You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Just a few tweaks to get it running :-) ........got a bit carried away !!! XS650 Makeover

- Thread starter lchris21

- Start date

lchris21

Member

- Messages

- 2,010

- Location

- South Wales

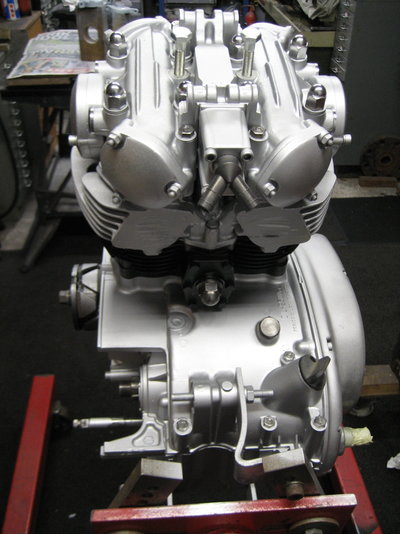

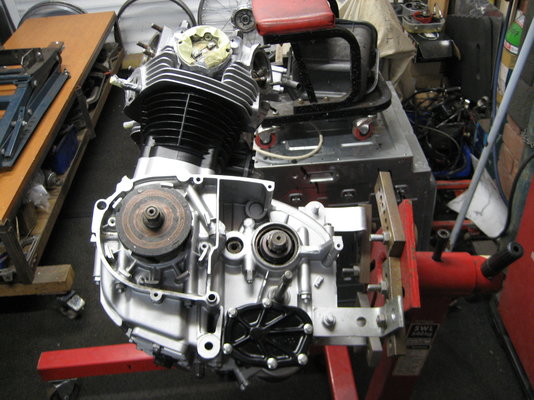

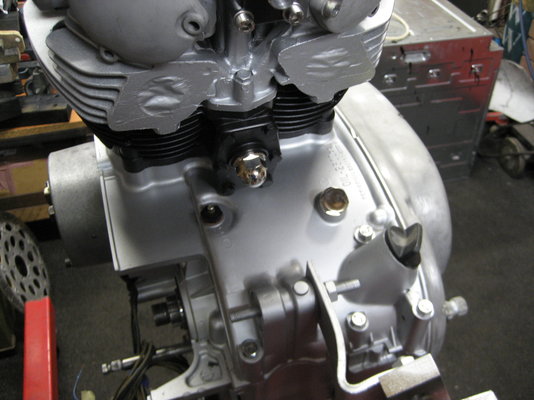

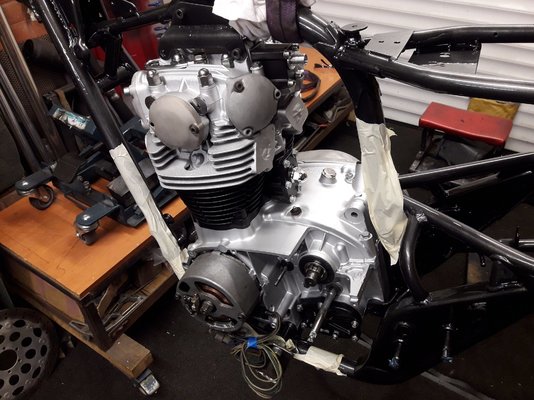

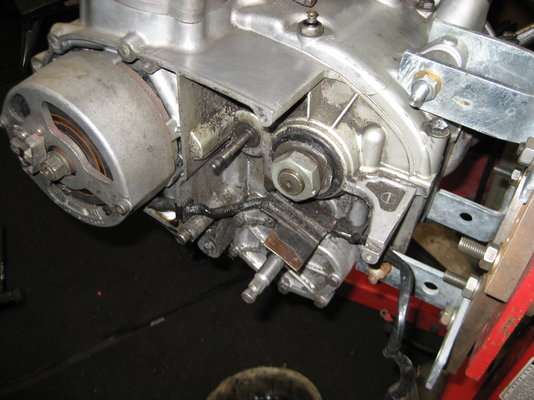

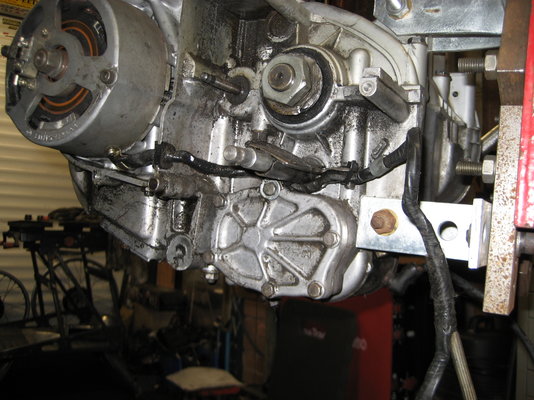

Back to it...where was I?..........the engine. My favorite part of any build is the detailing on the engine!!........probably the most satisfying part turning a rusty, leaking lump into something a bit more appealing. This was no exception, lots of leaks and lots of rust. Decreasing, power washing, sand blasting and lots of scrubbing

lchris21

Member

- Messages

- 2,010

- Location

- South Wales

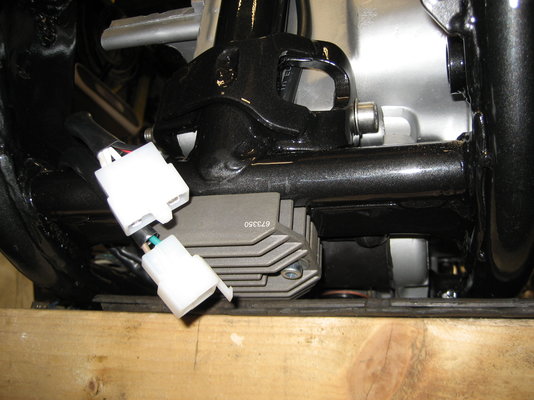

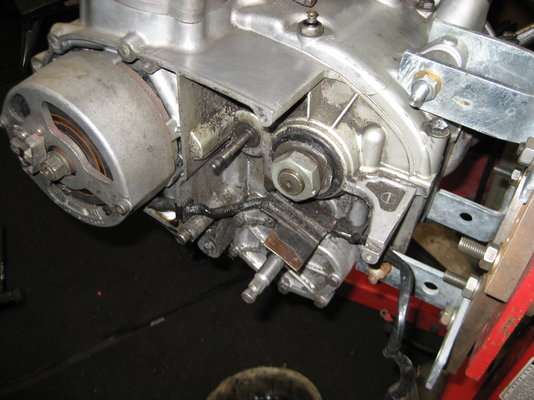

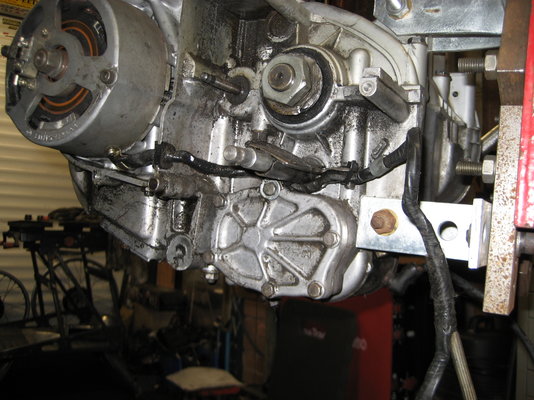

The engine cases............

Had some mixed results over the years with the wrinkle finish paint I like to use. its very hit and miss. Its requires some real heavy coats which is sometimes difficult to control. These were no exception........eventually the paint stripper was deployed after 3 attempts

Had some mixed results over the years with the wrinkle finish paint I like to use. its very hit and miss. Its requires some real heavy coats which is sometimes difficult to control. These were no exception........eventually the paint stripper was deployed after 3 attempts

lchris21

Member

- Messages

- 2,010

- Location

- South Wales

After years of losing bits and bobs and the poor turn around time in my local platers I did some research on home plating kits, and whats needed.

Must say I was a little skeptical, but as I found out cleanliness and preparation is the key, a bit like a paint job.............and you cannot polish a #### as they say

I've been refining my setup and this was the first attempt which turned out ok. The ultrasonic cleaner was being used to heat the nickle plating solution, I've since setup up an old baby bottle warmer for the same task

Must say I was a little skeptical, but as I found out cleanliness and preparation is the key, a bit like a paint job.............and you cannot polish a #### as they say

I've been refining my setup and this was the first attempt which turned out ok. The ultrasonic cleaner was being used to heat the nickle plating solution, I've since setup up an old baby bottle warmer for the same task

slim_boy_fat

Member

- Messages

- 29,363

- Location

- Scottish Highlands

After years of losing bits and bobs and the poor turn around time in my local platers I did some research on home plating kits, and whats needed.

Must say I was a little skeptical, but as I found out cleanliness and preparation is the key, a bit like a paint job.............and you cannot polish a #### as they say

I've been refining my setup and this was the first attempt which turned out ok. The ultrasonic cleaner was being used to heat the nickle plating solution, I've since setup up an old baby bottle warmer for the same task

That is seriously impressive!

Do you have a link to the kit you used, or are they all pretty much of a muchness, with no discernible difference in results, even across differing price ranges?

lchris21

Member

- Messages

- 2,010

- Location

- South Wales

That is seriously impressive!

Do you have a link to the kit you used, or are they all pretty much of a muchness, with no discernible difference in results, even across differing price ranges?

bought all the materials separately as opposed to a full kit which comes with rubber gloves goggles and other misc stuff ive already got. had a power supply already. theres loads of info online on what and what not to do. as I said cleaning is the key. bought my stuff from youplate.co.uk. the seemed pretty helpful and were quick answering questions. initial outlay was probably equivalent to the cost of a couple of good plating batches but at least I know I'll get it all back.......

I'll post a how I do it in a separate section when i get time

lchris21

Member

- Messages

- 2,010

- Location

- South Wales

Its been a few weeks....work is getting in the way

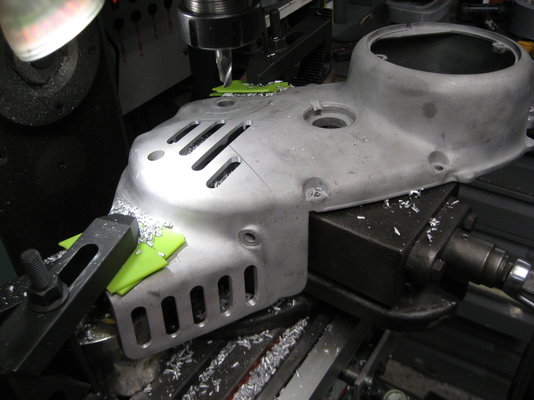

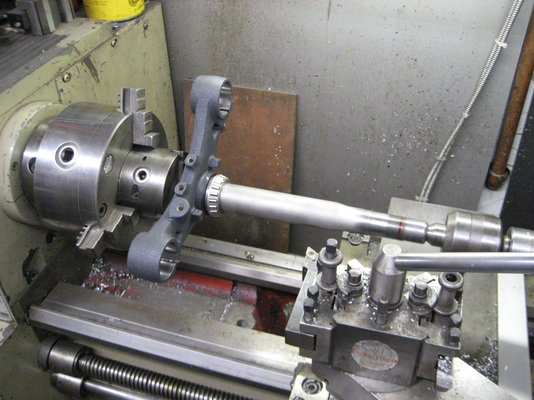

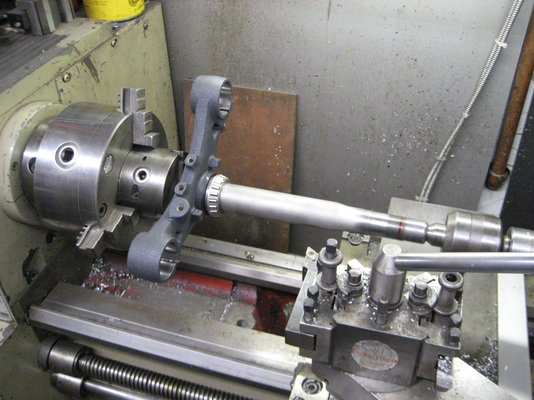

On to the steering head. A problem Id thought about then promptly forgotten about was sorting out the locknut assembly and covering up the nuts which were visible when the top clamp was in place. Bit of machining later and a cover sorts this out. Wanted to reduce the nuts to one, add a locking grubscrew into it, and then machined a fancy alloy securing screw Aprilia style for the top. The scabby finish from the casting porosity during powdercoating finally got to me so this was removed later

On to the steering head. A problem Id thought about then promptly forgotten about was sorting out the locknut assembly and covering up the nuts which were visible when the top clamp was in place. Bit of machining later and a cover sorts this out. Wanted to reduce the nuts to one, add a locking grubscrew into it, and then machined a fancy alloy securing screw Aprilia style for the top. The scabby finish from the casting porosity during powdercoating finally got to me so this was removed later

lchris21

Member

- Messages

- 2,010

- Location

- South Wales

Time to get that Ducati disc mounted and the hub centralised between the fork legs.

After blasting it I was going to mask it up then just simply repaint it.....but the though of all those little nooks and crannies with no paint got to me so ended up machining all the bobbins out to to it properly. Ordered a set of stainless replacement and set about tidying up the disc.

After blasting it I was going to mask it up then just simply repaint it.....but the though of all those little nooks and crannies with no paint got to me so ended up machining all the bobbins out to to it properly. Ordered a set of stainless replacement and set about tidying up the disc.