Dcal

Forum Supporter

- Messages

- 4,077

- Location

- Antrim Northern Ireland

I've made 3 over the years, only for small pieces but the principle is the same. The first was using a frame from an old tyre vulcanizer (bought for £1 at a Beaulieu auction) that used old forklift truck wheels. It worked well but was very heavy and not used much so sold off.

Recently made one using a G clamp and a few shaped bearings and another that uses the drill press. I've

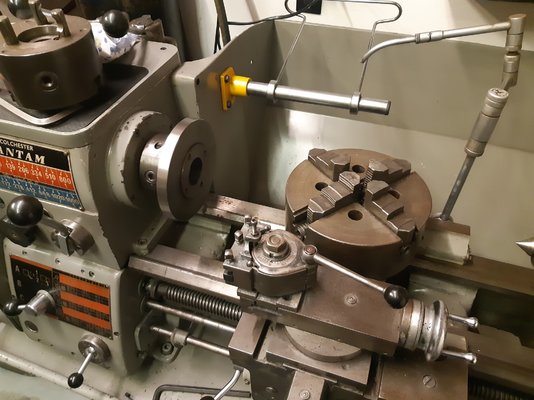

had success with mine but only for small pieces View attachment 218808 View attachment 218809 View attachment 218810

The underlying principle seems to be to make things so tough and heavy to prevent flexing in the frame that the machine ends up massive and takes up loads space. I did come across this on the net an idea that answers this problem and seems to be a very good solution. This uses a cheap ready made frame and rollers wedged between the roof and floor of his workshop.

That's a brilliant bit of lateral thinking @truckdoctor

Love the way you just knock up a wheel to suit what your doing.

I take your point on the amount of room a wheel can take up.

I'm thinking of bolting legs / channel for a pallet truck to to the frame so I can move mine about and as it's steel it would be easy to weld on a couple of hinges to bolt it to a wall so it would only take up 200mm when not in us (unbolt the legs first) but where do I find a bit of unused wall?