little one and that went much quicker:

The big Ryoba was the one that I used to use for resawing before I bought my bandsaw, so those rip teeth have had a fairly hard life; I suspect they're not as sharp as they once were.

With the piece cut a bit smaller, I could plane both faces...

... and then plane both edges, making sure one edge was square to one face and the other square to the other:

I could then use the face/edge pairs as references against the bandsaw fence and table and chop the plank into three bits, two with one planed face and one with none:

Those pieces should give me plenty of stock for the sides and back of the drawers. The next job will be to plane them all round, but I expect that'll be next weekend, which at least has the advantage of allowing them a bit of post-resaw time to bend/twist or whatever else they want to do before I plane them.

Dr.Al

Forum Supporter

- Messages

- 2,770

- Location

- Gloucestershire, UK

I love the fact you basically do 99% of your woodwork by hand. Personally I'm all for making my life easier with power tools but the respect I have for those who almost exclusively work by hand is huge!

I used to do it mostly with power tools but got fed up with the noise and dust and hence the fact I spent so much of the garage time wearing a face mask, ear defenders and dust mask. For me it's more about the process than the end result anyway, so if it takes a bit longer but the process is enjoyable then that's a good thing, especially if I'm also learning new skills rather than just relying on machinery. I still see the act of selling my table saw as one of the best things I ever did.

Dr.Al

Forum Supporter

- Messages

- 2,770

- Location

- Gloucestershire, UK

I want one now, but it would never be as good as yours

Where do you get your timber?

Mostly from Wentwood Timber Centre near Chepstow. They only stock native timbers (and mostly stuff from within not many miles of Chepstow) but they seem to be consistently substantially cheaper than anywhere else I've been. The timber yard / showroom is in a lovely location too! Non-native stuff (e.g. American Black Walnut) has generally come from Yandles in Somerset, although there are a few others I've been too when in the area (e.g. Tyler Hardwoods near Hungerford/Marlborough and Surrey Timbers in Guildford). None anywhere near Wirral I'm afraid.

Dr.Al

Forum Supporter

- Messages

- 2,770

- Location

- Gloucestershire, UK

It's been a very long time since I last posted in this build thread. We left the action a little over two months ago with me having chopped the end off a big lump of sweet chestnut and chopped it up into pieces.

A few days later, I spent a little time with a couple of planes to clean up the faces of those pieces and bring them to an even thickness:

While I was at it, I also planed the inside faces of the drawer fronts: these faces will be used as references when making the drawers:

I didn't want to plane the outside faces too early as they're covered in pencil marks reminding me what goes where. I'm glad I didn't as there was then a two month gap where I didn't do anything on the drawer box.

Today, I dug out a bit of sycamore to use as the bases for the drawers and planed its outside faces:

I then fed it through the bandsaw...

... and then planed the sawn faces of the two outside pieces down to about 4 mm thickness:

After labelling and drawing lines on the sweet chestnut pieces that will become the drawer sides and back, I clamped them to the edge of the bench and sawed slightly oversize with the Dozuki:

You'll notice the mix of clamps in that photo. I generally prefer the red handled quick clamp and would typically use two of them in a situation like this, but the pitch of holes in my bench was almost exactly wrong and the second clamp didn't have the right reach so I had to use the Gramercy hold-fast instead.

While I was at it, I also ripped the drawer fronts to slightly-over width, again needing to use the hold-fast for the same reason:

Finally, I chopped the back and side pieces up into individual pieces. I'd considered planing the edges while it was one long plank but decided it would be simpler to just chop it up now and handle each piece on its own:

That gives me this pile of pieces out of which I need to make two drawers.

I've got a spare length of the sweet chestnut, but if I make any mistakes with the other pieces I'll be most disgruntled!

A few days later, I spent a little time with a couple of planes to clean up the faces of those pieces and bring them to an even thickness:

While I was at it, I also planed the inside faces of the drawer fronts: these faces will be used as references when making the drawers:

I didn't want to plane the outside faces too early as they're covered in pencil marks reminding me what goes where. I'm glad I didn't as there was then a two month gap where I didn't do anything on the drawer box.

Today, I dug out a bit of sycamore to use as the bases for the drawers and planed its outside faces:

I then fed it through the bandsaw...

... and then planed the sawn faces of the two outside pieces down to about 4 mm thickness:

After labelling and drawing lines on the sweet chestnut pieces that will become the drawer sides and back, I clamped them to the edge of the bench and sawed slightly oversize with the Dozuki:

You'll notice the mix of clamps in that photo. I generally prefer the red handled quick clamp and would typically use two of them in a situation like this, but the pitch of holes in my bench was almost exactly wrong and the second clamp didn't have the right reach so I had to use the Gramercy hold-fast instead.

While I was at it, I also ripped the drawer fronts to slightly-over width, again needing to use the hold-fast for the same reason:

Finally, I chopped the back and side pieces up into individual pieces. I'd considered planing the edges while it was one long plank but decided it would be simpler to just chop it up now and handle each piece on its own:

That gives me this pile of pieces out of which I need to make two drawers.

I've got a spare length of the sweet chestnut, but if I make any mistakes with the other pieces I'll be most disgruntled!

Dr.Al

Forum Supporter

- Messages

- 2,770

- Location

- Gloucestershire, UK

I managed a couple of hours on the box this afternoon. I started by dimensioning the drawer fronts to be a snug fit end-to-end and a loose fit top-to-bottom in the carcase:

I then used the shooting board to bring the back to the same size:

I also used it to bring the sides to the same height (width) but didn't do anything about the length of them for now. Finally, I planed the drawer fronts to what will be their final thickness (about 14 mm). I could then start marking out and sawing the tails at the front end of the side boards:

Three little chisels then finished the tails:

I haven't cut the tails on the backs of these boards yet as they're still too long. Once the first joints are done, I'll figure out how long they need to be.

I marked the sockets in the usual way:

You'll notice that I'm keeping my life simple by not trying to narrow pins on the drawers. It was an interesting exercise to do it on the carcase but I wanted an easy life this time. The marked up sockets:

This is the first one done:

At that point the darkness was feeling awkward with seeing what I was doing (despite the myriad of cool white LED lighting in the garage) and it was getting chilly so I decided to retire to the house for the evening. More tomorrow hopefully.

I then used the shooting board to bring the back to the same size:

I also used it to bring the sides to the same height (width) but didn't do anything about the length of them for now. Finally, I planed the drawer fronts to what will be their final thickness (about 14 mm). I could then start marking out and sawing the tails at the front end of the side boards:

Three little chisels then finished the tails:

I haven't cut the tails on the backs of these boards yet as they're still too long. Once the first joints are done, I'll figure out how long they need to be.

I marked the sockets in the usual way:

You'll notice that I'm keeping my life simple by not trying to narrow pins on the drawers. It was an interesting exercise to do it on the carcase but I wanted an easy life this time. The marked up sockets:

This is the first one done:

At that point the darkness was feeling awkward with seeing what I was doing (despite the myriad of cool white LED lighting in the garage) and it was getting chilly so I decided to retire to the house for the evening. More tomorrow hopefully.

Dr.Al

Forum Supporter

- Messages

- 2,770

- Location

- Gloucestershire, UK

I only had an hour out in the garage this morning but I've done the rest of the half-lap dovetails:

I noticed after doing them that I'd been a little dense and arranged two of the side planks such that they will be planed back-to-front instead of front-to-back. They're slightly oversize at the moment so that I can plane the sides down to match the width of the front pieces. Having arranged two of them that way round I'll have two options I think. Either I'll clamp some sort of off-cut to the front of the box so that it supports the trailing edge, or I'll plane with a high angle plane and hope that is sufficient to prevent tear-out. Sweet Chestnut is quite forgiving compared to, say, Ash, so I'm leaning towards the latter for simplicity.

I've got a few errands to run now, but hopefully I'll get some time this afternoon to shorten the side boards to length and then cut the rear dovetails.

I noticed after doing them that I'd been a little dense and arranged two of the side planks such that they will be planed back-to-front instead of front-to-back. They're slightly oversize at the moment so that I can plane the sides down to match the width of the front pieces. Having arranged two of them that way round I'll have two options I think. Either I'll clamp some sort of off-cut to the front of the box so that it supports the trailing edge, or I'll plane with a high angle plane and hope that is sufficient to prevent tear-out. Sweet Chestnut is quite forgiving compared to, say, Ash, so I'm leaning towards the latter for simplicity.

I've got a few errands to run now, but hopefully I'll get some time this afternoon to shorten the side boards to length and then cut the rear dovetails.

Dr.Al

Forum Supporter

- Messages

- 2,770

- Location

- Gloucestershire, UK

Weird. They appear fine here. They're hosted on my website (to make it easy to share on multiple forums). Can you access https://www.cgtk.co.uk ?That's odd the pictures aren't loading

Dr.Al

Forum Supporter

- Messages

- 2,770

- Location

- Gloucestershire, UK

When I made it out to the workshop this afternoon, I started on the remaining joints for the drawer sides. With the drawer sides dry fitted to the fronts the drawer won't go into the box (as I still need to plane the sides down flush with the front and back, which I'll do after gluing). Instead, I got a scrap of ash and shoved it into the carcase. I could then knife a line on it where it met the front of the walnut piece:

That ash piece could then be used to transfer the depth onto the side pieces:

The ends got sawn off...

... and then shot to the transferred knife line:

A little bit of sawing and chiselling later (done in the same way I usually do so I didn't bother with photos) and all the dovetails are done:

One of the advantages of half-lap dovetails (as on the drawer front joints) is that, if you think about it beforehand, you can arrange the ploughed groove for the drawer base to come out in the chiselled out pocket. In combination with a mitred dovetail at the back you can then plough all the grooves with a plough plane.

However, if you're a bit frazzled in the run up to Christmas and don't think about it in advance, then the best place for a groove ends up being in the pin area rather than the tail area. Ploughing the grooves in the sides is still easy...

... however, the front and back need to have stopped grooves. I could have still done a mitred dovetail at the back but given I was doing a stopped groove at the front I figured I just do the same at the back. I started by marking the two sides of the groove with a pair of marking gauges:

I then chopped down on the shoulder line with a 4 mm chisel and then used the router plane to work down until the groove was deep enough:

Finally, I extended the groove out into the pin with the 4 mm chisel (I didn't do the full length in one go as I didn't want to risk blowing out the end of the groove):

The bases still needed cutting to size, which I did with saw and shooting board:

I could then do a dry fit:

If I were starting again I think I'd reduce the thickness of the sides and back a bit more (they're about 8 to 9 mm from memory but for such a small drawer they could easily have been smaller), but I'm not going to start again so they'll have to do!

I'm going to do something similar to a previous drawer box for the pull: an indent with a knob set into that indent. I'm aiming for a fairly "rustic" finish on the indent. I started by drilling a blind 4 mm hole with the pillar drill. I then inserted a 35 mm Forstner bit into the central hole and twisted it gently by hand to give me a diameter guide:

The first pass was done with a fairly big gouge. That left a fairly nice finish and I'm sure I could have cleaned it up with a few more light cuts:

However, cleaning it up would be a bit pointless given I then wanted to get a rippled finish with a smaller gouge:

Before gluing the box together, I gave the drawer fronts a quick squirt with some water to check I was happy with the look:

I then glued it together with this stuff, warmed in a bath of hot water:

I didn't get any photos of it glued and clamped together and I can't be bothered to go back out and take another photo so you'll have to use your imagination!

That ash piece could then be used to transfer the depth onto the side pieces:

The ends got sawn off...

... and then shot to the transferred knife line:

A little bit of sawing and chiselling later (done in the same way I usually do so I didn't bother with photos) and all the dovetails are done:

One of the advantages of half-lap dovetails (as on the drawer front joints) is that, if you think about it beforehand, you can arrange the ploughed groove for the drawer base to come out in the chiselled out pocket. In combination with a mitred dovetail at the back you can then plough all the grooves with a plough plane.

However, if you're a bit frazzled in the run up to Christmas and don't think about it in advance, then the best place for a groove ends up being in the pin area rather than the tail area. Ploughing the grooves in the sides is still easy...

... however, the front and back need to have stopped grooves. I could have still done a mitred dovetail at the back but given I was doing a stopped groove at the front I figured I just do the same at the back. I started by marking the two sides of the groove with a pair of marking gauges:

I then chopped down on the shoulder line with a 4 mm chisel and then used the router plane to work down until the groove was deep enough:

Finally, I extended the groove out into the pin with the 4 mm chisel (I didn't do the full length in one go as I didn't want to risk blowing out the end of the groove):

The bases still needed cutting to size, which I did with saw and shooting board:

I could then do a dry fit:

If I were starting again I think I'd reduce the thickness of the sides and back a bit more (they're about 8 to 9 mm from memory but for such a small drawer they could easily have been smaller), but I'm not going to start again so they'll have to do!

I'm going to do something similar to a previous drawer box for the pull: an indent with a knob set into that indent. I'm aiming for a fairly "rustic" finish on the indent. I started by drilling a blind 4 mm hole with the pillar drill. I then inserted a 35 mm Forstner bit into the central hole and twisted it gently by hand to give me a diameter guide:

The first pass was done with a fairly big gouge. That left a fairly nice finish and I'm sure I could have cleaned it up with a few more light cuts:

However, cleaning it up would be a bit pointless given I then wanted to get a rippled finish with a smaller gouge:

Before gluing the box together, I gave the drawer fronts a quick squirt with some water to check I was happy with the look:

I then glued it together with this stuff, warmed in a bath of hot water:

I didn't get any photos of it glued and clamped together and I can't be bothered to go back out and take another photo so you'll have to use your imagination!

Dr.Al

Forum Supporter

- Messages

- 2,770

- Location

- Gloucestershire, UK

This morning I've been cleaning up the sides and back of the boxes. With the grain direction being "wrong" on two of the sides, I decided to use a backer board rather than a high angle plane, with the box held in the two-screw "Moxon"-style vice in my Portable Workbench:

Where there was a tiny bit of glue squeeze-out still visible around the joints I used a card scraper to tidy it up locally:

The back got a chamfer with my block plane and a light pass with a card scraper was enough to bring everything flush:

The rims were mostly flush with one another but in the one or two corners where I could feel a slight ridge, I again used the card scraper:

Does anyone else chamfer internal corners with a card scraper?

I ended up using the card scraper to break most of the edges (internal and external) as it was easier to just keep that in my hand and work round everywhere.

For test fitting, I added a bit of masking tape with a big doubled-over section on the top:

I could then shove the drawers into their holes safe in the knowledge that I'd be able to pull them back out again!

After taking that photo, I also chamfered around all the edges of the fronts of the drawers: that makes the expansion gap above the bottom drawer less obvious I think.

The next job is to tidy the bench up and then get the lathe out to turn the drawer pulls.

I also need to decide what (if anything) to do about feet. On the last drawer box I made, I stuck some bits of maple on the bottom (see this photo). I'd be interested in opinions as to whether I should do the same (with walnut feet) on this one or just to leave the box sitting flat on its base.

Where there was a tiny bit of glue squeeze-out still visible around the joints I used a card scraper to tidy it up locally:

The back got a chamfer with my block plane and a light pass with a card scraper was enough to bring everything flush:

The rims were mostly flush with one another but in the one or two corners where I could feel a slight ridge, I again used the card scraper:

Does anyone else chamfer internal corners with a card scraper?

I ended up using the card scraper to break most of the edges (internal and external) as it was easier to just keep that in my hand and work round everywhere.

For test fitting, I added a bit of masking tape with a big doubled-over section on the top:

I could then shove the drawers into their holes safe in the knowledge that I'd be able to pull them back out again!

After taking that photo, I also chamfered around all the edges of the fronts of the drawers: that makes the expansion gap above the bottom drawer less obvious I think.

The next job is to tidy the bench up and then get the lathe out to turn the drawer pulls.

I also need to decide what (if anything) to do about feet. On the last drawer box I made, I stuck some bits of maple on the bottom (see this photo). I'd be interested in opinions as to whether I should do the same (with walnut feet) on this one or just to leave the box sitting flat on its base.

Depends on where its going in my opinion.I'd be interested in opinions as to whether I should do the same (with walnut feet) on this one or just to leave the box sitting flat on its base.

The little feet leave a nice shadow gap between the box and what its sitting on, but at the same time that can look at bit wierd on a small item if its at eye level.

Personally I'd probably go with feet if your going to be looking down on it, but no feet if its going to live at eye level.

Fat lot of help I am.

Dr.Al

Forum Supporter

- Messages

- 2,770

- Location

- Gloucestershire, UK

The first stage in making the drawer pulls was to clear the bench and set up the lathe. I also installed a newly acquired poly-backed cotton dust sheet to hang over the tool wall and save me a bit of dusting later:

Some off-cuts of Sycamore were used for the pulls. This was the first one:

I ended up making four of them. They all went quite smoothly, but the first two were a bit different in size/shape so I made a couple more and then picked the closest two:

The chosen two got glued and clamped in place:

While the drawer pulls are gluing, I brought the carcase in and put it in my new 3D printer (which has a laser cutter option). The box is getting near the size limit for the printer:

My logo has now been engraved onto the back of the box:

The next job will be to oil the box and the drawers and then I think I'm going to stick some leather feet to the bottom of it.

Some off-cuts of Sycamore were used for the pulls. This was the first one:

I ended up making four of them. They all went quite smoothly, but the first two were a bit different in size/shape so I made a couple more and then picked the closest two:

The chosen two got glued and clamped in place:

While the drawer pulls are gluing, I brought the carcase in and put it in my new 3D printer (which has a laser cutter option). The box is getting near the size limit for the printer:

My logo has now been engraved onto the back of the box:

The next job will be to oil the box and the drawers and then I think I'm going to stick some leather feet to the bottom of it.