You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Tig.. Lorch HT200

- Thread starter Brad93

- Start date

Brad93

Member

- Messages

- 19,429

- Location

- Essex, United Kingdom

Brad93

Member

- Messages

- 19,429

- Location

- Essex, United Kingdom

Brad93

Member

- Messages

- 19,429

- Location

- Essex, United Kingdom

Did you TIG'ed that frame too or did you switch to the MMA side of the force?

SARTo

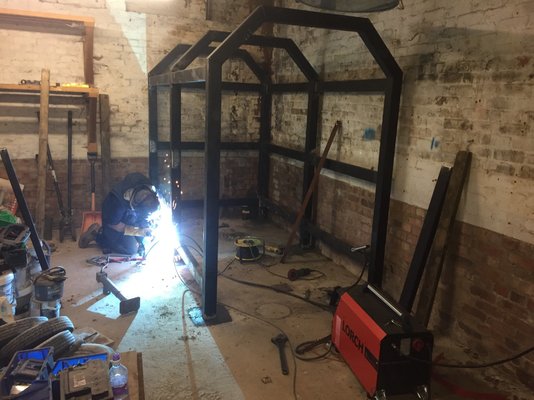

Nope migged the frame, still a Lorch though So chucked it in here save another thread.

Brad93

Member

- Messages

- 19,429

- Location

- Essex, United Kingdom

Now looking into 3 phase for the workshop rather than running off a generator, so a 300 amp machine could then be used. Will have to wait though. Think the three phase is gonna cost the best part of £3-4kYou need a Tetrix 230

Brad93

Member

- Messages

- 19,429

- Location

- Essex, United Kingdom

@matt1978 have these handytigs got a spark gap and if so does it need setting at all? I'm getting quite poor HF starts and have to keep touching the tungsten to the work before pressing the pedal to get a spark to jump.

Seems to be getting worse. I'm guessing it is a spark gap as I can hear the machine buzz.

Will quickly try a different torch to rule that out.

Getting quite Weak HF when you arc to your finger to.

Seems to be getting worse. I'm guessing it is a spark gap as I can hear the machine buzz.

Will quickly try a different torch to rule that out.

Getting quite Weak HF when you arc to your finger to.

Richard.

Member

- Messages

- 18,335

- Location

- Cambridgeshire

Possibly leaking somewhere mate.@matt1978 have these handytigs got a spark gap and if so does it need setting at all? I'm getting quite poor HF starts and have to keep touching the tungsten to the work before pressing the pedal to get a spark to jump.

Seems to be getting worse. I'm guessing it is a spark gap as I can hear the machine buzz.

Will quickly try a different torch to rule that out.

Getting quite Weak HF when you arc to your finger to.

Just out of curiosity it didn't start doing this after you give that poor speedway a "dry" run did it

Richard.

Member

- Messages

- 18,335

- Location

- Cambridgeshire

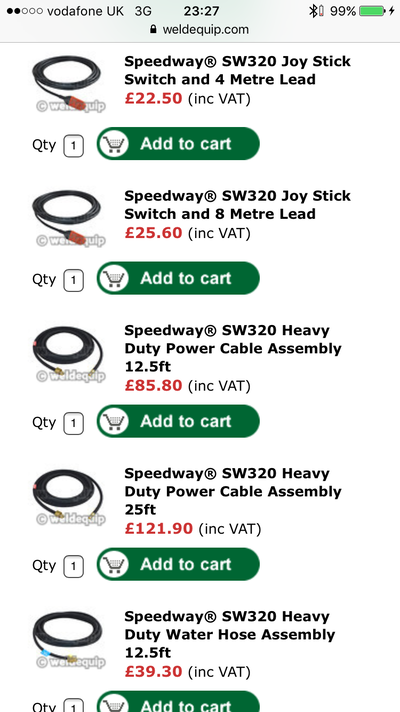

That's easy enough. Bring a socket out on a short lead of the back of the cooler and plug your welder into the cooler. Run it through the on/off switch on the cooler and plug your cooler in the wall. This way the welder can only be turned on if there is power to the cooler and the cooler is running.Ck is working fine.

Now I need to fit some sort of safety where the cooler has to be on

Brad93

Member

- Messages

- 19,429

- Location

- Essex, United Kingdom

A different dinse has improved things a little but I'm still having some issues. I haven't got any HFT tungsten at the minute I'm just using 2% Lanth, and after couple of arc starts (DC) I then start having the issues on uncontaminated tungsten.

Got to be the torch.

Got to be the torch.

Unsure of how to drill the hole though, as they seem to be tapered holes.

Drill a small pilot hole and get a taper cutter Brad, the sort we all used to use before the stepped cutters we have today, lather it in cutting compound and drill slowly.