Onoff

In the land of the unfinished project I am King!

- Messages

- 13,250

- Location

- Sevenoaks, UK

Are the flow rate test files in Orca or maker world?

From the Orca slicer.

Are the flow rate test files in Orca or maker world?

Tried the 3D printed jacking pad in the two poster earlier. Did it when I'd finished the oil change and just put one arm under the sill so only lifted "a quarter" of the weight.....'ish.

It appeared to deform a bit but all sprang back with no damage.

Incidentally the TPU is listed as Shore 95A. The pads you can buy appear to be Shore 80 so in fact softer.

I thought my Neptune 3 MAX was bigNow this is a silly large printer.

Elegoo OrangeStorm Giga - Best Large FDM 3D Printer 2024

Discover the Elegoo OrangeStorm Giga, the best large 3D printer of 2024 at an affordable price. Enjoy multi-nozzle FDM printing for all your big projects now.uk.elegoo.com

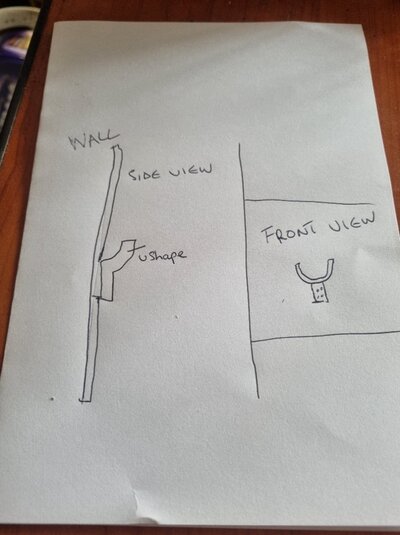

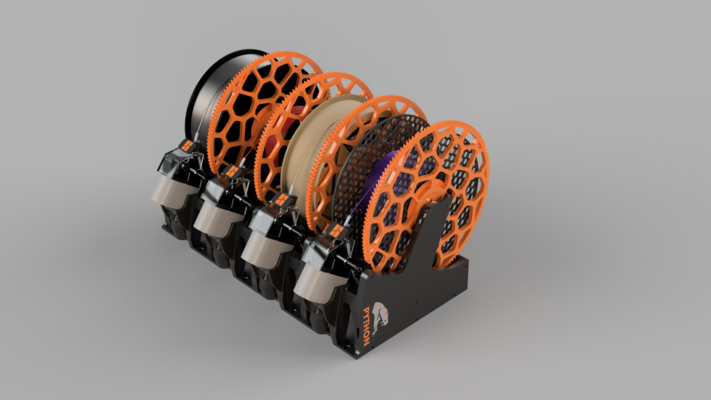

I would have printed something but I cant find an STL . I am after a spool holder that screws to the wall. Its probably on the principle of an angle grinder holder where a curved holder allows a spool to be placed flat on the wall. In my case it cant be totally flush as the Python spool holders have a bearing on both ends. The real awkward part is the spool holder has a large gear attached so you cant use a strip rack where the rolls all side side ways.View attachment 512953View attachment 512954

Difficult to describe but I want something that allows the spool to sit like the first photo.

Imagine the second photo my arm is under the spool and screwed to the wall/cupboard. Allowing the the large gear to sit over the front of the spool holder.

Does anyone know of such a spool holder...

No even more simple than that. The u shape would step out from the wall to support the spool.haven’t seen one

do you need something like a big U shape, with a a gap in the top of each of the legs of the U for the bearings to drop into?

what's the gear for? - rewind with colour/material changing?

Sounds like you need a large dove tail like a 20mm wide slice of this lathe slide but the dove tail is angled V like so it holds the spool lip just below the centre line on a tangent? Would certainly be quicker to print that something like an angle grinder holder.I would have printed something but I cant find an STL . I am after a spool holder that screws to the wall. Its probably on the principle of an angle grinder holder where a curved holder allows a spool to be placed flat on the wall. In my case it cant be totally flush as the Python spool holders have a bearing on both ends. The real awkward part is the spool holder has a large gear attached so you cant use a strip rack where the rolls all side side ways.View attachment 512953View attachment 512954

Difficult to describe but I want something that allows the spool to sit like the first photo.

Imagine the second photo my arm is under the spool and screwed to the wall/cupboard. Allowing the the large gear to sit over the front of the spool holder.

Does anyone know of such a spool holder...

Sorry I am lost. I now know why I struggled at exams. I just don't follow what's being written.Sounds like you need a large dove tail like a 20mm wide slice of this lathe slide but the dove tail is angled V like so it holds the spool lip just below the centre line on a tangent? Would certainly be quicker to print that something like an angle grinder holder.

I forgot to attach a picture dohSorry I am lost. I now know why I struggled at exams. I just don't follow what's being written.

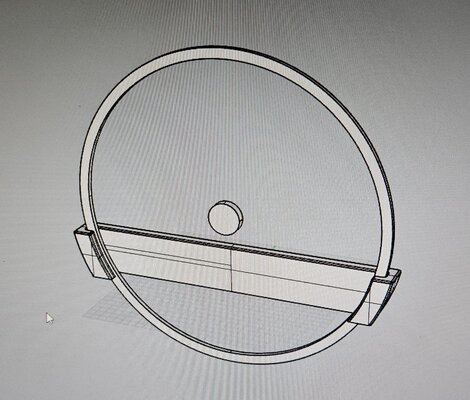

I am thinking of trying to adapt this if I get time over the weekend as my wife is ill currently. (Still not out of bed) and I can't spend time at the computer currently.View attachment 513013

I think a rough and ready solution might be to resize this and widen the front U towards the back.

Excuse the bad pictures but that's what I mean, just quickly sketched it up. Need to add 2 holes in the bar section for countersunk screws but otherwise it would just print in the orientation it'll mount on the wall, the back plate and all around the spool slot is 6mm thick and spool gap is also 6mm since for example prusa filament uses 5mm thick spools.Sorry I am lost. I now know why I struggled at exams. I just don't follow what's being written.

I am thinking of trying to adapt this if I get time over the weekend as my wife is ill currently. (Still not out of bed) and I can't spend time at the computer currently.View attachment 513013

I think a rough and ready solution might be to resize this and widen the front U towards the back.

Now I understand. Neat idea to be honest. I will have a play at the weekend. Thanks.Excuse the bad pictures but that's what I mean, just quickly sketched it up. Need to add 2 holes in the bar section for countersunk screws but otherwise it would just print in the orientation it'll mount on the wall, the back plate and all around the spool slot is 6mm thick and spool gap is also 6mm since for example prusa filament uses 5mm thick spools.

View attachment 513018

View attachment 513019

I can upload the step file so you can edit it further if you want.Now I understand. Neat idea to be honest. I will have a play at the weekend. Thanks.

Yes please that would be helpful. CheersI can upload the step file so you can edit it further if you want.

Did you get time to upload it ? And do you have a link please?I can upload the step file so you can edit it further if you want.

Sorry forgot got distracted printing hose fittingsDid you get time to upload it ? And do you have a link please?