Dieselman 63

Forklift Certified

- Messages

- 5,875

- Location

- Wellington, New Zealand

That's good to know, I usually use baking paper but masking tape would be easier to apply. I'm not a fan of the fibreglass either, much prefer the belt cover on my Herbert drill; about 3/8" thick cast iron.

What’s the guard on the chippie made of, iron or ally?

) and the new paint has been delivered.

) and the new paint has been delivered.

I think I'm just going to ask for a refund, even if I replace the screw the whole thing is in a bit of a bad way, there's a lot of surface rust in it, all the critical ground surfaces seem okay though. There's a lot of stiff dried grease in there too.

I think I'm just going to ask for a refund, even if I replace the screw the whole thing is in a bit of a bad way, there's a lot of surface rust in it, all the critical ground surfaces seem okay though. There's a lot of stiff dried grease in there too.

I suspect the original loose one was lost and someone just dropped a spare (But heavily used) one in to sell it looking complete. The person I bought it from says he got it in a job lot of engineering tools and doesn't really know a lot about them, I don't think he's tried to rip me off but whoever he got it from possibly was.

I suspect the original loose one was lost and someone just dropped a spare (But heavily used) one in to sell it looking complete. The person I bought it from says he got it in a job lot of engineering tools and doesn't really know a lot about them, I don't think he's tried to rip me off but whoever he got it from possibly was.

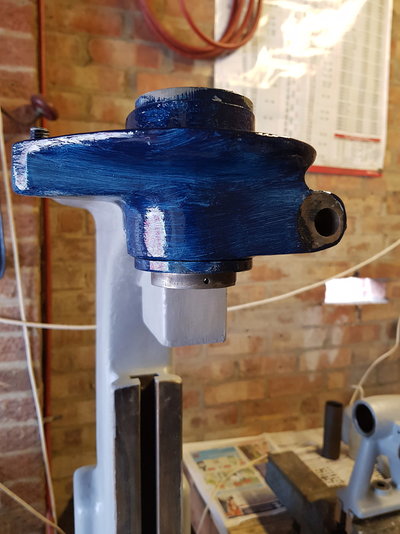

and with that, it was just about ready for paint:

and with that, it was just about ready for paint:

Time to drag out my big grinder and grind a new tool.

Time to drag out my big grinder and grind a new tool.