- Messages

- 3,017

- Location

- Never Never Land

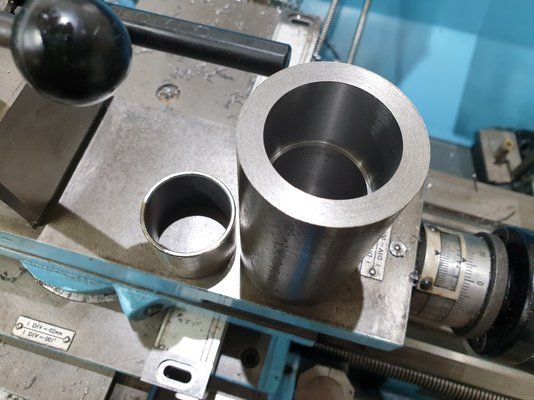

Try the box section in a vice and mag drill to that. See if it holds it well. If it’s chunky enough it should hold it.Had an idea that if I tacked some chunky box section to where I need to drill so I could stick the drill to it, like a spacer. But apparently you need about 10mm of steel for a good magnetic hold?

Might try later as I could do with the mag drill to core out the hole for the new tube once the new steels in

magnet needs to be on to start the drill but will start up on a concrete floor no bother. If it comes unstuck and the magnets still powered it ain't stopping

magnet needs to be on to start the drill but will start up on a concrete floor no bother. If it comes unstuck and the magnets still powered it ain't stopping

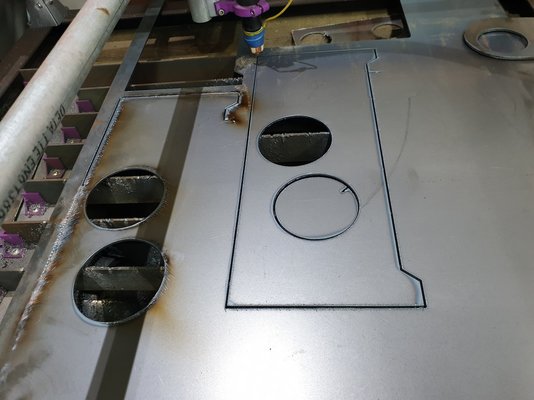

when I cut the bits of box section the plates sprang into a curve! Little bit of bending in the vice and was fine but a bit annoying, then by the time I had ground out some relief for the weld it was pretty much just a bit of plate.

when I cut the bits of box section the plates sprang into a curve! Little bit of bending in the vice and was fine but a bit annoying, then by the time I had ground out some relief for the weld it was pretty much just a bit of plate.

fftopic: But more importantly! had the news i have been waiting years to hear, planning for my dream workshop was approved! although don't call it a workshop, council don't like the word workshop, its just a big garage

fftopic: But more importantly! had the news i have been waiting years to hear, planning for my dream workshop was approved! although don't call it a workshop, council don't like the word workshop, its just a big garage

missing from both sides anyway.

missing from both sides anyway.

was a very rusty looking stone in my defense and i did look like a sheared bolt before i welded it

was a very rusty looking stone in my defense and i did look like a sheared bolt before i welded it