I made a circular former from a piece of 115mm round,place it in the “Norfolk “ bender and just pull the 12mm bar around it,there’s not much spring back,so ends up 90mm internal.nice smooth radius that!

whats your method?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

- Messages

- 14,816

- Location

- UK

@Hitch Can't you lower the dog over on a rope to go get it?Youngest keeps hitting his tennis balls over the fence into next doors garden.... issue is its a vacant house, so hard to retrieve....

Used to bits of wood like massive chopsticks last time... Another one over tonight.... so a 500mm pepsi bottle cut in half, screwed to a garden stick, we now have a 10ft long tennis ball retriever

View attachment 403915 View attachment 403916

3000alloy

Member

- Messages

- 159

- Location

- Ireland

Bastardised a Hardi backpack sprayer, quad sprayer, 6v battery and a sack trolley to mobilise for weed spraying.

Why? Well both shoulder straps are unusable and replacements for this model cannot be got. Works a treat. All can be dismantled to allow for the use of the sack trolley for other use. View attachment 220213

Oh how things change...so I upgraded, if you could call it that, to a more comfortable way to use this setup. Hard wired the setup above into my ride on. So now it gets 12v as opposed to 6v. Switch fitted the dash of my ride on to switch the 12v pump on and off. Really happy with this. Just need to refine the stowing of the lance perhaps.

Beeezer

Things are really chaining for the better….

- Messages

- 937

- Location

- Northampton

What tools are you using?? Nice job.View attachment 404076

View attachment 404075

Been enjoying the long sunny days with a bit o whittling. Two ball in the cage joined by a chain all out of one bit of wood. Really enjoying getting back to this.

- Messages

- 13,490

- Location

- England

I'll try that next time, one round his neck maybe.@Hitch Can't you lower the dog over on a rope to go get it?

Sergei Slovenija

Member

- Messages

- 1,256

- Location

- Slovenija Ljubljana

finyuk2005

Member

- Messages

- 859

second cut?!!The wife had the ðrone out again.

we havent even started our first!

Fraserb

Member

- Messages

- 1,525

- Location

- Scottish Borders

second cut?!!

we havent even started our first!

Yeah this was the 150 acre we got done early at 1st cut, its gone to head o needed cut and hopefully the rain comes tonight and it'll come away ok this time.

Morrisman

Forum Supporter

- Messages

- 9,066

- Location

- Staffordshire, England

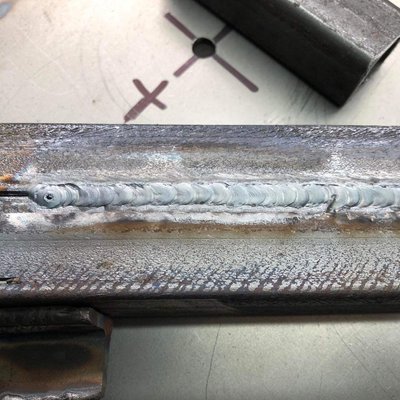

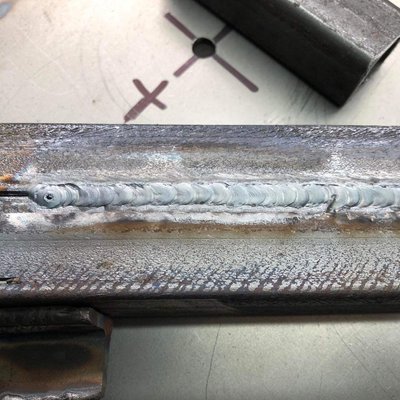

Today I've made the effort to start practising with my tig welder. And realised I've been using a 2.5mm tungsten instead of the recommended 1.5mm. Swapped the smaller one in, and had a play. Made a few fairly solid runs on various thicknesses and it all seems to work better now.

3mm angle iron.

2mm plate to 3mm box.

All I need now is more practise. Lots of it.

3mm angle iron.

2mm plate to 3mm box.

All I need now is more practise. Lots of it.

- Messages

- 13,490

- Location

- England

Dont get hung up on diameter, I'd be running a 2.4 on that all day long.Today I've made the effort to start practising with my tig welder. And realised I've been using a 2.5mm tungsten instead of the recommended 1.5mm. Swapped the smaller one in, and had a play. Made a few fairly solid runs on various thicknesses and it all seems to work better now.

3mm angle iron.

View attachment 404374

2mm plate to 3mm box.

View attachment 404375

All I need now is more practise. Lots of it.

Sergei Slovenija

Member

- Messages

- 1,256

- Location

- Slovenija Ljubljana

Welding ordinary steel is deceptive, it's the easiest TIG that can be. When switching to stainless steel, there will be a big difference in weld penetration, weld pool control and filler rod insertion. And yes, I put all my 1.6 electrodes away. I do not see the need for them when welding 1-4 mm, diameter 2.4 does an excellent job.Today I've made the effort to start practising with my tig welder. And realised I've been using a 2.5mm tungsten instead of the recommended 1.5mm. Swapped the smaller one in, and had a play. Made a few fairly solid runs on various thicknesses and it all seems to work better now.

3mm angle iron.

View attachment 404374

2mm plate to 3mm box.

View attachment 404375

All I need now is more practise. Lots of it.

Arc Tourist

Member

- Messages

- 5,054

- Location

- Wales

Is that an optical illusion, or do I detect a bent spindle ?

Morrisman

Forum Supporter

- Messages

- 9,066

- Location

- Staffordshire, England

I was also using the 2.4mm on the 1mm steel dummy fuel tank I made last time I cracked up the tig. It went well when the fit was perfect but pretty rubbish if there was any gap.Dont get hung up on diameter, I'd be running a 2.4 on that all day long.

They do say to start off practising welding on fairly thick plate.....

And I shall get some better glasses too, so I can see all the better.

selectedgrub

Member

- Messages

- 3,550

- Location

- New Zealand

Sow secret seeds. Big expectations. Harvest can only be checked in autumn 2024 or spring 2025.

Seed germination in nature is 2%, wait a couple of weeks.

It's intrigue, oh yes. May the "wood & brick" be with us.

You growing pot or a beanstalk?

selectedgrub

Member

- Messages

- 3,550

- Location

- New Zealand

Now made up from 4 pieces joined together