You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

M18 battery repair

- Thread starter JOEPRO

- Start date

MattF

Forum Supporter

- Messages

- 18,630

- Location

- South Yorkshire

but there's a bunch of people on Youtube taking them apart saying the bms is there but it's dissabled

They've proven so, rather than merely speculating?

They've proven so, rather than merely speculating?

They sound convincing to me, do tests etc..

But again, I don't know enough stuff about snall circuts to judge

Kram

Member

- Messages

- 8,520

- Location

- Sussex

Slightly unrelated but my shaver has stopped working, opened it up and there was a bad connection from the battery tabs to the PCB. A little disapointed to see the 18650 was only a 1200mAh cell so I removed it for now.

Whats the best cell I can easily get, to put in it? The Parkside cells are not much better from previous experience of swapping 2Ah cells. I'd like to find a good 2.5 or 3Ah if I can find one.

Whats the best cell I can easily get, to put in it? The Parkside cells are not much better from previous experience of swapping 2Ah cells. I'd like to find a good 2.5 or 3Ah if I can find one.

Slightly unrelated but my shaver has stopped working, opened it up and there was a bad connection from the battery tabs to the PCB. A little disapointed to see the 18650 was only a 1200mAh cell so I removed it for now.

Whats the best cell I can easily get, to put in it? The Parkside cells are not much better from previous experience of swapping 2Ah cells. I'd like to find a good 2.5 or 3Ah if I can find one.

I have tested the Parkside cells and they always test at 2Ah or more, the same as a samsung cell from a makita battery.

Kram

Member

- Messages

- 8,520

- Location

- Sussex

Mine were from a new 12v 2Ah pack of three cells and they were not even close. 1.6-1.7A/h. I could use them but if I could find a 3Ah cell it would nearly double the run time.I have tested the Parkside cells and they always test at 2Ah or more, the same as a samsung cell from a makita battery.

I'm thinking even a 21700 could fit in there.

Interesting stuff, any details on the Makita XGT? I was initially using the batteries down to the cutoff but now try to swap them out as they hit 1 bar left. I could drain one and measure it.Milwaukee don’t balance, like most tool manufacturers, it’s only Makita and that’s why they are generally a bit more £ per Ah.

View attachment 510439View attachment 510440View attachment 510441

I suppose that means the chinese fakita batteries are less likely to catch fire than the originals?

J1nx

Member

- Messages

- 684

- Location

- Somerset UK

The XGT uses a far more complex BMS, I think it will take a while for the community to catch up with these. I think it’s safe to assume that individual cell balancing is certain. They may well use dynamic LVP dependent on load.Interesting stuff, any details on the Makita XGT? I was initially using the batteries down to the cutoff but now try to swap them out as they hit 1 bar left. I could drain one and measure it.

I suppose that means the chinese fakita batteries are less likely to catch fire than the originals?

The fakes may cut out at a ‘safer’ LVP setting however I wouldn’t expect the cells to be anywhere near the quality and imo that’s the biggest issue. Secondly I wouldn’t trust the monitoring to be as good in any other regard, the low voltage will not cause a fire, it may damage the cell (if left in this state) and it will degrade it quicker but other issues such as overcharging are the mechanism for combustion in li-ion cells usually. For fakes the bus bar and connections are also often of concern.

Personally I only use a couple of 2Ah batteries and mostly 5/6Ah, the 3Ahs are really a bit of a dud in the range imo. The 5Ah’s have the best current output impedance so i generally prefer these even over the 6s.

Note the 9 & 12Ah LXT batteries are due release here in the next few weeks, finally!

Slightly unrelated but my shaver has stopped working, opened it up and there was a bad connection from the battery tabs to the PCB. A little disapointed to see the 18650 was only a 1200mAh cell so I removed it for now.

Whats the best cell I can easily get, to put in it? The Parkside cells are not much better from previous experience of swapping 2Ah cells. I'd like to find a good 2.5 or 3Ah if I can find one.

18650 Batteries | Fogstar UK

18650 Battery Retailer l FREE uk shipping l Same day shipping if ordered before 3pm l Authenticated and batch-tested products from Molicel, Samsung and Sony.

take your pick, plenty to chose from

that site is supposed to be good, all legit cells etc... (there's a lot of fakes about)

Mine were from a new 12v 2Ah pack of three cells and they were not even close. 1.6-1.7A/h. I could use them but if I could find a 3Ah cell it would nearly double the run time.

I'm thinking even a 21700 could fit in there.

Not sure what configuration that is, probably 3s.

I only use the x20v packs which are 5s 2p configuration.

I have stripped them and used the cells to rebuild makita battey packs and they have always tested at least at 2ah.

Milwaukee don’t balance, like most tool manufacturers, it’s only Makita and that’s why they are generally a bit more £ per Ah.

View attachment 510439View attachment 510440View attachment 510441

Where did this info come from?

The Makita info is completely wrong. All the LXT batteries from 3Ah to 6Ah use 18650 cells in a 5s 2p configuration.

They are different capacities to give you different overall battery outputs.

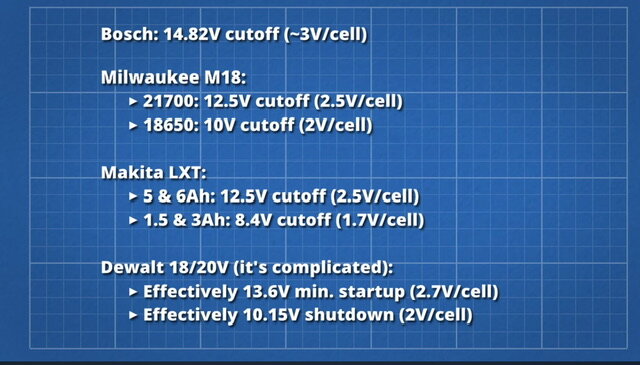

But the minimum voltage of all of them when fully discharged is limited by the BMS board to 3.4 volts per cell. Once it hits this figure the BMS cuts power to the tool to protect the cells.

I don't know where their figures of 1.7 and 2.5v come from.

The absolute minimum of a 18650 cell is 2.5v, anything below this and you will damage the cell. Quality protected cells will cut output to the terminals if you try to discharge them further.

Kram

Member

- Messages

- 8,520

- Location

- Sussex

Where did this info come from?

The Makita info is completely wrong. All the LXT batteries from 3Ah to 6Ah use 18650 cells in a 5s 2p configuration.

They are different capacities to give you different overall battery outputs.

But the minimum voltage of all of them when fully discharged is limited by the BMS board to 3.4 volts per cell. Once it hits this figure the BMS cuts power to the tool to protect the cells.

I don't know where their figures of 1.7 and 2.5v come from.

The absolute minimum of a 18650 cell is 2.5v, anything below this and you will damage the cell. Quality protected cells will cut output to the terminals if you try to discharge them further.

3.4v is well above where most LVC will operate, I've not known anything to cut out above 3v before?!

With current Li-ion tech, the manufactuers specify the cut out as low as 1.7v, some 2v. I was also suprised by that as its pointless - theres amost zero energy left in a cell below 3v, so why bother, but its in the datasheets.

I'd be happier if all my tool batteries cut out at 3v (unloaded) or slightly higher.

Some info states that cells above 1v can be charged but the initial charge should be extremely low current until its back to normal safe voltages.

J1nx

Member

- Messages

- 684

- Location

- Somerset UK

Wrong? You’ve lost me there fella, I certainly haven’t claimed the LXT packs have currently used anything other than 18650. The 1.5 and 2Ah batteries use a single string of 5 cells but yes the others are parallel.Where did this info come from?

The Makita info is completely wrong. All the LXT batteries from 3Ah to 6Ah use 18650 cells in a 5s 2p configuration.

They are different capacities to give you different overall battery outputs.

Interesting, 3.4V still has significant charge remaining, even at no load. If a loaded tool was to cut at 3.4V you would get almost no runtime.But the minimum voltage of all of them when fully discharged is limited by the BMS board to 3.4 volts per cell. Once it hits this figure the BMS cuts power to the tool to protect the cells.

Makita generally stop via in tool protection, the LVP in the battery is a secondary protection in the star system tools.

Which manufacturers data sheet are you referring to? 2.5V is stated on the Murata sheets I can see. The decision by Makita to use 1.7 on the lower capacity cells does raise eyebrows, it’s likely to stop high load tools tripping early but it is beyond design specs and not advised. This is why most people buy the 5Ah batteries for professional work (lower output impedance than all, even the 6Ahs).I don't know where their figures of 1.7 and 2.5v come from.

The absolute minimum of a 18650 cell is 2.5v, anything below this and you will damage the cell.

No tool manufacturers use protected cells.Quality protected cells will cut output to the terminals if you try to discharge them further.

These are generally aftermarket cells modified and used in Vapes etc. All the tool brands use a battery based BMS, not protected cells.

Try here if you need a bit more info…

J1nx

Member

- Messages

- 684

- Location

- Somerset UK

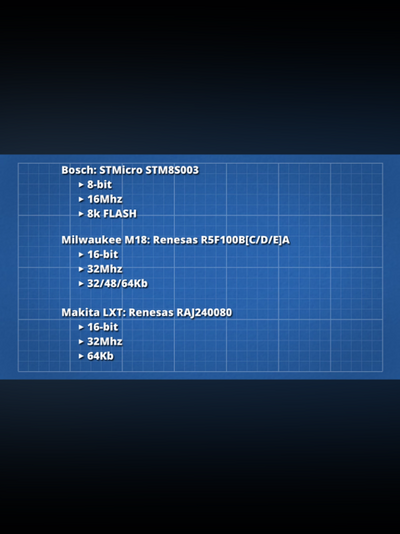

For anyone interested here is the just released Tool Scientist’s video on obtaining the data from Milwaukee batteries. British YouTuber buyitfixit started the ball rolling and now after serious effort a group of contributors have cracked it. You don’t quite get the data that Makita record but then these have less processing power and no balancing. The data obtained is still pretty useful.

The Milwaukee batteries are notoriously flakey and getting warranty replacements can be a struggle so this could be very useful.

Looks like it’s best to avoid the 8 and 12Ah batteries as even low cycle counts show bad imbalances, however the 340A discharge on the 12Ah in the video is pretty impressive.

The Milwaukee batteries are notoriously flakey and getting warranty replacements can be a struggle so this could be very useful.

Looks like it’s best to avoid the 8 and 12Ah batteries as even low cycle counts show bad imbalances, however the 340A discharge on the 12Ah in the video is pretty impressive.