You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

Fraserb

Member

- Messages

- 1,525

- Location

- Scottish Borders

This rubble ramp is the beginning of my new yard surface,need MORE stone/rubble.ill then dress it down with scalpings.Its gonna cost!View attachment 344443

Stones gottwn a crazy price now, we did a shed in 2015 that needed 12000 ton of fill, would hate to price that now.

brewdexta

The biggest tool in the box

- Messages

- 5,754

- Location

- UK

The clear pipe and similar size blast gates are from Axminster, the smaller outlets came from a nearby factory refit.Neat job. Where did you source the clear pipe and blast doors?

Kram

Member

- Messages

- 8,467

- Location

- Sussex

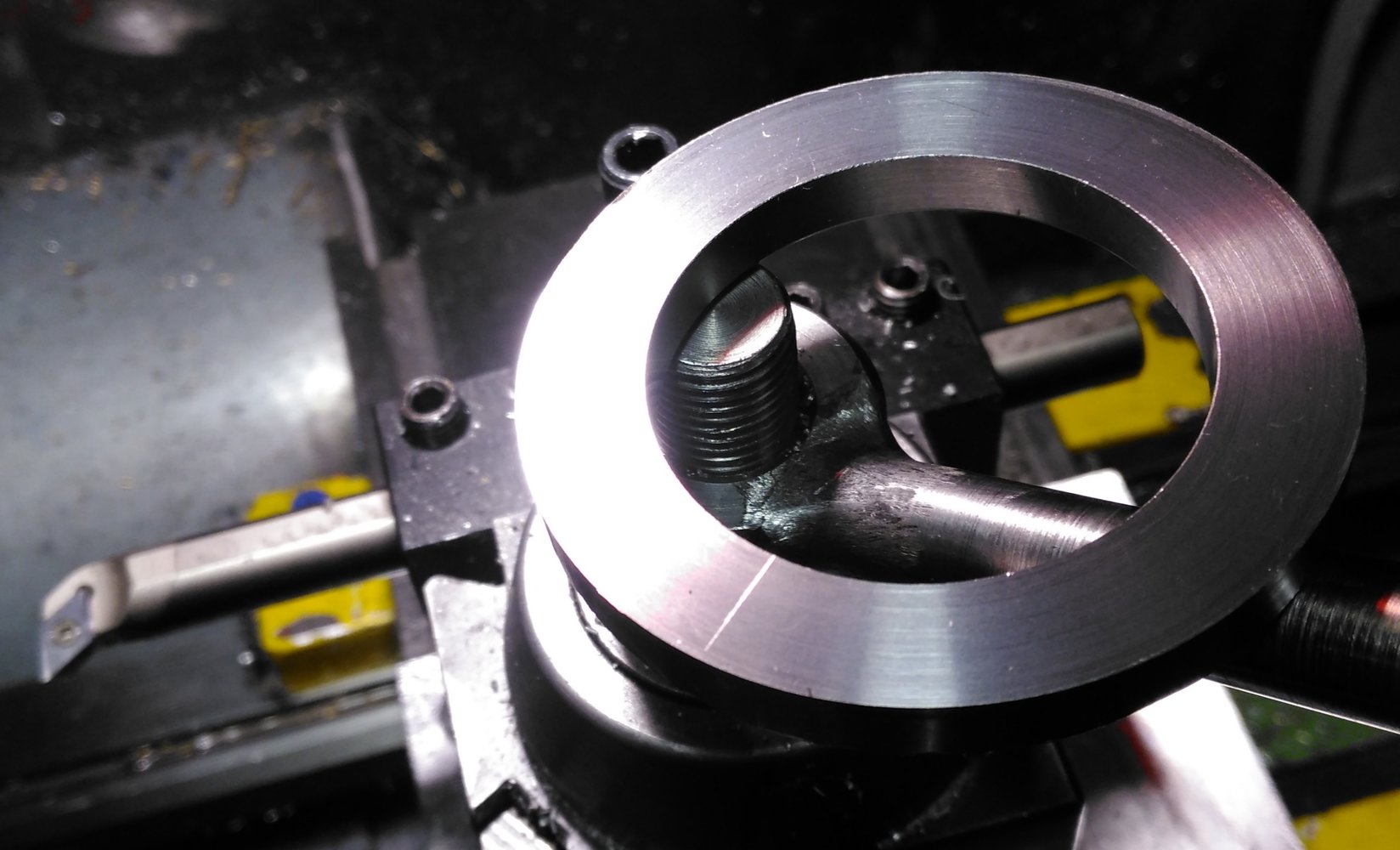

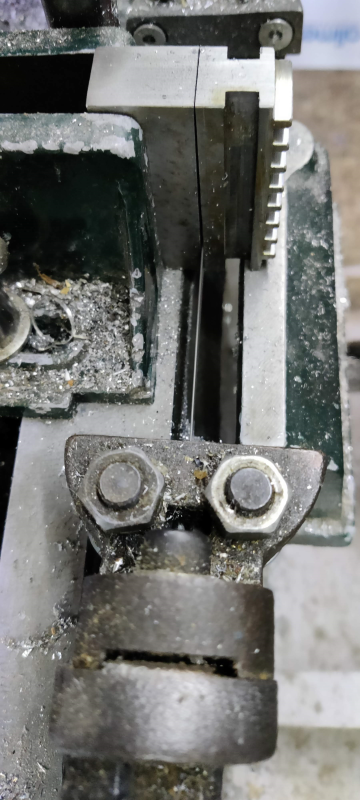

I started on @s410man 's washer. I didnt have a suitable offcut, so it was a slice off the 2.5" bar. Small grinder doesnt have the reach, hacksaw practise...

Bore and face done. This stuff turns nice. I didnt think the next bits through - I can grab the ID in my small 4 jaw, but theres no way to clock it in. I'll turn a 43mm mandrel and superglue it on instead.

Bore and face done. This stuff turns nice. I didnt think the next bits through - I can grab the ID in my small 4 jaw, but theres no way to clock it in. I'll turn a 43mm mandrel and superglue it on instead.

Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,495

- Location

- France, Brittany.

Can't remember the last time I used a hacksaw.I started on @s410man 's washer. I didnt have a suitable offcut, so it was a slice off the 2.5" bar. Small grinder doesnt have the reach, hacksaw practise...

View attachment 344495View attachment 344496

View attachment 344497

Bore and face done. This stuff turns nice. I didnt think the next bits through - I can grab the ID in my small 4 jaw, but theres no way to clock it in. I'll turn a 43mm mandrel and superglue it on instead.

Fair play.

8ob

Member

- Messages

- 14,293

- Location

- Nescient in the vale

This rubble ramp is the beginning of my new yard surface,need MORE stone/rubble.ill then dress it down with scalpings.Its gonna cost!View attachment 344443

Nick its worth rattling the cages of the local grab loader guys for hardcore, you should be able to get it for free.

Bob

James1979

Member

- Messages

- 8,290

- Location

- Orkney

Was that a kit or did you make the whole thing?So todays myself and @mtt.tr assembled my 1t hoist. Very pleased. Can lift 1t anywhere in my garage

View attachment 344477 View attachment 344478

Looks like the sort of thing I could do with. I like it because it low profile. I don’t have tons of headroom. About 10’

As an apprentice I must have cut off literally thousands of foundation bolts with a hacksaw, usually laying on my side in a puddle of hydraulic oilCan't remember the last time I used a hacksaw.

Fair play.

.

.I was also encouraged to practice using hacksaw and files left handed, which I still do to this day.

mtt.tr

Member

- Messages

- 8,138

- Location

- Essex/Suffolk border

Was that a kit or did you make the whole thing?

Looks like the sort of thing I could do with. I like it because it low profile. I don’t have tons of headroom. About 10’

It's bloody brilliant, I have a great level of envy

James1979

Member

- Messages

- 8,290

- Location

- Orkney

So was it built or bought?!It's bloody brilliant, I have a great level of envy

- Messages

- 3,017

- Location

- Never Never Land

I built it with another forum member. The garage was designed around the gantry. The two rails coming through the ceiling are bolted to four arches.Was that a kit or did you make the whole thing?

Looks like the sort of thing I could do with. I like it because it low profile. I don’t have tons of headroom. About 10’

Then out of two bits of angle either side we made up trollies which hole the four wheels to run the length of the garage. That also fixes the two UC’s which allowed me to keep the hoist up high.

The hoist is mounted onto a trolly made from channel section, that had four bearings in each corner running across the top of the two UC’s. This obviously allowed for max head room. Whilst not losing any capability around the room.

I have been doing a video for this for the last couple months. I’ll try and get it out next weekend maybe. Still a load to finish.

Dr.Al

Forum Supporter

- Messages

- 2,777

- Location

- Gloucestershire, UK

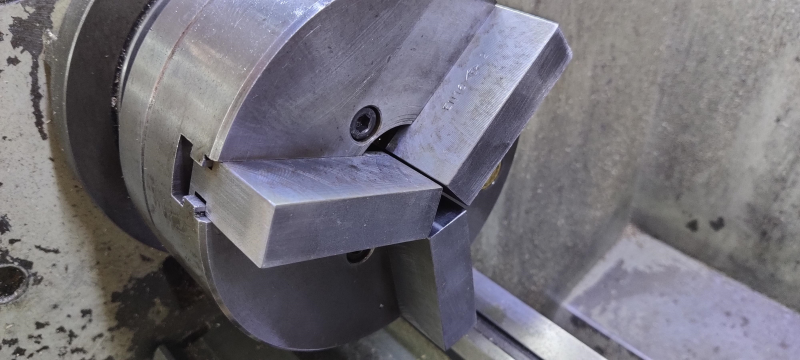

Last week (ish) I bought some soft jaws for my lathe:

They looked like this when fitted:

Today I cut them in half:

Then put them back in the lathe and skimmed them until they were about 0.2 mm proud of the chuck face

I then drilled four holes in each before reaming two of them and tapping two of them. I didn't take a photo of that bit. I've got a few bits of 20 mm-ish square-ish steel (including the offcuts from trimming the jaws) that I'm going to mill square and add holes to allow them to be attached to the new mini-jaws so that I've got bits that are sacrificial without damaging the teeth.

I wasn't in the mood for all the milling involved in making the jaws (not that it'll take long once I get started), so in the meantime I got on with some lathery.

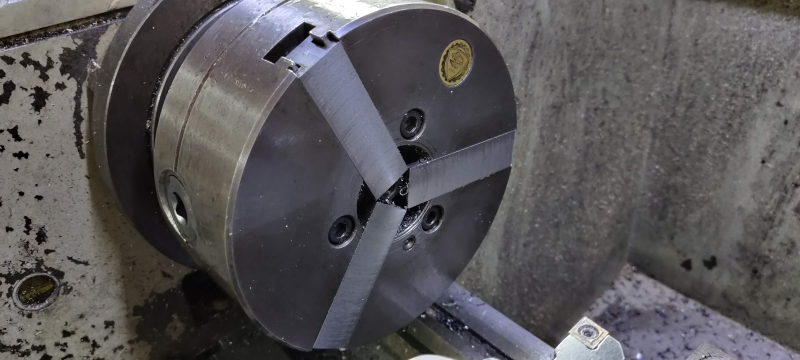

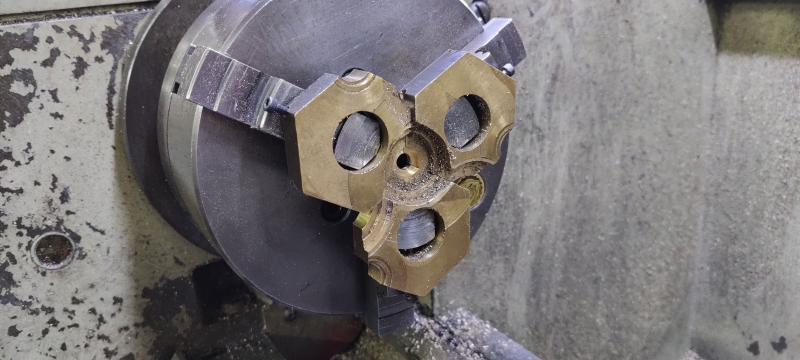

Before getting these soft jaws, I've used some simple hex jaws that I made out of some brass bar:

These have been used a lot and there's not much usable material left on them. Unfortunately, the design of these (with the screw holding the bar onto the jaws) means that there are only three usable "teeth" per hex piece. They also take a while to make as a result of boring the big hole in the middle and then drilling and tapping the mounting holes.

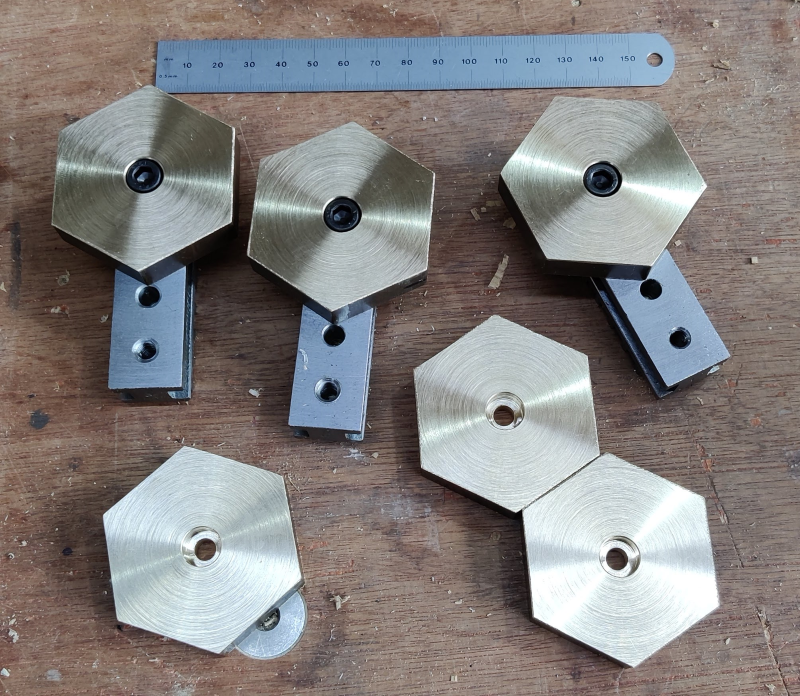

Today I made six new hex jaws out of the same brass bar.

These were much quicker to make as they only have a simple counterbored hole through the middle and nothing else. They also have six usable corners per set.

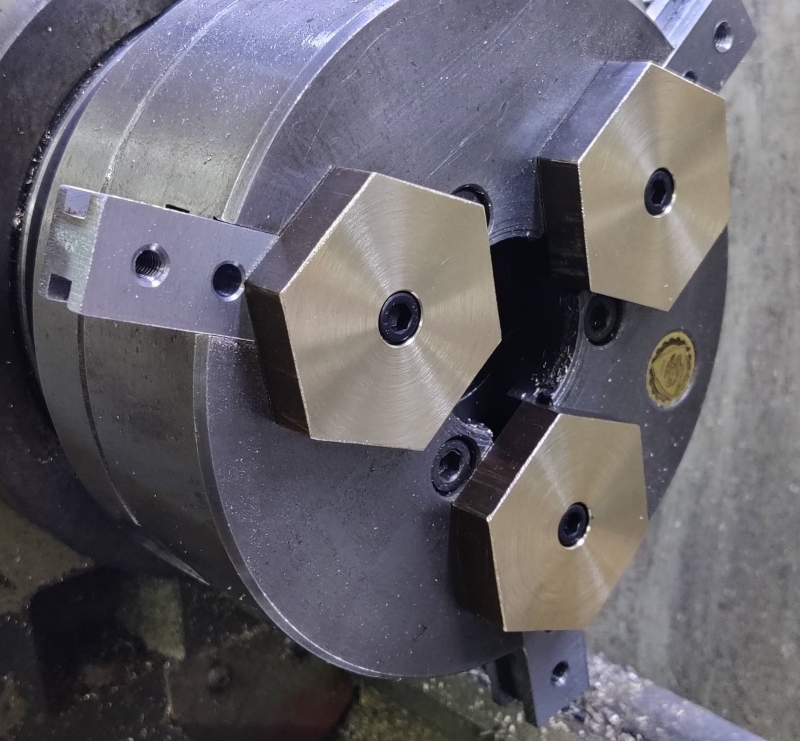

In place:

I might get on with the steel jaw "uppers" this afternoon. Or I might not, who knows?!

They looked like this when fitted:

Today I cut them in half:

Then put them back in the lathe and skimmed them until they were about 0.2 mm proud of the chuck face

I then drilled four holes in each before reaming two of them and tapping two of them. I didn't take a photo of that bit. I've got a few bits of 20 mm-ish square-ish steel (including the offcuts from trimming the jaws) that I'm going to mill square and add holes to allow them to be attached to the new mini-jaws so that I've got bits that are sacrificial without damaging the teeth.

I wasn't in the mood for all the milling involved in making the jaws (not that it'll take long once I get started), so in the meantime I got on with some lathery.

Before getting these soft jaws, I've used some simple hex jaws that I made out of some brass bar:

These have been used a lot and there's not much usable material left on them. Unfortunately, the design of these (with the screw holding the bar onto the jaws) means that there are only three usable "teeth" per hex piece. They also take a while to make as a result of boring the big hole in the middle and then drilling and tapping the mounting holes.

Today I made six new hex jaws out of the same brass bar.

These were much quicker to make as they only have a simple counterbored hole through the middle and nothing else. They also have six usable corners per set.

In place:

I might get on with the steel jaw "uppers" this afternoon. Or I might not, who knows?!

James1979

Member

- Messages

- 8,290

- Location

- Orkney

Cheers Kim. I’ll look forward to seeing thatI built it with another forum member. The garage was designed around the gantry. The two rails coming through the ceiling are bolted to four arches.

Then out of two bits of angle either side we made up trollies which hole the four wheels to run the length of the garage. That also fixes the two UC’s which allowed me to keep the hoist up high.

The hoist is mounted onto a trolly made from channel section, that had four bearings in each corner running across the top of the two UC’s. This obviously allowed for max head room. Whilst not losing any capability around the room.

I have been doing a video for this for the last couple months. I’ll try and get it out next weekend maybe. Still a load to finish.

Made another shelf in the gap above the wood storage rack:

It's made good use of an otherwise empty corner and provides an area to keep all the woodworking power tools and consumables in one place, subject to making some kind of flat storage divider for sandpaper.

And the empty shelf it's created will help in decluttering the benches.

It's made good use of an otherwise empty corner and provides an area to keep all the woodworking power tools and consumables in one place, subject to making some kind of flat storage divider for sandpaper.

And the empty shelf it's created will help in decluttering the benches.

Dcal

Forum Supporter

- Messages

- 4,075

- Location

- Antrim Northern Ireland

Variation on a theme

I did this one a couple of years ago.

Free hand plasma on 1mm stainless stuck to a white plastic backing.

I printed the numbers, cut them out to make a stencil, drew then on with a felt tip and did my best to keep to the lines.

It's rustic, but I quite like the effect (that's my story and I'm sticking to it) and seems to have lasted pretty well

I bet it doesn't.And the empty shelf it's created will help in decluttering the benches.

They'll just got full of other stuff instead.

sardine

Member

- Messages

- 3,729

- Location

- Buckinghamshire

I'm sure everyone on here already knows this but I've found people that don't know that hacksaw blades come in different TPI, a 14 ( with cutting paste ) will make a big difference in effort on a big cutting job like that, probably save you half the time.I started on @s410man 's washer. I didnt have a suitable offcut, so it was a slice off the 2.5" bar. Small grinder doesnt have the reach, hacksaw practise...

View attachment 344495View attachment 344496

View attachment 344497

Bore and face done. This stuff turns nice. I didnt think the next bits through - I can grab the ID in my small 4 jaw, but theres no way to clock it in. I'll turn a 43mm mandrel and superglue it on instead.

| 14 | Large profiles, aluminium, softer metals |

| 18 | General workshop projects |

| 24 | Steel plate up to 5/6mm thickness |

| 32 | Hollow sections and steel tubing |