- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New to me - Colchester Triumph

- Thread starter Lewis_RX8

- Start date

Lewis_RX8

Member

- Messages

- 1,556

- Location

- Scotland

I know how to use carbide , hhs is a forgotten skill , Joe pieczynski on YouTube, who is a fantastic machinist is a great believer of HSS . Of course he uses carbide also . Me being a hobbyist, I do it for my chill time and love using HSS tools .

I have seen a few of his videos really helpful guy ,Think I will keep my HSS handy for odd custom ground bits and use carbide for general stuff and finishing. Not that any ones paying me do to it like hood but would rather spend more time turning than grinding aswell lol

slim_boy_fat

Member

- Messages

- 29,188

- Location

- Scottish Highlands

but I am retired and only play in the garage without time restraints

I think there are quite a few of us on here like you.

It did have a place….on a treadle powered lathe in the 1800’s

That's almost my era.....

Lewis_RX8

Member

- Messages

- 1,556

- Location

- Scotland

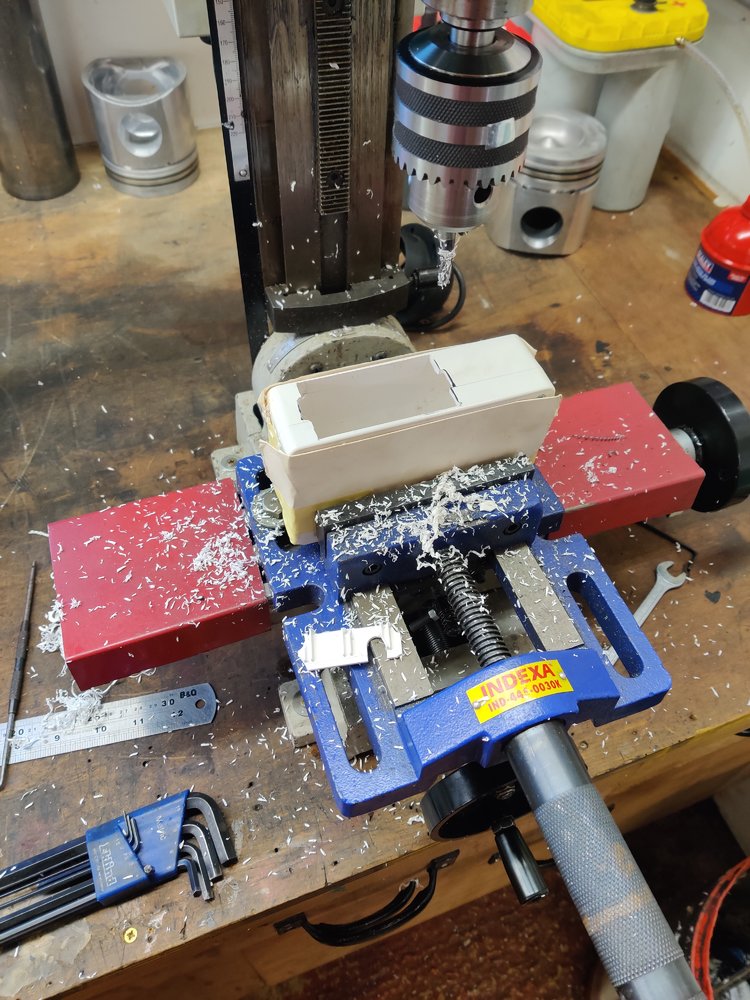

Making a mess milling out the box for my RPM display and potentiometer

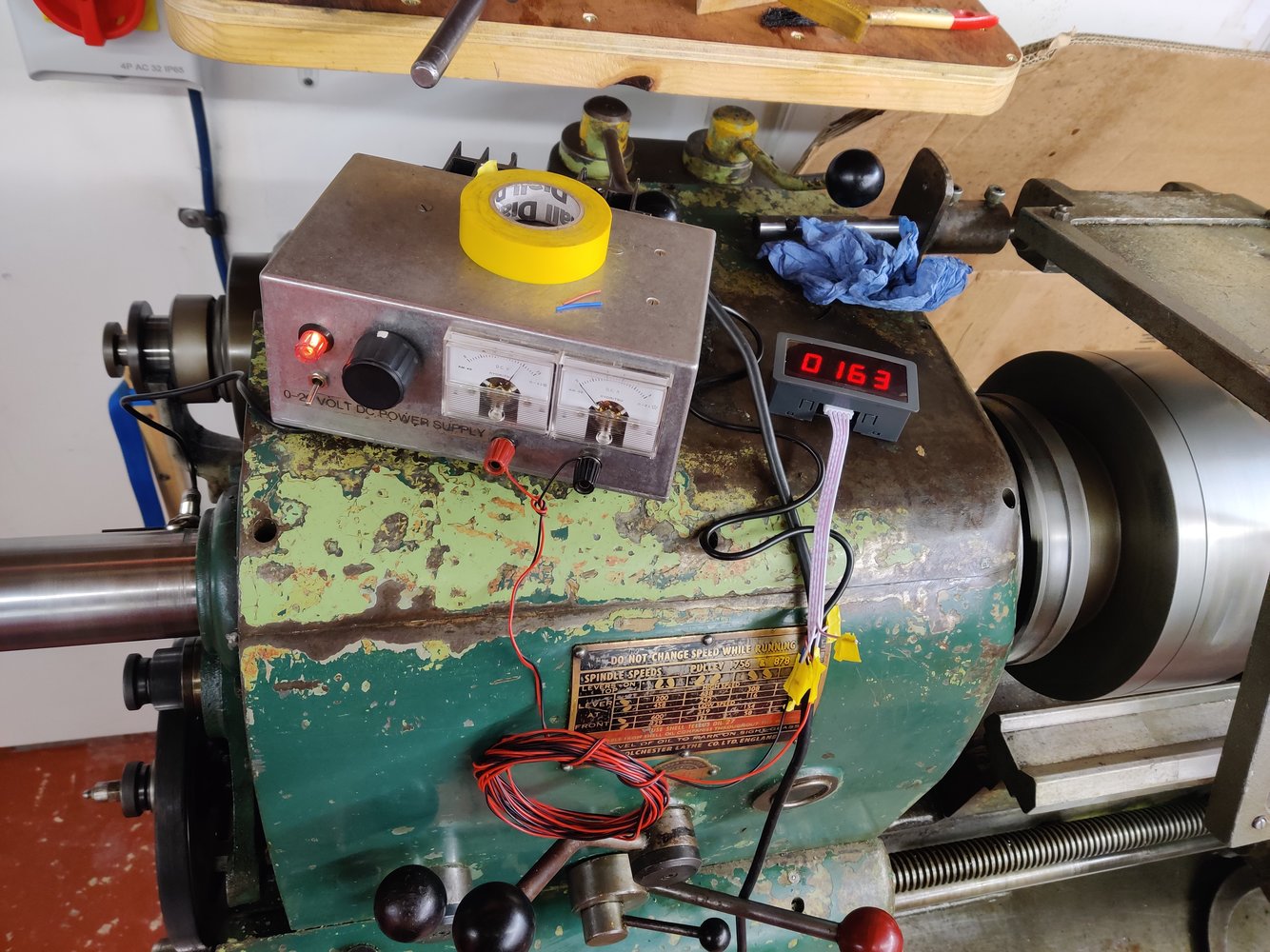

Quick test to make sure it all actually works , needed to fine tune the gap between the sensor and magnet but apart from that pretty good

Made a little bracket from scrap to hold the sensor

Box ready to be screwed under my shelf just by the headstock gear selectors, will have 8 core cable coming out for the potentiometer and display all in one nice neat cable.

Quick test to make sure it all actually works , needed to fine tune the gap between the sensor and magnet but apart from that pretty good

Made a little bracket from scrap to hold the sensor

Box ready to be screwed under my shelf just by the headstock gear selectors, will have 8 core cable coming out for the potentiometer and display all in one nice neat cable.

Well that is a nice job, but I can honestly say I never look at the speed (selected by gear) on my triumph. Perhaps I should..Making a mess milling out the box for my RPM display and potentiometer

View attachment 322250

Quick test to make sure it all actually works , needed to fine tune the gap between the sensor and magnet but apart from that pretty good

View attachment 322251

Made a little bracket from scrap to hold the sensor

View attachment 322254

Box ready to be screwed under my shelf just by the headstock gear selectors, will have 8 core cable coming out for the potentiometer and display all in one nice neat cable.

View attachment 322253

View attachment 322252

Lewis_RX8

Member

- Messages

- 1,556

- Location

- Scotland

I can use the gear table for speed but as soon as the motor frequency changes I have no idea so this should help also a lot easier to glance at than studying a table.Well that is a nice job, but I can honestly say I never look at the speed (selected by gear) on my triumph. Perhaps I should..

With more experience you probably get a feel of RPM's and feeds needed but I'm using all the help I can get while I get the hang of it

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Aye, I put the rpm meter on my Triumph but if I am honest I never look at it, I just know by experience what is right as I have used it for years by just turning the pot to get to a spindle speed.I can use the gear table for speed but as soon as the motor frequency changes I have no idea so this should help also a lot easier to glance at than studying a table.

With more experience you probably get a feel of RPM's and feeds needed but I'm using all the help I can get while I get the hang of it

Same with feeds, I didn't have a clue what the actual feedrates were until I looked the last day.

Same with feeds, I didn't have a clue what the actual feedrates were until I looked the last day.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,638

- Location

- Keeler crater

I've got no way of knowing, the vfd shows frequency so I could work out the motor speed but I don't know the ratio between the motor and the spindle. You won't bother working out the "right" speed for a given material, tool and diameter so there's not much point in knowing it.

Feeds I just do a couple of passes by hand to get a feel for it then set the feed so it looks more or less the same. It's all very scientific.

Feeds I just do a couple of passes by hand to get a feel for it then set the feed so it looks more or less the same. It's all very scientific.

Lewis_RX8

Member

- Messages

- 1,556

- Location

- Scotland

I've got no way of knowing, the vfd shows frequency so I could work out the motor speed but I don't know the ratio between the motor and the spindle. You won't bother working out the "right" speed for a given material, tool and diameter so there's not much point in knowing it.

Feeds I just do a couple of passes by hand to get a feel for it then set the feed so it looks more or less the same. It's all very scientific.

RPM's and feeds make it easier for me to go back to settings I found worked well rather than guestimating to get it close, Means I only have to do non-scientific trial and error once and then take note of it for next time working on that metal with similar dia

.

.But yea may have a point on don't do all the calculations to work out the surface speeds and cutting stuff properly just what I found works

Lewis_RX8

Member

- Messages

- 1,556

- Location

- Scotland

Turning some tool steel down today to get this holder to fit

Hoods tip to turn the vfd up as you get to smaller diameters like the CNC worked well on this started outside at about 200 RPM then adjusted as I went in to about 600 RPM kept the finish nice.

Also being hard tool steel I think that improves the finish aswell?

Chips where eer ,,, warm

Using crappy big radius cutters that came with the lathe because not a huge amount of loss to me if they chip on an interrupted cut as don't see me using them much.

Hoods tip to turn the vfd up as you get to smaller diameters like the CNC worked well on this started outside at about 200 RPM then adjusted as I went in to about 600 RPM kept the finish nice.

Also being hard tool steel I think that improves the finish aswell?

Chips where eer ,,, warm

Using crappy big radius cutters that came with the lathe because not a huge amount of loss to me if they chip on an interrupted cut as don't see me using them much.

Lewis_RX8

Member

- Messages

- 1,556

- Location

- Scotland

Thanks to @Pete. thread on the coolant pump capacitor mod

Just wired up the capacitor with the wires direct to 240v wall socket but was running really slowly lumpy could not go under any load at all it would cut out.

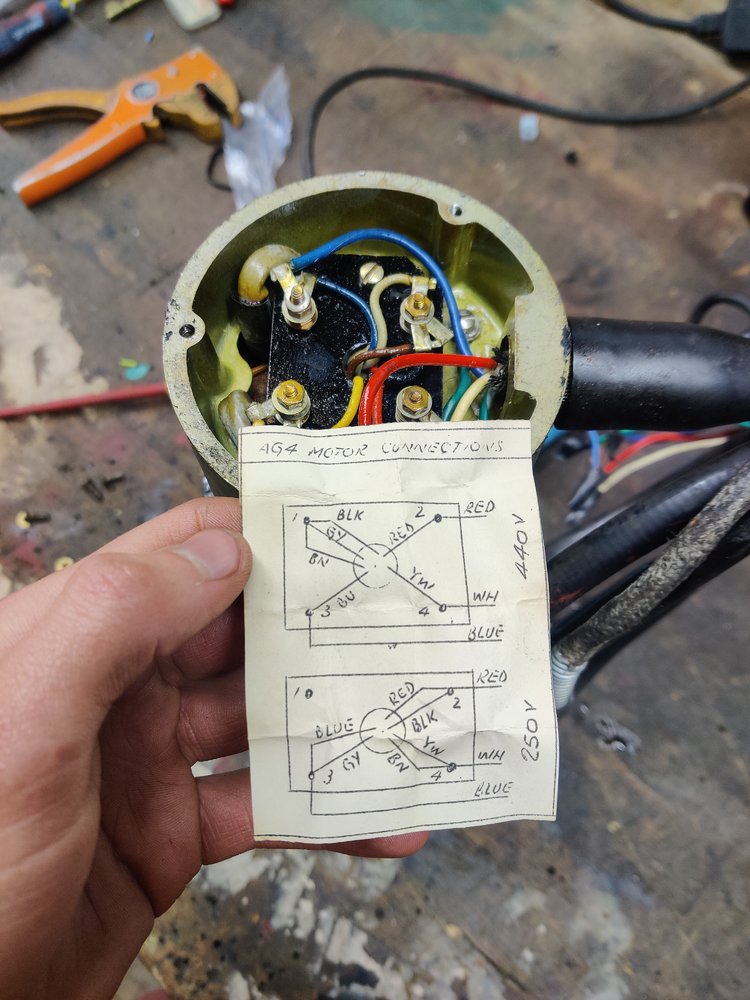

Then decided to crack it open and wow someone back in 1960 was thinking of me in this very moment this folded up paper was inside the motor terminals box , OEM I think it had not been opened

So promptly wired it to the 250v setting and suggested by the paper and what a difference sounds a good bit smoother still not VFD smooth but what can you expect from a capacitor, Dunked in a water bath and was pumping well. After cleaning the top I saw it actually said 250v/440v on the top but it was so much I didn't see. I think I am right in saying that is now in Delta connection but I am no spark lol.

Was thinking of installing it to an external tank behind the machine and piping out the original drain hole in the lowest centre point as the OEM tank was the inside of the lathe which seems a waste of space I was using as storage.

Just wired up the capacitor with the wires direct to 240v wall socket but was running really slowly lumpy could not go under any load at all it would cut out.

Then decided to crack it open and wow someone back in 1960 was thinking of me in this very moment this folded up paper was inside the motor terminals box , OEM I think it had not been opened

So promptly wired it to the 250v setting and suggested by the paper and what a difference sounds a good bit smoother still not VFD smooth but what can you expect from a capacitor, Dunked in a water bath and was pumping well. After cleaning the top I saw it actually said 250v/440v on the top but it was so much I didn't see. I think I am right in saying that is now in Delta connection but I am no spark lol.

Was thinking of installing it to an external tank behind the machine and piping out the original drain hole in the lowest centre point as the OEM tank was the inside of the lathe which seems a waste of space I was using as storage.

That's the same one fitted to my Town Woodhouse mill, has the same bit of paper inside too...Thanks to @Pete. thread on the coolant pump capacitor mod

Just wired up the capacitor with the wires direct to 240v wall socket but was running really slowly lumpy could not go under any load at all it would cut out.

View attachment 322804

Then decided to crack it open and wow someone back in 1960 was thinking of me in this very moment this folded up paper was inside the motor terminals box , OEM I think it had not been opened

So promptly wired it to the 250v setting and suggested by the paper and what a difference sounds a good bit smoother still not VFD smooth but what can you expect from a capacitor, Dunked in a water bath and was pumping well. After cleaning the top I saw it actually said 250v/440v on the top but it was so much I didn't see. I think I am right in saying that is now in Delta connection but I am no spark lol.

View attachment 322803

Was thinking of installing it to an external tank behind the machine and piping out the original drain hole in the lowest centre point as the OEM tank was the inside of the lathe which seems a waste of space I was using as storage.

What size cap did you go with?

Lewis_RX8

Member

- Messages

- 1,556

- Location

- Scotland

8uf ,, had to buy on eBay as we sold a big box of random size caps a while ago thought no use for themThat's the same one fitted to my Town Woodhouse mill, has the same bit of paper inside too...

What size cap did you go with?

Here

Lewis_RX8

Member

- Messages

- 1,556

- Location

- Scotland

Got a few bits sorted on the triumph over the holidays

Oil changed in the headstock and screwcutting gearbox

For some reason all my text is changing to italics now

Little bit of glitter sitting there but not too worried about it no idea how many years it has accumulated that over

Also had a shot at sorting out these resonance and vibrations seeing if unmatching belts caused the issue but it was not as one belt ran them just fine and all the belts have unique matching marks so I imagine they where a matched set

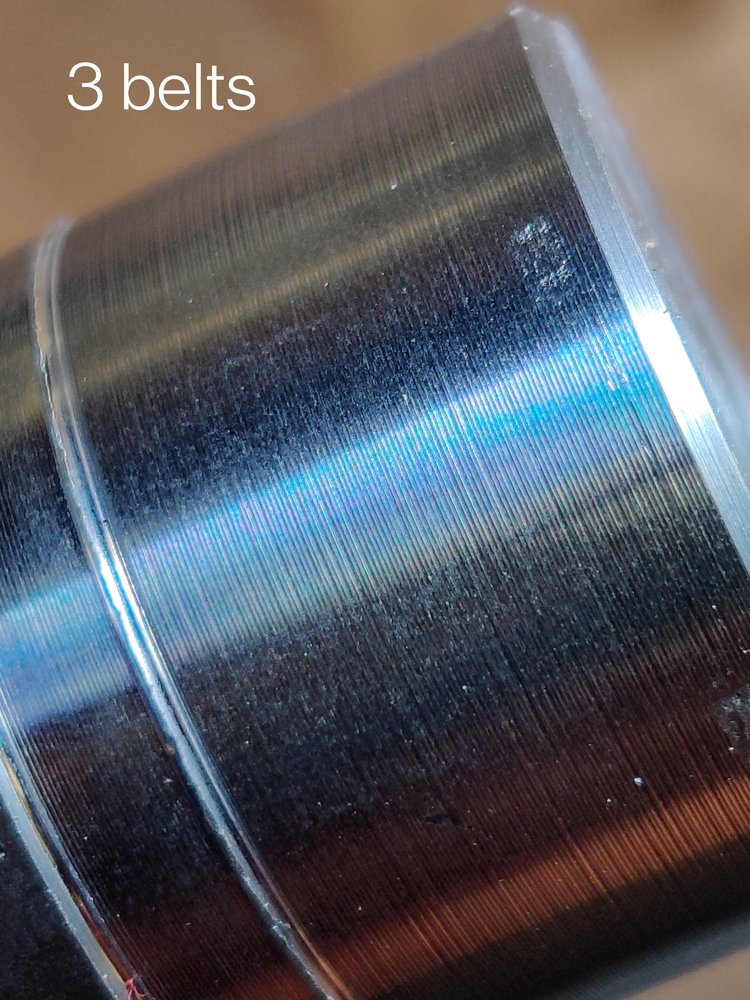

here is lines in finish with 3 belts that remained unchanged as the vibrations did when it was taken to one belt

Intresting however , When the belts where loose the vibrations where a lot lower IIRC

A quick vid of vibrations and a weird resonance at about 1000 RPM shown by my handy RPM sensor , These vibrations make it impossible to read dial guages etc when you are near resonance RPM unfortunately however the lathe was never geared to run at 1000RPM but the non two-speed ones were so quite confusing.

Think thats all to report may have more to add in the morning.

Oil changed in the headstock and screwcutting gearbox

For some reason all my text is changing to italics now

Little bit of glitter sitting there but not too worried about it no idea how many years it has accumulated that over

Also had a shot at sorting out these resonance and vibrations seeing if unmatching belts caused the issue but it was not as one belt ran them just fine and all the belts have unique matching marks so I imagine they where a matched set

here is lines in finish with 3 belts that remained unchanged as the vibrations did when it was taken to one belt

Intresting however , When the belts where loose the vibrations where a lot lower IIRC

A quick vid of vibrations and a weird resonance at about 1000 RPM shown by my handy RPM sensor , These vibrations make it impossible to read dial guages etc when you are near resonance RPM unfortunately however the lathe was never geared to run at 1000RPM but the non two-speed ones were so quite confusing.

Think thats all to report may have more to add in the morning.

prepman

Forum Supporter

- Messages

- 2,757

- Location

- Gwynedd UK

There's an issue with multiple belts. Because of slight differnces in length they don't all drive evenly. There's details somewhere on the net. My Student has one wide flat belt.Got a few bits sorted on the triumph over the holidays

Oil changed in the headstock and screwcutting gearbox

View attachment 325196

For some reason all my text is changing to italics now

Little bit of glitter sitting there but not too worried about it no idea how many years it has accumulated that over

View attachment 325197

Also had a shot at sorting out these resonance and vibrations seeing if unmatching belts caused the issue but it was not as one belt ran them just fine and all the belts have unique matching marks so I imagine they where a matched set

here is lines in finish with 3 belts that remained unchanged as the vibrations did when it was taken to one belt

Intresting however , When the belts where loose the vibrations where a lot lower IIRC

View attachment 325199

A quick vid of vibrations and a weird resonance at about 1000 RPM shown by my handy RPM sensor , These vibrations make it impossible to read dial guages etc when you are near resonance RPM unfortunately however the lathe was never geared to run at 1000RPM but the non two-speed ones were so quite confusing.

Think thats all to report may have more to add in the morning.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Will have to test mine with a tub of water and see if it is anything like yours.

Regarding the belts, supposedly if you mark across them with chalk or similar then run a while then stop and rotate by hand to find the marks and see if they still align, if they do the belts match, never tried myself.

Regarding the belts, supposedly if you mark across them with chalk or similar then run a while then stop and rotate by hand to find the marks and see if they still align, if they do the belts match, never tried myself.

That's a big assumption to make. I would take the chuck off to try it - put the small drive plate on. If the vibration is still there try a lower gear, same motor rpm. If the vibration is still there then @prepman is probably right.There's an issue with multiple belts. Because of slight differnces in length they don't all drive evenly. There's details somewhere on the net. My Student has one wide flat belt.

Seadog

Save the planet. It's the only one with rum!

- Messages

- 12,951

- Location

- NE London - UK

There's an issue with multiple belts. Because of slight differnces in length they don't all drive evenly.

I believe that you can buy matched sets.

Pete.

Member

- Messages

- 14,976

- Location

- Kent, UK

Regardless of the 'theory' multiple belts work fine . We have several machines at work that use sets of 10 belts and they just buy them by the box because they are almost a consumable on these machines.. No particular effort is made to match them in any way. I used one of them when it was brand new and it had a very expensive moulded set where all the belts were moulded together. It's lifespan was no greater or less than the loose sets.