galooph

Forum Supporter

- Messages

- 888

- Location

- Alsager, UK

For work, I have a multiple monitor setup, and recently splashed out on some new monitor stands. Each stand takes two monitors, one above the other, and is made out of 40mm box, with a 6mm thick steel base. So far, so good.

The brackets supplied to mount the monitors to the uprights, while sturdy, were an absolute pain to mount single handed. Trying to angle adjacent monitors to match was all but impossible. The best I could do was to let the brackets wedge against some nuts to get a consistent angle. Not ideal!

I'd got a bit of 100 x 50 x 4mm RHS kicking around, which I thought could work with a 1mm thick washer on each side of the 40mm box.

Being lazy, I came up with a bracket design that I could cut out with my bandsaw. Here they are in primer.

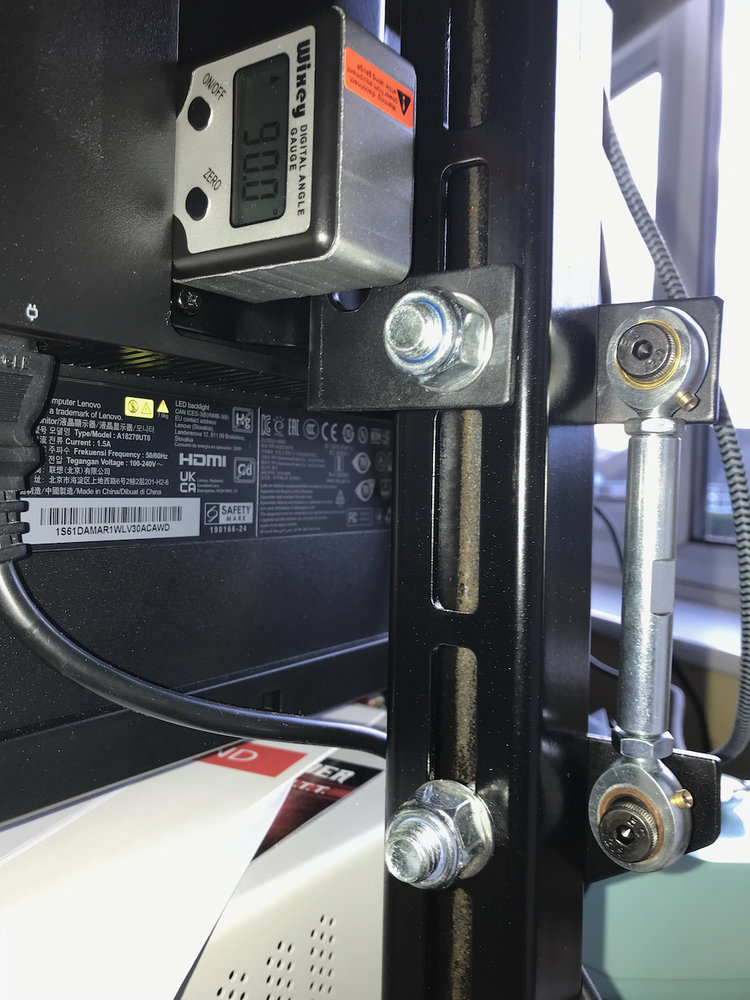

To make them easily adjustable, I went with a turnbuckle. I mean, how often can you incorporate rose joints into a monitor stand?

They actually work really well! Couldn't resist getting my Wixey gauge out Got the lower monitors set to 90°

Got the lower monitors set to 90°

and the upper monitors set to 75°

Still need to tidy up the cables, but that's for another day.

The brackets supplied to mount the monitors to the uprights, while sturdy, were an absolute pain to mount single handed. Trying to angle adjacent monitors to match was all but impossible. The best I could do was to let the brackets wedge against some nuts to get a consistent angle. Not ideal!

I'd got a bit of 100 x 50 x 4mm RHS kicking around, which I thought could work with a 1mm thick washer on each side of the 40mm box.

Being lazy, I came up with a bracket design that I could cut out with my bandsaw. Here they are in primer.

To make them easily adjustable, I went with a turnbuckle. I mean, how often can you incorporate rose joints into a monitor stand?

They actually work really well! Couldn't resist getting my Wixey gauge out

Got the lower monitors set to 90°

Got the lower monitors set to 90°and the upper monitors set to 75°

Still need to tidy up the cables, but that's for another day.