You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

Memmeddu

Member

- Messages

- 5,808

- Location

- Italia Sardegna

Piston rings suspected that while having a look at the ports on cylinder 3 and 4 lots of oil on them .The question is Memm, why is there no compression? Could be something quite simple, have a look before you scrap it.

Plus worn out pistons skirts knew that because of the characteristic scooping sound at minimum

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

Have you tried using a new blade ??? I dscovered after using a magnifying glass to examine things that one side of my blade was much more worn than the opposite side teeth edgesNo drawbar on the tailstock so the side load pushed it out. I swapped to the toolpost mt2 holder with a bolt then forgot to lock the cross slide

Nothing adjustable on ferrex. Its an awkward shape with the blade at an angle which doesnt seem to match up with the flat top, theres no sighting lines to aim it with.

Part problem is it cuts with the blade coming towards you so the work is against the saw and hidden, you can only look over the other side, not practical.

It would be much better if I could get some reverse cutting blades and reverse the motor so the cut is against the other side, then could see what Im doing!

This would also improve the frame, as it would be cutting against the solid jaw instead of the moving one.

Kram

Member

- Messages

- 8,460

- Location

- Sussex

It was 100% user error and bad aim from not being able to see my lines.

Started filing the clamps, more needed, it was getting dark ..

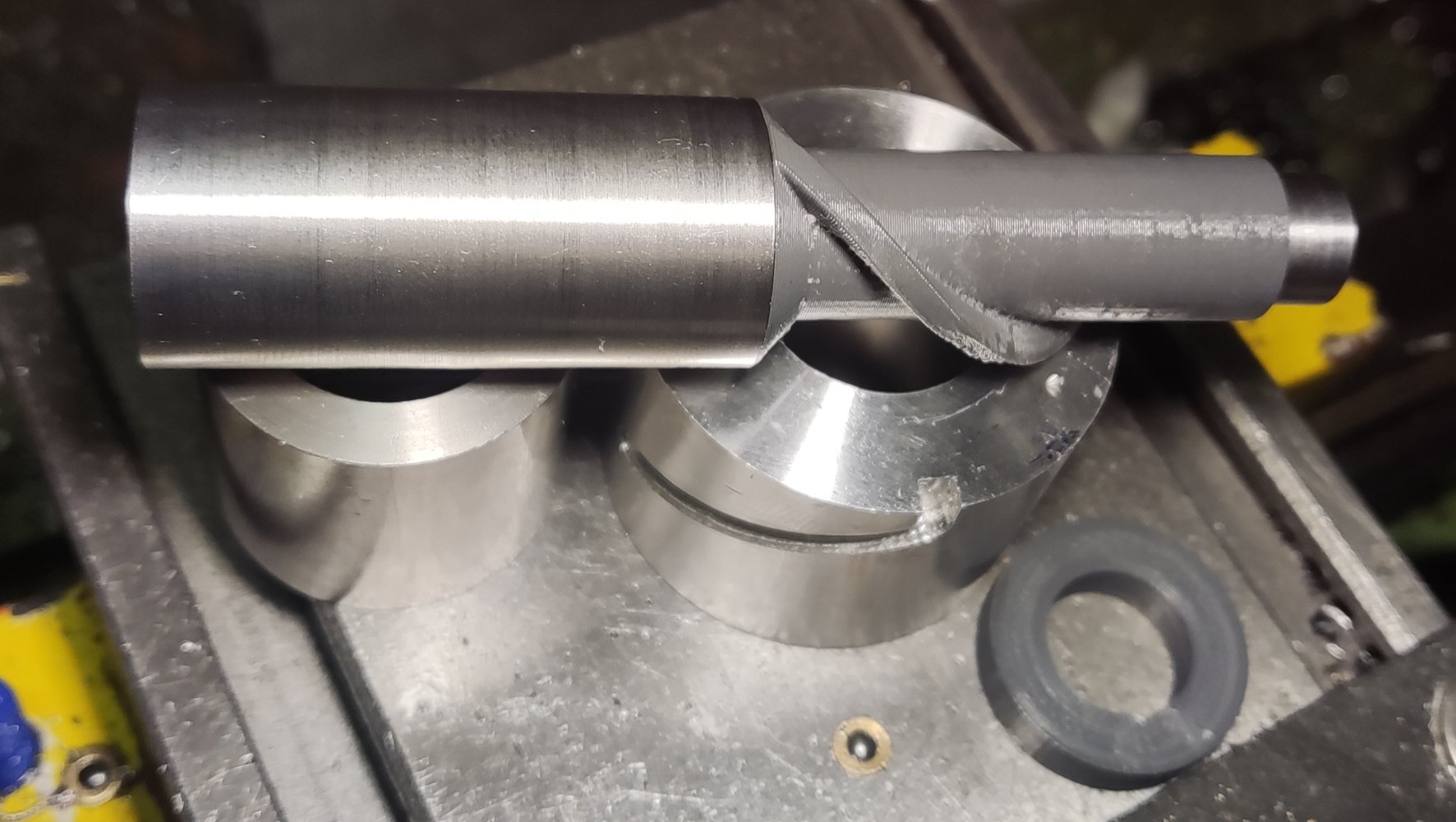

@Onoff I turned half of milling jig spindle. I was thinking to tap the missing end m12 and threadlock the other side in there. This will make it easier for shrink fitting the work peices, instead of gluing.

Turned it 23.03mm, slightly oversize for the shrink fit.

Started filing the clamps, more needed, it was getting dark ..

@Onoff I turned half of milling jig spindle. I was thinking to tap the missing end m12 and threadlock the other side in there. This will make it easier for shrink fitting the work peices, instead of gluing.

Turned it 23.03mm, slightly oversize for the shrink fit.

dobbslc

Member

- Messages

- 13,670

- Location

- Hertfordshire UK

Nice car! Is that at Snetterton?

MattF

Forum Supporter

- Messages

- 18,542

- Location

- South Yorkshire

This'll do for 6 months until we reroof the building..

A 10 year quick fix then.

E T

Member

- Messages

- 661

- Location

- Netherlands

He will need a bigger bucket.A 10 year quick fix then.

Munkul

Jack of some trades, Master of none

- Messages

- 7,748

- Location

- Cumbria

I've got some actual hose ordered. It'll slip down the side sheets and out of the wall. I also have a 2nd area to do exactly the same fix to.I'd poke a 10mm hole through the wall for the hose. You can always patch it up after..

We all say we're pitching in to reroof this summer. There's 6 of us who use the building. Arguably its even worse on the other side where the car workshop is...

magnet

Member

- Messages

- 1,456

- Location

- Stakeford England

I did the exact same thing in my shed after storm arwen blew the felt off. Had to buy a bit of time to save up for the matertials to reroof it. I used visqueen and slaters laths to make my chutes and directed the water out an open window. Needs must when the devil drives! Nice work mate.If one cannot repair the roof, one can make a drip tray to catch all of the leaks from a split sheet.

This'll do for 6 months until we reroof the building..

View attachment 433608 View attachment 433609

Memmeddu

Member

- Messages

- 5,808

- Location

- Italia Sardegna

Last hope someone discovered similar symptoms caused by a faulty fuel pump on the same model.Finished to repair my car today.

No displayed errors

Car has not compression anymore so it's dead.

Pretty sad about that , little bit disappointed because it could die before I've put almost 1000 worth of new parts in it .

Going to the scrapyard , it's an hard choice but she's not worth repair further more.

New engine is an option which I would not consider .

Too much work

Too much money

I need a new car

My neighbour has the same exact car and seeing all the sacrifices and work done, decided to buy one for me on tomorrow.

He has the same car and said "if doesn't work on yours , we'll replace it on mines"

Now if it works I'm most likely to keep it as long as possible but I'm planning to buy my brother's A4 B6 I've been using the last couple of months .

680 euros property documents and tomorrow I'll know how much for the insurance which would be surely much more money since it has 130HP .

The Audi needs little body fixes and a complete suspension rebuild.

If mine comes back to life I'll be happy and have little more time to gain the money to do documents etc.

Wish me good luck , anyways no regrets, I'm happy to have succeed the repair of mine even if it lasted just a morning before die .

It has an emotional value for me and I would had the regret of didn't try to save it.

Kram

Member

- Messages

- 8,460

- Location

- Sussex

Turns out that all of my M12 dies are turd and I need to get a proper HSS one. I couldnt revive them by a quick sharpen with a mounted stone may have another go tomorrow.

I resorted to my chinese M12x1. (I know my die holder screws are pssed)

Turned a 14mm shoulder to keep runout low but its still more than I'd like. I may redo it in one peice.

I resorted to my chinese M12x1. (I know my die holder screws are pssed)

Turned a 14mm shoulder to keep runout low but its still more than I'd like. I may redo it in one peice.

iNf

Forum Supporter

- Messages

- 724

- Location

- Hereford, England

Can't you single point it, I thought you bought some inserts recently?Turns out that all of my M12 dies are turd and I need to get a proper HSS one. I couldnt revive them by a quick sharpen with a mounted stone may have another go tomorrow.

I resorted to my chinese M12x1. (I know my die holder screws are pssed)

View attachment 433770

Turned a 14mm shoulder to keep runout low but its still more than I'd like. I may redo it in one peice.

View attachment 433771

Kram

Member

- Messages

- 8,460

- Location

- Sussex

Yes could but having not used lathe much for a year I have forgotten stuff. I will have to get some practise soon.Can't you single point it, I thought you bought some inserts recently?

iNf

Forum Supporter

- Messages

- 724

- Location

- Hereford, England

Yes could but having not used lathe much for a year I have forgotten stuff. I will have to get some practise soon.

addjunkie

Member

- Messages

- 14,482

- Location

- Northumberland. Reet oot in the sticks

Hes a teenager….youll get him back as a normal person in about 5 years!My son (14) is actually on a school trip in a very crazy country .

Fingers crossed to get him back as a normal person .

View attachment 433867