God mode restorations

Member

- Messages

- 8,098

- Location

- uk colchester

Hi..what discs and calipers are you using...awesome looking motor.

OK cool. Nice set up.. I hope to get to that point in the future..I have just stripped my front end down...got some inner wing mods to do.Thanks...

Discs are AP 295x25

Calipers are off a lotus exige..

Disc bells and mounts i designed myself and had machined

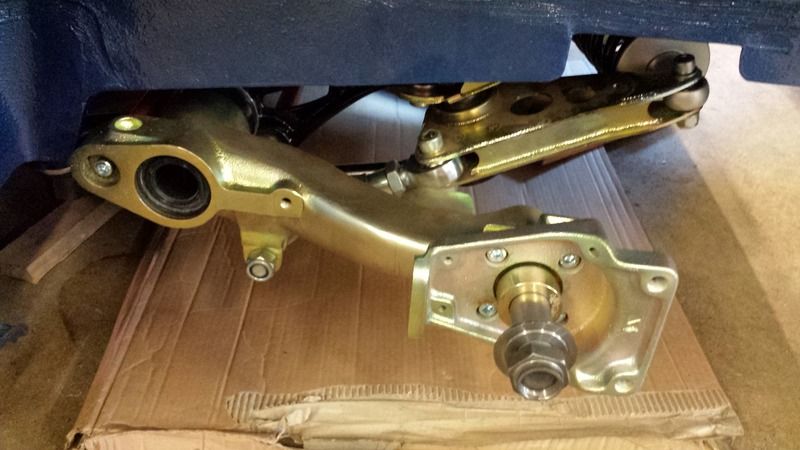

serious envy lol, how come you still have the torsion bars in i thought that kit done away with the need of them

I remember reading decades ago in CCC, due to needing to keep the original mounting points in use, someone had engineered a rocker in there, so shocks in the original position were operated closer to 1:1 to give more control - as the suspension moved, it compressed one end, while compressing the other at the same time via pushrod and the rocker. Ingenious!

Do you have a vapour blasting setup yourself?