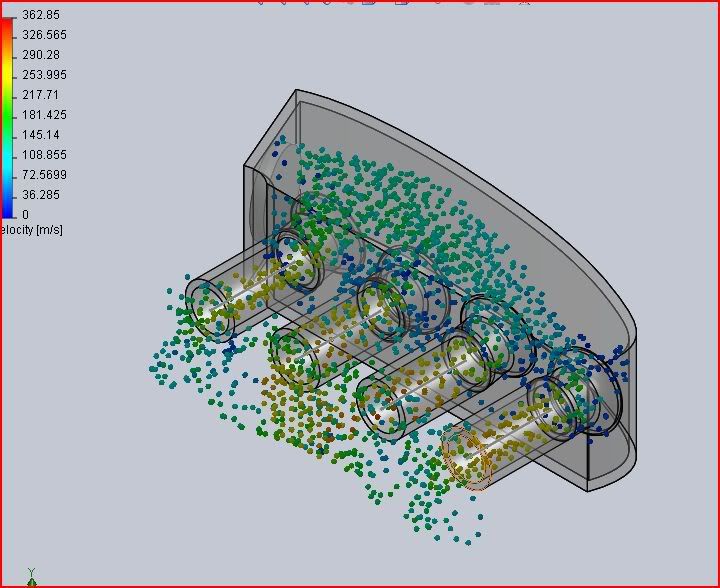

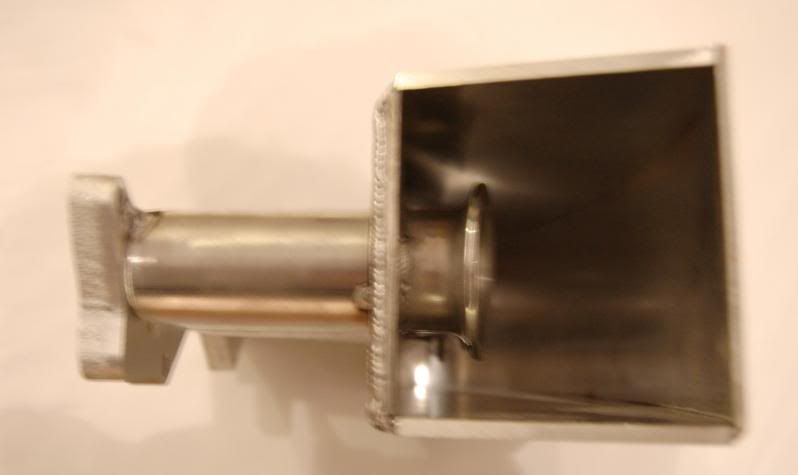

hi, nice work with the manifolds, what basis did you design your inlet from, how did you know how much volume and how much to taper it off etc? how much would it cost for you to part with some of them stacks? to save me having to mess around and turn some?

what id are the stacks?

Have you thought of making a flare, to form the bellmouth from tube

Do you mean to roll them from flat tube? This was the best design I could come up with for the application, cost didn't come into it all that much, its nice to make things cheaper, but the customer will pay all the costs, and would rather not skimp on £40-50 here and there if it will make even a slight difference to performance