Edward Teach

pre-moderated

- Messages

- 992

- Location

- South West England

Lol,

I hadn't seen the Marshalling Signals at first

.

Lol,

What’s bad about the original ? The new one will draw warm air in, def not goodreplaced the badly designed air filter in my 306 with a pipercrossView attachment 299481

old one looking a bit weathered

View attachment 299482

heavy and mounted way too low and there's a chance it can suck up water if you go through too deep a puddle and the metal airbox isn't sealed tightWhat’s bad about the original ? The new one will draw warm air in, def not good

I used to have a tuned Toyota Corolla Gti with a 4age motor. A cold air box made 1 kw on the dyno with the same cone filter.heavy and mounted way too low and there's a chance it can suck up water if you go through too deep a puddle and the metal airbox isn't sealed tight

I don't think the warm air intake will be a noticeable issue on a car with 90bhp. I am planning on shifting it to behind the headlight eventually mind but the induction kit only came with piping to mount it where it currently is.

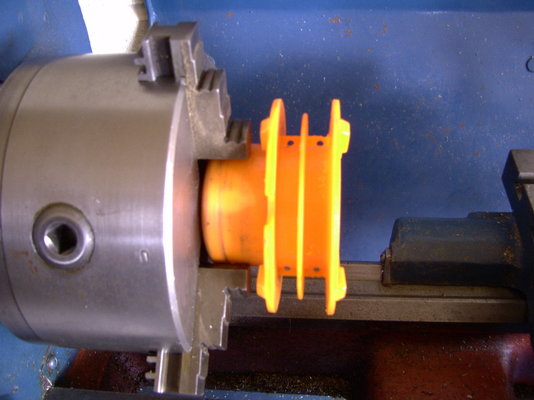

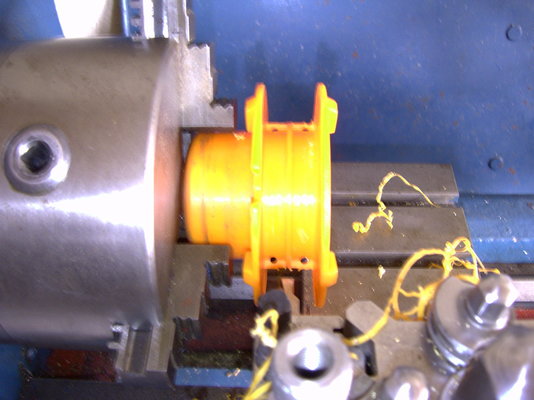

I may be wrong but on ours that's all that holds the wire in, cutting it out would mean it just chucks all the wire out at once.Put on my best ripped jeans to have a go with the new petrol strimmer today, but found that the line spool needed some modification to be more user friendly. The spool had a partition in the centre which limited the amount of line it would hold and made it a pain to wind. So, I put it in the lathe and shaved the partition down. Its the little things that make life easier.

View attachment 299574 View attachment 299575

On mine the two holders allow two cords to be round on at once,Put on my best ripped jeans to have a go with the new petrol strimmer today, but found that the line spool needed some modification to be more user friendly. The spool had a partition in the centre which limited the amount of line it would hold and made it a pain to wind. So, I put it in the lathe and shaved the partition down. Its the little things that make life easier.

View attachment 299574 View attachment 299575

Every one I've ever used has had a little gap where you pinch the wire and then wind one half each side.On mine the two holders allow two cords to be round on at once,

It works fine Dan, just like the strimmer I had overseas.I may be wrong but on ours that's all that holds the wire in, cutting it out would mean it just chucks all the wire out at once.

The line is wound in the same direction and the feed holes are on the same horizontal plane so the line still winds off without issue. The only difference is I peel off 20 feet of line, fold it in half and thread it through one hole until it reaches the middle and start winding. Seems simpler than trying to deal with two lines and the spool, where sometimes you need three hands. Anyway, its worked for me over the years, so I guess I'm also like a dinosaur in the age of mammals.On mine the two holders allow two cords to be round on at once,

Is that a Hayter Hobby? I’ve had exactly the same experience with mine. Several times now!The mower. The handle snapped off where it bolts onto the deck, again. Becoming a bit of a Trigger's broom, this one.

View attachment 299681 View attachment 299682

Found a piece of oval section tubing in the scrap pile, think it was once part of the kids' climbing frame.

A bit of re-shaping with a vice and a BFH to fit the handle tubing into one end.

A while ago somebody posted a link to a set of unbelievably cheap but good quality Chinese hole saws, I knew I'd find a use for them some day.

View attachment 299684 View attachment 299685

Welded up. Hopefully by not flattening the tube where it meets the deck bracket it'll be a bit less prone to fatigue.

View attachment 299686

A couple of coats of Halford's finest, think it'll do. Not bad for a 20 year old machine.

I cut the tube at 45deg with some vague idea that it'd spread the load and be less likely to crack around the weld line. Seems to have worked OK for the other side so far

View attachment 299687

It's a Sovereign, cheapy Italian-made one with a 3.5HP Briggs engine, all the DIY sheds were knocking them out with various different badges on at the time. Deck is slowly rotting to bits but the engine is sound, a new carb diaphragm every few years and it just keeps going.Is that a Hayter Hobby? I’ve had exactly the same experience with mine. Several times now!

I was on my way to buy a new mower when I popped in to see a Mate at his garage. He happened to have rescued a Hayter mower from a skip with a broken handle like yours. He had welded it up a£25 later it was mine.It's a Sovereign, cheapy Italian-made one with a 3.5HP Briggs engine, all the DIY sheds were knocking them out with various different badges on at the time. Deck is slowly rotting to bits but the engine is sound, a new carb diaphragm every few years and it just keeps going.