You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lorch

- Thread starter John G McMillan

- Start date

matt1978

www.lorch.eu

- Messages

- 3,939

- Location

- UK, Cannock

If you use a gas cooled torch you have to put a bridge across pins 4-5 in the amphonel, otherwise you will get an error code E5 (unless you go in the sub menu and tell it it’s gas cooled but turning the cooler off)

But Johns machine is around 9 years old and I don’t know what software version it has, the sub menu for physically telling it you want to turn the cooler off was on later releases, which is why the bridge across pins 4-5 was the default wiring in all Lorch gas cooled torches

But Johns machine is around 9 years old and I don’t know what software version it has, the sub menu for physically telling it you want to turn the cooler off was on later releases, which is why the bridge across pins 4-5 was the default wiring in all Lorch gas cooled torches

Richard.

Member

- Messages

- 18,043

- Location

- Cambridgeshire

The tweco has a menu where you can tell it there is a cooler and if you do that it needs to see water going through the flow switch or you’ll get an error but you don’t need to link pins out with the tweco you either turn it on or off. If it’s turned off you can use the cooler as a “separate” item. So you have the cooler powered up and running continuously. Only down side to that would be if you did get a blockage it wouldn’t kill the welder and save your torch.

Blockages on the lorch cooler are absolutely possible because the design is a bit poor (sorry Matt)

The exit from the tank is pointing directly down offering a gravity fed head to the pump. Any foreign bodies at all will be going straight in there. I fit a filter on to mine and maybe lorch have started doing this too but I had a block happen with it.

Blockages on the lorch cooler are absolutely possible because the design is a bit poor (sorry Matt)

The exit from the tank is pointing directly down offering a gravity fed head to the pump. Any foreign bodies at all will be going straight in there. I fit a filter on to mine and maybe lorch have started doing this too but I had a block happen with it.

matt1978

www.lorch.eu

- Messages

- 3,939

- Location

- UK, Cannock

Yes it’s the same in the Lorch software but the default setting is that it’s “on” and so if you get it from straight from the box and use a non Lorch torch unless the pins are linked out you will get a E5 code after about 5 Seconds of welding

John G McMillan

New Member

- Messages

- 5

- Location

- Cornwall UK

I have another three weeks at sea before I chech out the settings on this lorch but the manual clearly says that user specific menu C2 is de activation of the error message,it says if the deactivation is switched to on the error message e05 00 no longer appears ,I am getting the error message so the default from the factory must be off.O how I miss my 205,ha ha.

matt1978

www.lorch.eu

- Messages

- 3,939

- Location

- UK, Cannock

Yes like I said, the default setting means that it will look for a cooler. Which is why all lorch gas cooled torches have pins 4-5 bridged out in the amphonel. It’s more so that in the future If you use a cooler it will work correctly and not lead to any damage of the torch if there are any flow restrictions, if this was already deactivated in the menu then it wouldn’t pick it up.

It’s no problem at all to fit an aftermarket torch but it’s just easier to bridge out then pins. Job done.

It’s no problem at all to fit an aftermarket torch but it’s just easier to bridge out then pins. Job done.

Richard.

Member

- Messages

- 18,043

- Location

- Cambridgeshire

Ah ok yes well I knew that was there I have mine set up to work with the cooler.That’s the kiddo

I thought you meant it was a clever hidden menu secret lorch code thingy for bypassing the lorch torch.

The tweco doesn’t care what torch goes on it which is why I thought it was different.

Richard.

Member

- Messages

- 18,043

- Location

- Cambridgeshire

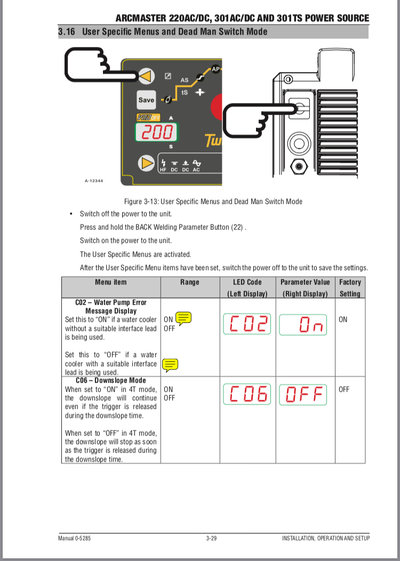

Looking again at the instructions C2 must be set to ON if you want it not to look for a cooler and OFF if you want it to work properly with a cooler.

On the tweco the default setting actually has this set to ON so deactivated. Looks like there are some differences between them so don’t trust my manual too much.

On the tweco the default setting actually has this set to ON so deactivated. Looks like there are some differences between them so don’t trust my manual too much.

Hello everyone.

Sorry for my bad english but im desperate so i have to write

I have T220 ac/dc and got message E25 on my display.

Don`t know what to do. The nearest service is in Serbia or Croatia so it is not profitable to go there.

I have some friends who knows about electronic but they don`t know where to look so if you can help me with some expirience and advice.

Thank you and wish you a good health.

Sorry for my bad english but im desperate so i have to write

I have T220 ac/dc and got message E25 on my display.

Don`t know what to do. The nearest service is in Serbia or Croatia so it is not profitable to go there.

I have some friends who knows about electronic but they don`t know where to look so if you can help me with some expirience and advice.

Thank you and wish you a good health.

wyn

Member

- Messages

- 3,762

- Location

- Cardiff

The E25 code usually appears when the tig torch is earthing against the bench etc when the machine is turned on.

Make sure your tungsten or torch is NOT touching the Bench when turning the machine on.

I've done that a couple of times, i always rest the torch on a glove now when switching on the T220.

Richard.

Member

- Messages

- 18,043

- Location

- Cambridgeshire

Brad as per usual is absolutely on the money E25 is displayed when the unit senses a short between the + and the - when first started up.

Common cause is tungsten in contact with the bench. Lift torch and restart the machine.

If that doesn’t cure it then the short is somewhere else. Completely remove the torch and work return from the sockets and restart to see if that clears it.

It’s a safety feature rather than an error.

Here’s a full list of the error codes for the T

Common cause is tungsten in contact with the bench. Lift torch and restart the machine.

If that doesn’t cure it then the short is somewhere else. Completely remove the torch and work return from the sockets and restart to see if that clears it.

It’s a safety feature rather than an error.

Here’s a full list of the error codes for the T

I can walk trough the menu normaly but when i finish there is E25 again.

Tryed in stick mode too.

Tryed to reset it but always, after few moments i turn it on, there is E25.

I am just afraid it can be connected with IGBT modules. They are expencive as hell.

Tomorow i will disassembe it with friend of mine and will try to see the situation inside.

Tryed in stick mode too.

Tryed to reset it but always, after few moments i turn it on, there is E25.

I am just afraid it can be connected with IGBT modules. They are expencive as hell.

Tomorow i will disassembe it with friend of mine and will try to see the situation inside.