You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Manually forming a lot of M12 threads.

- Thread starter Gareth0123

- Start date

brightspark

Member

- Messages

- 41,473

- Location

- yarm stockton on tees

good idea but it would pull the guts out of a cordlessId make a die holder up to fit in a cordless drill.

Gareth0123

You'll need 16 pigs to do the job in one sitting!

- Messages

- 1,548

- Location

- Norwich, Norfolk, UK

Id make a die holder up to fit in a cordless drill.

Yep. I think that will be the way I will have to go; I have plenty of odd bits of tube and pipe about so it shouldn't be too difficult to make something to fit one of my cordless drills.

I use a cordless for tapping M12 all the time. Its a decent one, in low gear mind.

I use a an 18 volt cordless all the time for tapping M6, M8, M10, M12 and on occasion M16, and in each instance I prefer to use spiral flute taps.

I really don't perceive an issue using an M12 die mounted in a home-made adaptor in one of my Ryobi 18Volt cordless drills...... I have one of the heavy duty 3 range variable speed F/R drills.

Gareth0123

You'll need 16 pigs to do the job in one sitting!

- Messages

- 1,548

- Location

- Norwich, Norfolk, UK

I just tried manually running a 1/4" BSP die down a piece of 12Ø MS round bar, and it barely scratched the surface let alone cut a decent thread.

Those die holders pictured above look the business ............ would anyone care to turn me one up? ...... beer tokens are awaiting

25mm internal depth clearance from the back of the die, 3 grubscrews for the die, 3 side slots to clear swarf and a 12mm hex shank (with one end turned down to say 10Ø and then welded into place from the inside of the adaptor).

Those die holders pictured above look the business ............ would anyone care to turn me one up? ...... beer tokens are awaiting

25mm internal depth clearance from the back of the die, 3 grubscrews for the die, 3 side slots to clear swarf and a 12mm hex shank (with one end turned down to say 10Ø and then welded into place from the inside of the adaptor).

waddycall

Member

- Messages

- 2,026

- Location

- Cornwall

They're cheap..........I just tried manually running a 1/4" BSP die down a piece of 12Ø MS round bar, and it barely scratched the surface let alone cut a decent thread.

Those die holders pictured above look the business ............ would anyone care to turn me one up? ...... beer tokens are awaiting

25mm internal depth clearance from the back of the die, 3 grubscrews for the die, 3 side slots to clear swarf and a 12m hex shank (with one end turned down to say 10Ø and then welded into place from the inside of the adaptor).

http://www.tracytools.com/tailstock-die-holder

123hotchef

Member

- Messages

- 14,347

- Location

- Kent

great idea

Gareth0123

You'll need 16 pigs to do the job in one sitting!

- Messages

- 1,548

- Location

- Norwich, Norfolk, UK

They're cheap..........http://www.tracytools.com/tailstock-die-holder

I doubt I could get the full 20mm thread length I want from one of those, and without cut-outs to clear the swarf they are not suitable for even short productions runs of 10-20 items which would be where I would be starting from.

Have you priced them up for someone to make them? For that quantity, you could get a real good price, especially if you don't have an urgent deadline - the saving in your time and effort would probably be worth it.

That puts me at the mercy of some else, plus moving them from A to B and back again. Although I have 500 plus to make over the next 9 months it is a time filler job I could drop onto nicely doing 10 here and 20 there as my work and time dictate.

8ob

Member

- Messages

- 14,316

- Location

- Nescient in the vale

Gareth I have just had a squint at the one that would run a 12mm thread, with a die in there is at least 15mm behind the die and the hollow shaft runs right through so no limit there. I think you would get away with welding a three sided shaft in the end and just drilling swarf clearing holes in the die holder. There is plenty of meat so would not compromise the strength.

Bob

At least 15mm behind the die.

And loads of room to weld a drill drive.

Bob

At least 15mm behind the die.

And loads of room to weld a drill drive.

Gareth0123

You'll need 16 pigs to do the job in one sitting!

- Messages

- 1,548

- Location

- Norwich, Norfolk, UK

I have decided to give one of those a pop. Even if I only get the first 15mm of the 20 mm of M12 X 1.75 I require on each bar it is still a very good start for me.

Pete's suggestion is the most sensible if you want to do this on the cheap which it looks like you do. Problem is, i really think this is being gone about ass uppards because you have a fair amount to do, this leads to the most common problem with threads done at home or by the less experienced. Squareness is key and essential to a good thread with loading and longevity, threads that are not square lead to unequal loading and things failing (doesn't really apply in your case particularly) but its a good practice to have the basic knowledge.

There is nothing wrong with tackling this manually but you need to keep those threads square to make you life easy and to get repeatable results, without being able to achieve repeatability you will get frustrated fast, trouble starting the threads, threads being drunk as a lord. This makes it a harder/ longer and a lot more frustrating process to produce acceptable results.

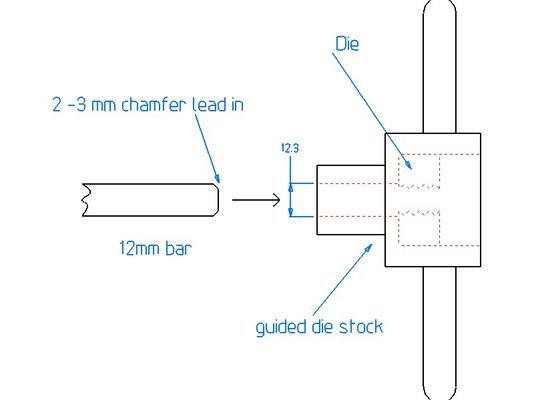

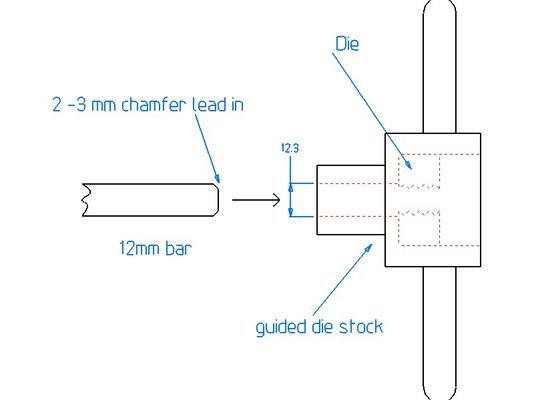

The key here is you need to guide the die squarely, Exactly the same as per conduit die stocks. They are made idiot proof so it can't go wrong and that makes life a whole lot easier and which is as per the drawing below.

I can quote on doing these as i have just the right gear to do the job with the actual thread cutting taking literally seconds, bit there is more to consider. I would suggest you think about the drawing below and see if a homer here wants to look at making you one on the cheap. This will be your best bet to produce these economically (for a manual operation at least) and with repeatable results. There is more than one way to skin a cat but i feel this is your best option given what you have said.

There is nothing wrong with tackling this manually but you need to keep those threads square to make you life easy and to get repeatable results, without being able to achieve repeatability you will get frustrated fast, trouble starting the threads, threads being drunk as a lord. This makes it a harder/ longer and a lot more frustrating process to produce acceptable results.

The key here is you need to guide the die squarely, Exactly the same as per conduit die stocks. They are made idiot proof so it can't go wrong and that makes life a whole lot easier and which is as per the drawing below.

I can quote on doing these as i have just the right gear to do the job with the actual thread cutting taking literally seconds, bit there is more to consider. I would suggest you think about the drawing below and see if a homer here wants to look at making you one on the cheap. This will be your best bet to produce these economically (for a manual operation at least) and with repeatable results. There is more than one way to skin a cat but i feel this is your best option given what you have said.

Last edited:

Someone may have already mentioned that threads are rolled and not normally cut.

Who told you that? Threads are rolled but they are cut equally as often and more so in most engineering shops. It's about application and cost. Please check your source of info before posting stuff like that. This is how incorrect info gets out the net, people read it and think its true. It makes the guys like me, life long in the trade cringe, at all the misinformation spread about.

RIP

Kairo

- Messages

- 3,030

- Location

- Netherlands

Hey, sorry, I posted that on my phone so I couldn't go into detail and I didn't notice that Gareth doesn't need the threads to be strong.Who told you that? Threads are rolled but they are cut equally as often and more so in most engineering shops. It's about application and cost. Please check your source of info before posting stuff like that. This is how incorrect info gets out the net, people read it and think its true. It makes the guys like me, life long in the trade cringe, at all the misinformation spread about.

Cold forming of materials like threads is year one engineering, so I wouldn't normally reference something like that. I've only ever seen cut threads on small volume special parts and on large diameter studding (which even feels sharp in your hands). Cut threads will be weaker so it makes sense that they would not normally be used. This was confirmed to me during projects, I recall a chassis designer telling off a technician for cutting threads, and my machinist also avoiding cut threads stating same reasons. I am talking about male threads here, I don't know about female threads.

Last edited:

RIP

Kairo

- Messages

- 3,030

- Location

- Netherlands

Quick Google says that commercial male threads are rolled, female threads are cut. That finally explains why it's always the nut that shearsHey, sorry, I posted that on my phone so I couldn't go into detail and I only cursively read the post so I didn't notice that Gareth doesn't need the threads to be strong.

Cold forming of materials like threads is year one engineering, so I wouldn't normally reference something like that. I've only ever seen cut threads on small volume special parts and on large diameter studding (which even feels sharp in your hands). Cut threads will be weaker so it makes sense that they would not normally be used. This was confirmed to me during projects, I recall a chassis designer telling off a technician for cutting threads, and my machinist also avoiding cut threads stating same reasons. I am talking about male threads here, I don't know about female threads.

Gareth0123

You'll need 16 pigs to do the job in one sitting!

- Messages

- 1,548

- Location

- Norwich, Norfolk, UK

I have been manually cutting threads with taps and dies for 40 odd years and the swarf on the floor testifies to that ………… I had never rolled threads until March of this year when I purchased a M2.5 and M3 thread roller for rethreading stainless steel bicycle spokes after cutting them to length for the custom built wheels I require.

My initial issue is starting the die off square when the 2 metre long pieces of 12Ø bar are held horizontally in the vice: I have no problems with the additional 1 metre sections which are clamped vertically in my vice and are much easier for me to both judge square and work the die holder.

I have purchased a set of the above shown die holders and they have arrived before 9.30am this morning. The die I want to use is an M12 X 1.75 X 1” and the die holder suitable for this has a 12.5mm shank so it does fit in my cordless pistol drill, but the back clearance on the die in the holder is around 5mm, so I am getting around 15mm thread length on my 12Ø bar, and I can easily finish this off manually with another die in a standard handle. This second die will be my M12 X 1.75 X 1½” in a suitable handle: alas the 1½” die holder that also arrived this morning has a 16Ø hollow shank and although it allows 12Ø bar to fit through it will not fit into the 13mm chuck of my cordless drill.

As for doing this job on the cheap, that is not my objective unless you count not being able to justify the purchase cost of a lathe and all the tooling entailed to do this job, means that I am a cheapskate.

I have set a materials cost of £3.50 per support which at quantity 500 is a budget of £1750.00 overall, and that includes the 2metre x 12Ø MS steel bar, M12 BZP connector nut, the two other pieces I am making and welding to each support and galvanising ……….. But does not include my time/labour, which I am supplying to myself free of charge.

The cost of the galvanising is presently looking a bit precarious. This is because it is 27 miles each way for me to the nearest galvanisers who will only accept a minimum job of 500kg or more; these supports weigh 2kg each, so I will need to take a batch of 250 for galvanising each time, and then I will be subject to a 25p per item small items handling fee and this alone will be £62.00, plus galvanising (by net weight), plus VAT then add on 27miles X 4 which is there and back to deliver, and then there and back to collect. I am seriously considering a baking soda cleaning bath and Zinc electroplating at my workshop. Recently I have been changing seawater cruiser/fishing boat anodes and in the last month alone I have acquired just over 100kg of scrap zinc. A little experimental foray into the realm of electroplating has proven to be successful, although I get a somewhat greenish finish which

My initial issue is starting the die off square when the 2 metre long pieces of 12Ø bar are held horizontally in the vice: I have no problems with the additional 1 metre sections which are clamped vertically in my vice and are much easier for me to both judge square and work the die holder.

I have purchased a set of the above shown die holders and they have arrived before 9.30am this morning. The die I want to use is an M12 X 1.75 X 1” and the die holder suitable for this has a 12.5mm shank so it does fit in my cordless pistol drill, but the back clearance on the die in the holder is around 5mm, so I am getting around 15mm thread length on my 12Ø bar, and I can easily finish this off manually with another die in a standard handle. This second die will be my M12 X 1.75 X 1½” in a suitable handle: alas the 1½” die holder that also arrived this morning has a 16Ø hollow shank and although it allows 12Ø bar to fit through it will not fit into the 13mm chuck of my cordless drill.

As for doing this job on the cheap, that is not my objective unless you count not being able to justify the purchase cost of a lathe and all the tooling entailed to do this job, means that I am a cheapskate.

I have set a materials cost of £3.50 per support which at quantity 500 is a budget of £1750.00 overall, and that includes the 2metre x 12Ø MS steel bar, M12 BZP connector nut, the two other pieces I am making and welding to each support and galvanising ……….. But does not include my time/labour, which I am supplying to myself free of charge.

The cost of the galvanising is presently looking a bit precarious. This is because it is 27 miles each way for me to the nearest galvanisers who will only accept a minimum job of 500kg or more; these supports weigh 2kg each, so I will need to take a batch of 250 for galvanising each time, and then I will be subject to a 25p per item small items handling fee and this alone will be £62.00, plus galvanising (by net weight), plus VAT then add on 27miles X 4 which is there and back to deliver, and then there and back to collect. I am seriously considering a baking soda cleaning bath and Zinc electroplating at my workshop. Recently I have been changing seawater cruiser/fishing boat anodes and in the last month alone I have acquired just over 100kg of scrap zinc. A little experimental foray into the realm of electroplating has proven to be successful, although I get a somewhat greenish finish which

Last edited:

- Messages

- 24,127

- Location

- Birmingham

This second die will be my M12 X 1.75 X 1½” in a suitable handle: alas the 1½” die holder that also arrived this morning has a 16Ø hollow shank and although it allows 12Ø bar to fit through it will not fit into the 13mm chuck of my cordless drill.

Can you tap the hollow shank and fit a threaded bar small enough to go in the chuck?