eLuSiVeMiTe

Member

- Messages

- 16,282

- Location

- ......

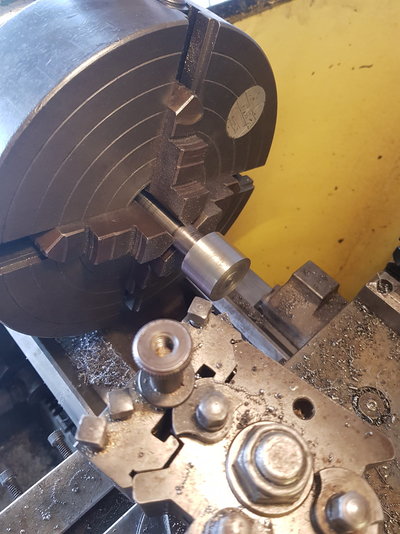

No pictures of the paint.Paint is all done now, will start reassembling tomorrow. In the meantime I thought I'd to a test run for the spindle threading.

View attachment 185786

For some reason I ground my 60 degree threading tool the wrong way so it can't get tight up to a face.Time to drag out my big grinder and grind a new tool.

View attachment 185785

You can see how much use it gets.Its perfect for grinding lathe tools but it's very slow going to I usually use my much faster bench grinder. I may refurb this too eventually.

How'd the second coat come out.

Is there a trick to machining weld? I've never had any luck with it, it always seems to behave like it's rock hard and deflect the tool. Strange because it files just fine so it can't be that hard.

Is there a trick to machining weld? I've never had any luck with it, it always seems to behave like it's rock hard and deflect the tool. Strange because it files just fine so it can't be that hard.

) but the picture makes it look worse than it is. That cover plate needed boring to fit the bigger nose diameter too.

) but the picture makes it look worse than it is. That cover plate needed boring to fit the bigger nose diameter too.

The drill is now where I store my planer shavings.

The drill is now where I store my planer shavings.

I'll order a proper one when I figure out what belt the little Herbet drill next to it needs. I also need some small machine screws for the cover plates and some switchgear, right now I plug it into my inverter and use the controller on my lathe to turn it on, not the most ideal (or safe

I'll order a proper one when I figure out what belt the little Herbet drill next to it needs. I also need some small machine screws for the cover plates and some switchgear, right now I plug it into my inverter and use the controller on my lathe to turn it on, not the most ideal (or safe