hi, redwine your work looks grate good job. you said you are using 20g and a Clarke what gas are you using and what settings on the welder i have the same welder and have a discovery with lots to be done

hi, redwine your work looks grate good job. you said you are using 20g and a Clarke what gas are you using and what settings on the welder i have the same welder and have a discovery with lots to be done  i have been practicing on some 3mm plate and now have some 20g and was just wondering what settings you was using thanks mate keep up the good work

i have been practicing on some 3mm plate and now have some 20g and was just wondering what settings you was using thanks mate keep up the good work

Colin

Colin

My MIG, as you say is a Clarke 135te. When i am butt welding 20g i am using the lowest power setting. (1 min ) with a wire speed of 6.5.(0.6 wire by the way) As for the gas, I am using BOC Argoshield light and depending on the wind, I am set at between 12lpm and 14lpm. I try and shield myself as best as I can from the light wind with my fishing umbrella. I have found that the slightest breeze makes a big difference. I would add that the closer the match between the 2 pieces when butting together the better.

My MIG, as you say is a Clarke 135te. When i am butt welding 20g i am using the lowest power setting. (1 min ) with a wire speed of 6.5.(0.6 wire by the way) As for the gas, I am using BOC Argoshield light and depending on the wind, I am set at between 12lpm and 14lpm. I try and shield myself as best as I can from the light wind with my fishing umbrella. I have found that the slightest breeze makes a big difference. I would add that the closer the match between the 2 pieces when butting together the better. Good luck with the Discovery by the way and remember, just as you think you wish you hadn't started don't give up it will come.

Good luck with the Discovery by the way and remember, just as you think you wish you hadn't started don't give up it will come.

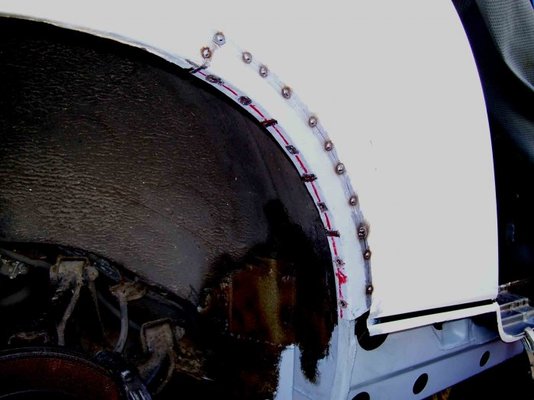

Managed to get a bit of inner wheelarch welded in though.

Managed to get a bit of inner wheelarch welded in though. This will let me weld in the outer sill return on to good metal, which in turn will allow me to fit and weld front outer sill.

This will let me weld in the outer sill return on to good metal, which in turn will allow me to fit and weld front outer sill.

I have looked at it, as you say with regards to filling and sanding back. Fortunately the distortion has gone in wards, so if I build up with filler as you say and use a large flat sanding block I should get away with it.

I have looked at it, as you say with regards to filling and sanding back. Fortunately the distortion has gone in wards, so if I build up with filler as you say and use a large flat sanding block I should get away with it.