jordhandson

Member

- Messages

- 1,430

- Location

- Dorset

Through coolant adapters I have a bucket of iso 40 ones , which are too tidley for my manly machinery

Ha ha yeh be wasted on my plodder

Through coolant adapters I have a bucket of iso 40 ones , which are too tidley for my manly machinery

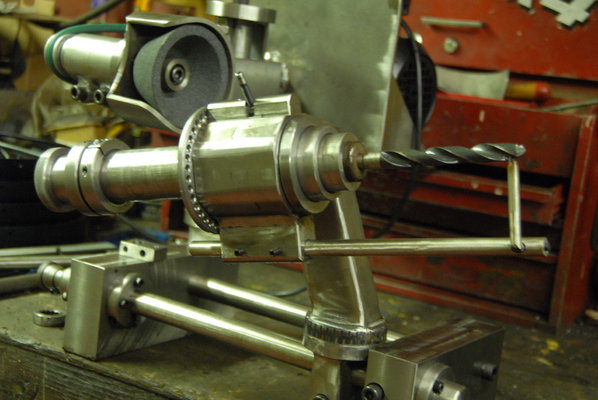

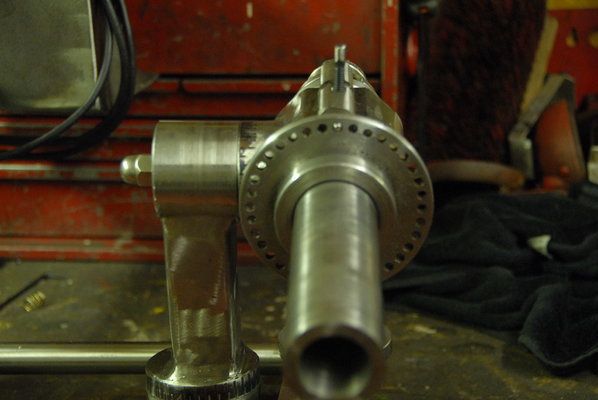

just to mention something on mine before you go to far mine has a way to do the flutes down the mill end

and if you look at the extras i can also use 2-3-4-5-6 flutes to sharpen them up by twisting

it also has a blade so it slots into the mill spiral and then you twist it to sharpen the flute edges down the end mill

just incase you decide to weld lock alot when really you shouldnt but allow it to move on the round bar

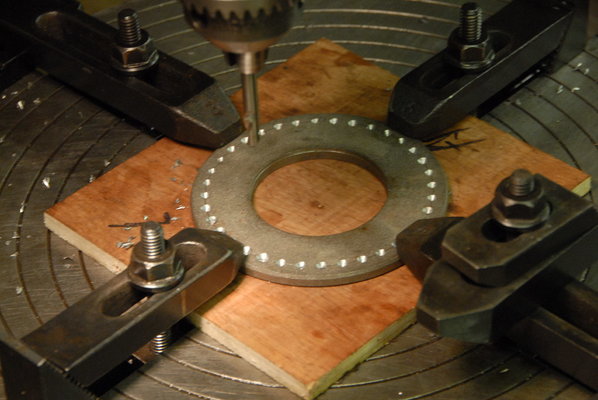

View attachment 210003

just to mention something on mine before you go to far mine has a way to do the flutes down the mill end

and if you look at the extras i can also use 2-3-4-5-6 flutes to sharpen them up by twisting

it also has a blade so it slots into the mill spiral and then you twist it to sharpen the flute edges down the end mill

just incase you decide to weld lock alot when really you shouldnt but allow it to move on the round bar

View attachment 210003

just to mention something on mine before you go to far mine has a way to do the flutes down the mill end

and if you look at the extras i can also use 2-3-4-5-6 flutes to sharpen them up by twisting

it also has a blade so it slots into the mill spiral and then you twist it to sharpen the flute edges down the end mill

just incase you decide to weld lock alot when really you shouldnt but allow it to move on the round bar

View attachment 210003

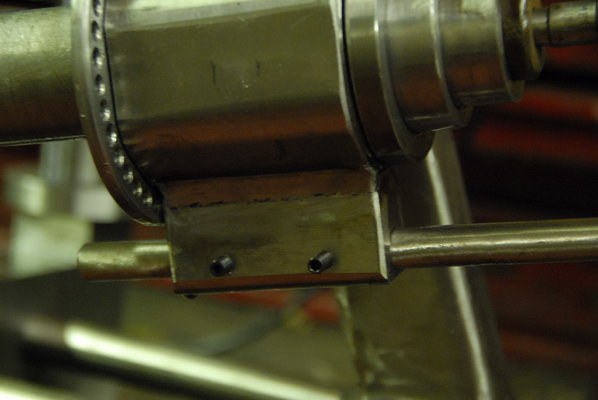

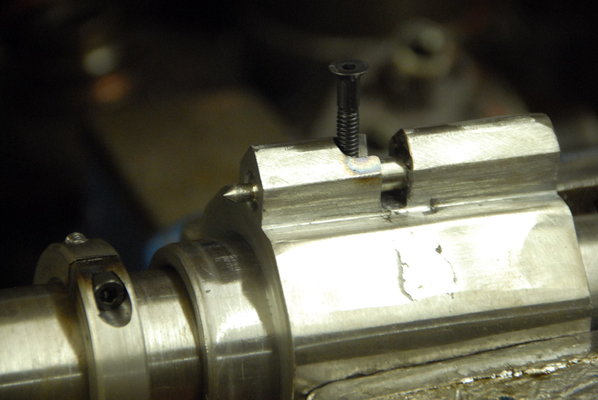

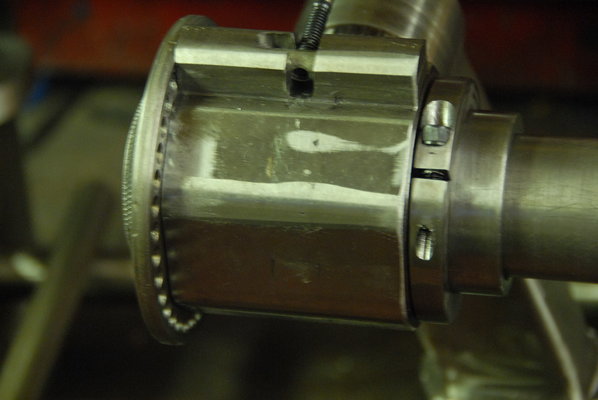

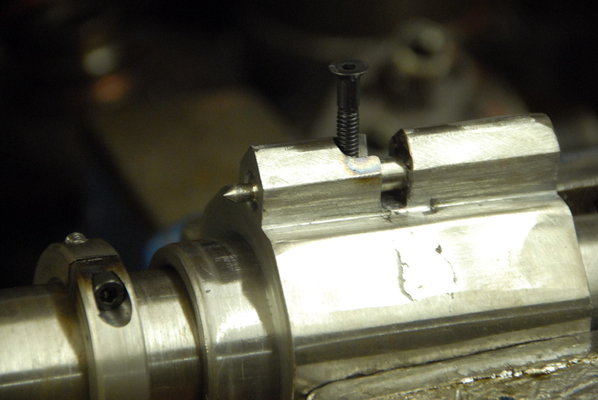

I am not weld locking anything its difficult to explain, the slot along the side of the tool holder allows the tool holder to slide forwards and back, and the clamp round the indexing tube stops the indexing tube sliding out.

I am not weld locking anything its difficult to explain, the slot along the side of the tool holder allows the tool holder to slide forwards and back, and the clamp round the indexing tube stops the indexing tube sliding out.

And I only opened the one containing the motor [among other bits] to make sure it worked.

And I only opened the one containing the motor [among other bits] to make sure it worked.

@jordhandson Reading your progress and the good work your doing, I feel very guilty knowing I have a Quorn machine presently sitting in three boxes, two of which I haven't even opened......And I only opened the one containing the motor [among other bits] to make sure it worked.

So many projects means that it'll be some time before I unpack it all. I don't want bits of it scattered around and neglected while I have to attend to something else.

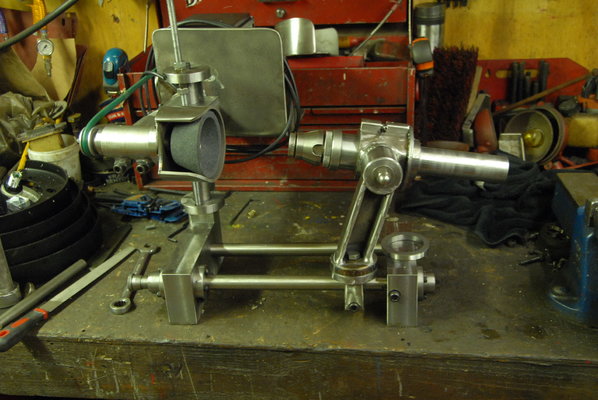

. Tools like I need now take priority, the tool grinder is needed like yesterday otherwise I am going to have to many bits that need sharpening, and that's when my head gets

. Tools like I need now take priority, the tool grinder is needed like yesterday otherwise I am going to have to many bits that need sharpening, and that's when my head gets  bogged down.

bogged down.Miss understanding there gaz,I am not weld locking anything its difficult to explain, the slot along the side of the tool holder allows the tool holder to slide forwards and back, and the clamp round the indexing tube stops the indexing tube sliding out.

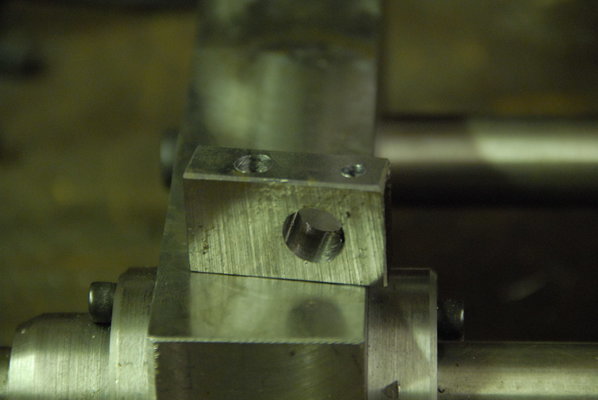

mines just a round bar with a bar stuck out and dosnt have a slot in it

this allows me to use the spiral feature when doing the flutes on the milling end mill

mine will have the option of locking into the indexing head vie a turn screw, or loosen the turn screw then allowing it to travel to do the flutes, or any other thing that needs forwards or backward adjustments

mine will have the option of locking into the indexing head vie a turn screw, or loosen the turn screw then allowing it to travel to do the flutes, or any other thing that needs forwards or backward adjustments

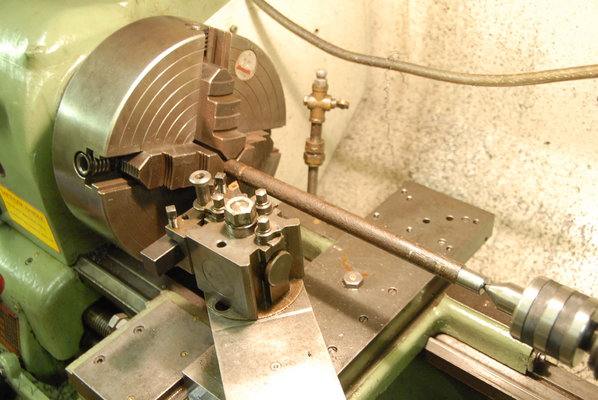

use your bar below the tool post itself as mine connects there as its out of the way and is solid enough

View attachment 210084

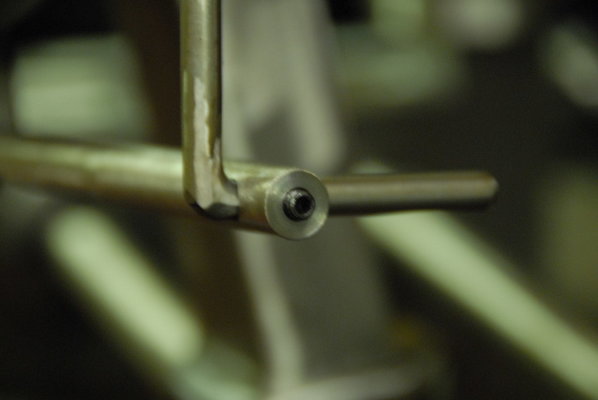

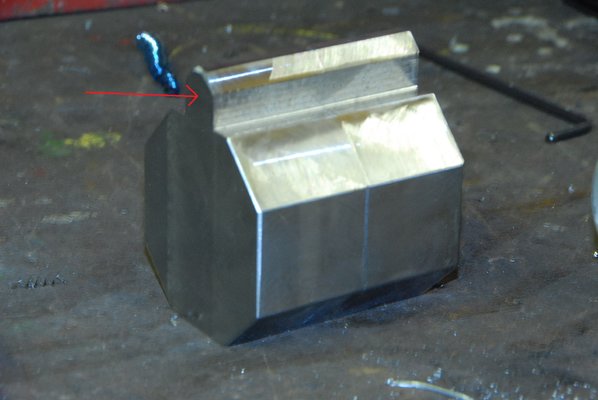

My pal uses this set-up but says it's a bit of a faff - he doesn't do much milling but says it does work

View attachment 210085