You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rubber Cutting

- Thread starter Brad93

- Start date

'big ball bearing'? go on then, please telli am goign to be "that guy" and say will a bit of innertube, craft knife and big ball bearing trick not work?

Brad93

Member

- Messages

- 19,285

- Location

- Essex, United Kingdom

You've just given me an idea.Grind the teeth off a hole saw to make a knife edge, and press it out. A bit of WD40 helps lube it up

Brad93

Member

- Messages

- 19,285

- Location

- Essex, United Kingdom

I did think innertube but I need the rubber to be fairly flat.i am goign to be "that guy" and say will a bit of innertube, craft knife and big ball bearing trick not work?

Brad93

Member

- Messages

- 19,285

- Location

- Essex, United Kingdom

I've got some tape cutters, hardened steel round blocks. I'd just need to make a die like you say.Could you turn up a die if it’s only thin?

Piece of round stock with a short round hollow section that’s got an edge turned on it and use a piece of wood to cut on?

Edit - just seen holesaw idea.

Agroshield

Member

- Messages

- 6,280

I did think innertube but I need the rubber to be fairly flat.

Use the bit from the bottom then. That's where they are always flat.

A piece of pipe with a bevel turned, filed or angry ground on it, lubricated with water and driven in with a BFH over a plastic chopping board will normally cut rubber. For the ID hole, the chamfer should be on the inside of the pipe; for the OD hole, the chamfer on the outside. The ID is near 2 1/2" so that might be a standard pipe.

Another way for the OD is to sandwich between two pieces of plate and turn in the lathe with sharp HSS.

Mick Annick

Forum Supporter

- Messages

- 2,933

- Location

- Burgundy, France (450 miles SE of Somerset)

These will be able to help with the rubber, might make them for you too

www.coruba.co.uk

www.coruba.co.uk

Coruba | Rubber Suppliers and Manufacturers

One of the UK’s leading suppliers of high-quality rubber sheeting, rubber matting and rubber products. For enquiries, call 01702 560194.

For cutting the center out of comething like this, craft knife for the outside then you lay the rubber/gasket material over what ever you need place a big ball bearing over it and give it a decent wallop with a hammer/mallet and it will cut the inside circle out perfectly by nipping it between the 2.'big ball bearing'? go on then, please tell

I’ve made loads of seals for the mine like that with 3 inch crusher balls

Thinking back Brad I may still have some seal rubber in stores if your not sorted Ile look tomorrow.

Agroshield

Member

- Messages

- 6,280

How critical is it Brad?

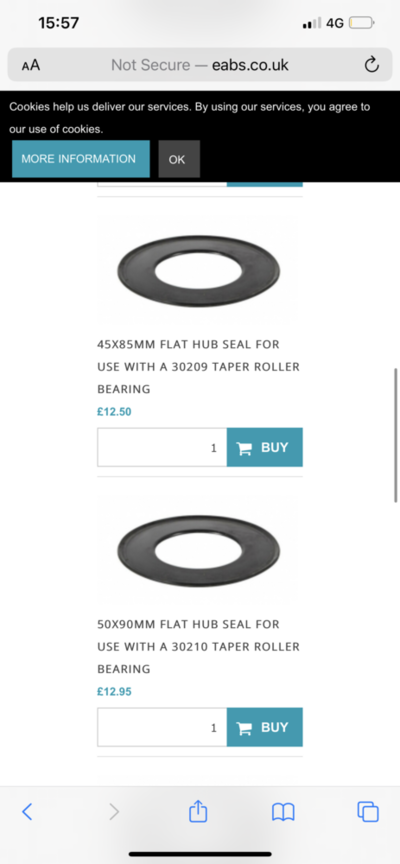

I did not spot it before: he wants 90 OD x 63.5 ID. The one in the image he shows (30210) that is the correct OD but only 50mm ID. So the problem would be solved if we could find a foolproof way of opening up the ID of the bought one (and it will be exactly the correct material).

Glue it to a piece of something. Centre it up in a 4-jaw. Hold a scalpel in the toolpost so it looks like a boring bar and slice out the centre.

In my fitting days, on a water treatment plant we used to make all our pipe flange joints (just round rings) using a joint cutter, which was basically a set of Trammell's with a point at one end, as normal, and a blade at the other, I think it was just a standard Stanley blade.

Brad93

Member

- Messages

- 19,285

- Location

- Essex, United Kingdom

Yep. We had one, James Walker. For cutting CNAF and graphite jointingIn my fitting days, on a water treatment plant we used to make all our pipe flange joints (just round rings) using a joint cutter, which was basically a set of Trammell's with a point at one end, as normal, and a blade at the other, I think it was just a standard Stanley blade.