If there's no fabrication drawings, I hope there's a lot of calculation drawings!Thats a lot of overhangWhats going underneath?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

Edward Teach

pre-moderated

- Messages

- 992

- Location

- South West England

I did notice this also,Thats a lot of overhangWhats going underneath?

But I would imagine it's all in hand

Designed and calculations,by an architect and structural engineer,probably fresh air underneathIf there's no fabrication drawings, I hope there's a lot of calculation drawings!

.

.DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

I wonder if the overhang it is to do with the square footage it stands on & the ratable value > IE the smaller the footprint it falls into a lower council tax & ratable tax band.Designed and calculations,by an architect and structural engineer,probably fresh air underneath.

James1979

Member

- Messages

- 8,290

- Location

- Orkney

Like those medieval houses that got bigger as they went upI wonder if the overhang it is to do with the square footage it stands on & the ratable value > IE the smaller the footprint it falls into a lower council tax & ratable tax band.

Farside

Badly Welded Man

- Messages

- 6,446

- Location

- Ireland

I can't see any.All made from plans only,no fabrication drawings,that’s what I blame my 3 errors on.

Mind you, I made a couple of glaring errors when building my workshop and managed to cover them quite successfully.

I corrected them,the frame wouldn’t have gone together properly otherwise.I can't see any.

Mind you, I made a couple of glaring errors when building my workshop and managed to cover them quite successfully.

A replacement material support block,for the outfeed side of the bandsaw.

Amazing how Axminster supply a good product (I assume they have some design input),yet leave off this vital part,without it your stock isn’t correctly supported.

Piece of 28mm square,and a 1/4” slot in the mill.

Amazing how Axminster supply a good product (I assume they have some design input),yet leave off this vital part,without it your stock isn’t correctly supported.

Piece of 28mm square,and a 1/4” slot in the mill.

dan.taylor.1

General Tinkererer

- Messages

- 2,750

- Location

- Kendal, Cumbria

My axminster bandsaw has as much table either side of the band, probably as it swivels to 45° one way and 60° the other?A replacement material support block,for the outfeed side of the bandsaw.

Amazing how Axminster supply a good product (I assume they have some design input),yet leave off this vital part,without it your stock isn’t correctly supported.

Piece of 28mm square,and a 1/4” slot in the mill.

View attachment 289535View attachment 289536

This is also a swivel head,which caused the previous one to wear thru.My axminster bandsaw has as much table either side of the band, probably as it swivels to 45° one way and 60° the other?

I recently bend som aluminium tube, over an old powersteering pulley and these came out perfect, unlike the picture I took.View attachment 2892228mm copper lengths for compressed air cooler. Wanted a 180 degree bend in them. Have a cheap tube bender tool which works fine when Ive tried on brass tube. On copper it seems to twist/kink/flatten the tube instead

I hammered the bends back into a semi round shape. Might chop them off and buy some elbows.

Kram

Member

- Messages

- 8,459

- Location

- Sussex

Cut the adaptor plate down, so its near enough done. The arms are a tight fit so I might flap disk the plate down a bit.

I wanted to do more stuff, some spacers I need to make up, but I went out for a trail run instead. 24km, longest run in ages, legs a bit sore now.

gaz1

Member

- Messages

- 20,510

- Location

- westyorkshire

well you know i have a chest issue but this has been done in 2 days

roof off from this stone slates then off the scafolding so its a triple lift even with 3 men on it

job ended

1/2 of 30 ft dormer done today from the previous pics above

felted and latted so waterprrof within reason for tonight

part 2 is this side to the end of the wall where roof ends

so we are clear the floor area is 6 8x4 sheets on the floor so one hell of a good space to use

oh and chainsaw cutting most of the wood off

roof off from this stone slates then off the scafolding so its a triple lift even with 3 men on it

job ended

1/2 of 30 ft dormer done today from the previous pics above

felted and latted so waterprrof within reason for tonight

part 2 is this side to the end of the wall where roof ends

so we are clear the floor area is 6 8x4 sheets on the floor so one hell of a good space to use

oh and chainsaw cutting most of the wood off

Arc Tourist

Member

- Messages

- 5,054

- Location

- Wales

Got to do what you got to do to beat the weather destroying your previous efforts.

gaz1

Member

- Messages

- 20,510

- Location

- westyorkshire

the weather is an issue for start offIs that good going with a chest issue?

I can do joinery work dont think i cant the other person is the joiner not me

lugging stone slates off the roof with no lift isnt an easy job to do its very heavy work and 3 lifts keeping safety in mind weight on scaffolding is very important as it can bring the lot down as well as you

I have copd so lungs are coughing the more strain i put on them good in some ways bad in others

lugging around over a long distances gets to you when deliveries arrive late as in yesterday

so in that lot yeah its good going to say youve ripped the wooding out placed 17ft 9x3s wood beams above x3

leveled the front and window wooded the front to support the 6x4 front beam

wooded out the roof area in 6x2s

plyboarded the roof area felted and latted the roof and temporary water proofed the building for the owners

in a 11hr working day not including transport

wood alone for the job is 3,000

the other job is decking 10,000 worth just in wood materials

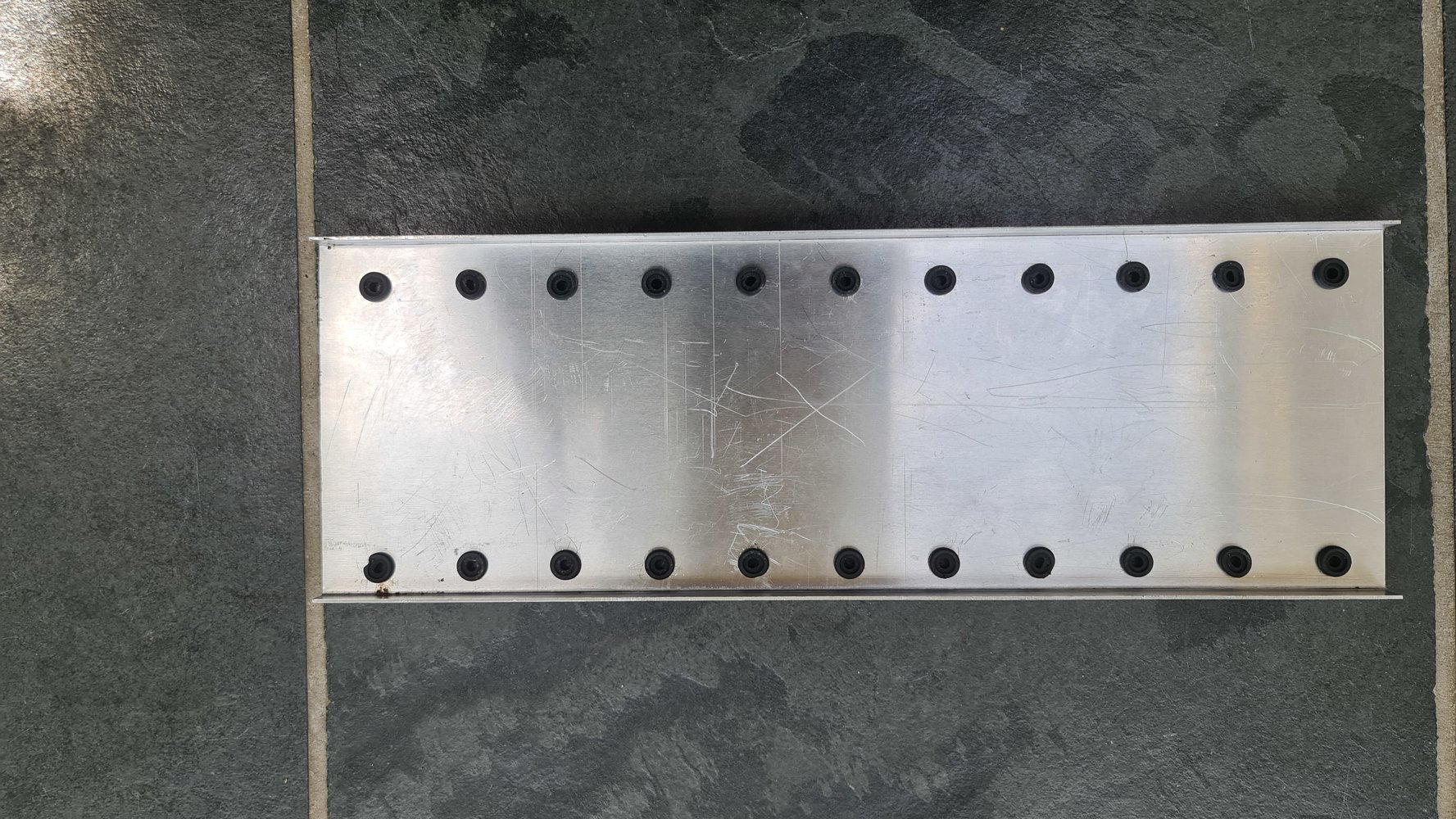

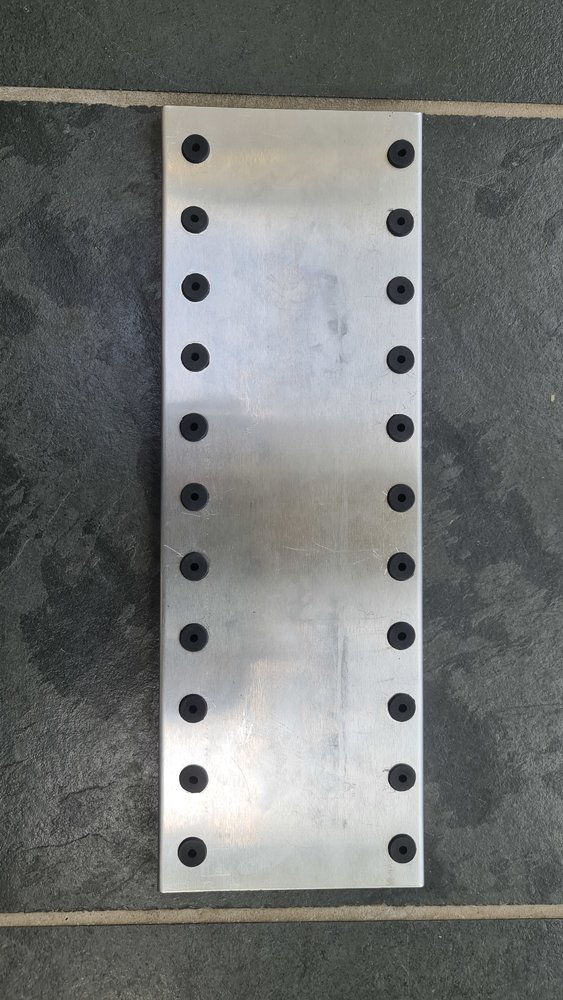

A hard drive tower for our home server.

My brother is a film buff and only downloads in 4k. Hence loads of 8tb drives. This will hold 11 of them. Cooling fans will be fitted.

Drilled all the holes on the Bridgeport with dro. Then used my nice little 1 ton manual folder.

Drives on rubber grommets to stop vibration.

My brother is a film buff and only downloads in 4k. Hence loads of 8tb drives. This will hold 11 of them. Cooling fans will be fitted.

Drilled all the holes on the Bridgeport with dro. Then used my nice little 1 ton manual folder.

Drives on rubber grommets to stop vibration.

They are all full and he wants instant access. Drives sleep until needed to save power and prolong life.you might be better having a drive bay with removable drive slots

something like me i like save files alot so extra hard drive slots that can be unplugged and another drive inserted even better

His biggest hero is Linus tech tips.

How many other home users have over 100tb of storage

My brother collects computers the way I collect machines